Reelmaster 5010- H Hydraulic SystemPage 4 - 47

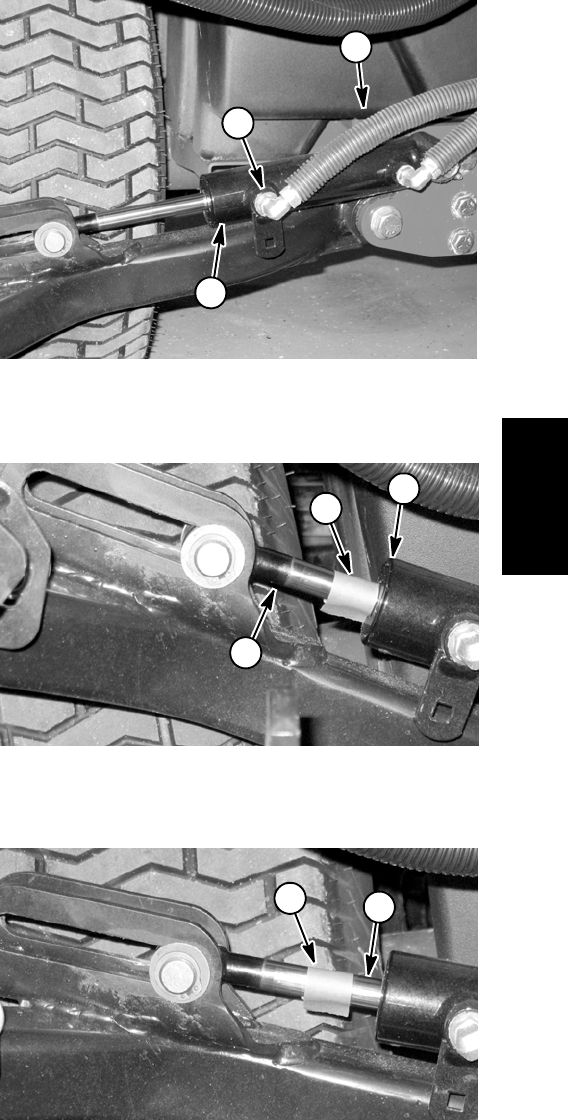

4. Thoroughly clean the area around the end of the hy-

draulic hose at ther od end of the lift cylinder for the sup-

ported lift arm. Disconnect the hydraulic hose from the

lift cylinder rod end fitting (Fig. 44).

IMPORTANT: When capping lift cylinder fitting and

hydraulic hose end, use a steel cap and plug to en-

sure that fluid leakage will not occur. Plastic plugs

will not hold hydraulic pressure that will be devel-

oped during this test p rocedure.

5. Place a steel cap on the open lift cylinder fitting to

seal the lift cylinder. Also, install a steel plug in the open

endof thedisconnected hoseto preventleakageor con-

tamination.

6. Slowly lower the jack and remove it from under the

lift arm. The cutting unit s hould settle slightly and then

be supported by the capped lift cylinder.

7. Mark theposition ofthelift cylinderrod atthe liftcylin-

der head with a piece of tape (Fig. 45).

8. Leave the machine parked for two (2) hours and

monitor the lift cylinder. The weight of the cutting unit

may cause the lift cylinder to gradually extend. Use the

tape location to determine lift cylinder rod movement

(Fig. 46).

A. If lift cylinder rod movement is less than 1.250”

(31.7 mm)after two(2) hours,makesurethat thecut-

ting unit has not settled to the ground. If the cutting

unitis stillsuspendedafter two(2)hoursand liftcylin-

der rod movement is less t han 1.250” (31.7 mm),

consider that the lift cylinder is in good condition. A

cylinder in good, usable condition will show minimal

movement.

B. Rod movement in excess of 1.250” (31.7 mm) af-

ter two (2) hours indicates that the lift cylinder may

have internal seal damage or excessive wear. Re-

move and inspect the lift cylinder (see Lift Cylinder

and Lift Cylinder Service in the Service and Repairs

section of this chapter).

9. Once lift cylinder condition has been determined,

use a jack to raise the lift arm slightly which will remove

the load from the lift cylinder. Allow the jack to support

the lift arm and to prevent it from lowering. Remove the

capfromthecylinderfittingandtheplugfromthehy-

draulic hose. Connect the hydraulic hose to the lift cylin-

der fitting.

10.Remove jack from under the lift arm. Start engine

and operate lift cylinders through several up and down

cycles. Stop the engine and check for any hydraulic

leakage.

11.If needed, repeat steps3 through 9 forother lift cylin-

ders.

12.After lift cylinder testing is completed, check oil level

in hydraulic reservoir and adjust as necessary.

1. Lift cylinder (#5 shown)

2. Cylinder rod end fitting

3. Hydraulic hose

Figure 44

3

2

1

1. Lift cylinder rod

2. Lift cylinder head

3. Tape (initial position)

Figure 45

2

1

3

1. Tape (after 2 hours) 2. Cylinder rod movement

Figure 46

2

1

Hydraulic

System