Reelmaster 5010- H

Cutting Units

Page 7 - 14

Service and Repairs

Cutting Reel Motor

NOTE: If electrical problems exist with a cutting reel

motor, a fault should have occurred that would be indi-

cated by a fault code on the InfoCenter Display. Before

considering that reel motor service work is necessary,

check for anyexisting faultcodes thatindicate problems

withareelmotor.

IMPORTANT: When performing service or mainte-

nance on the cutting reel motors, take care to not

damage the motors or electrical connections.

For information on removal, installation and service of

the cutting unit motors, see Cutting Reel Motor and Cut-

ting Reel Motor Service in the Service and Repairs sec-

tion of Chapter 5 - Electrical System.

The cutting unit side plates (Fig. 19) have threaded in-

sertsatt he locationsused forthecapscrews thatsecure

the reel motor. Check the condition of the threaded in-

sertswheneverthecuttingreel motoris removedandre-

place inserts if damage is found. Inserts should be

torquedfrom 35to 40ft- lb(48to 54N-m) during instal-

lation.

For proper lubrication ofthe reel motorsplines,a grease

fitting (item 3 in Fig. 19) must be installed in the cutting

unit side plate on the reel motor side of the cutting unit.

On the non- drive side plate, a set screw (item 4 in Fig.

19) should be installed so that it is flush with the side

plate surface.

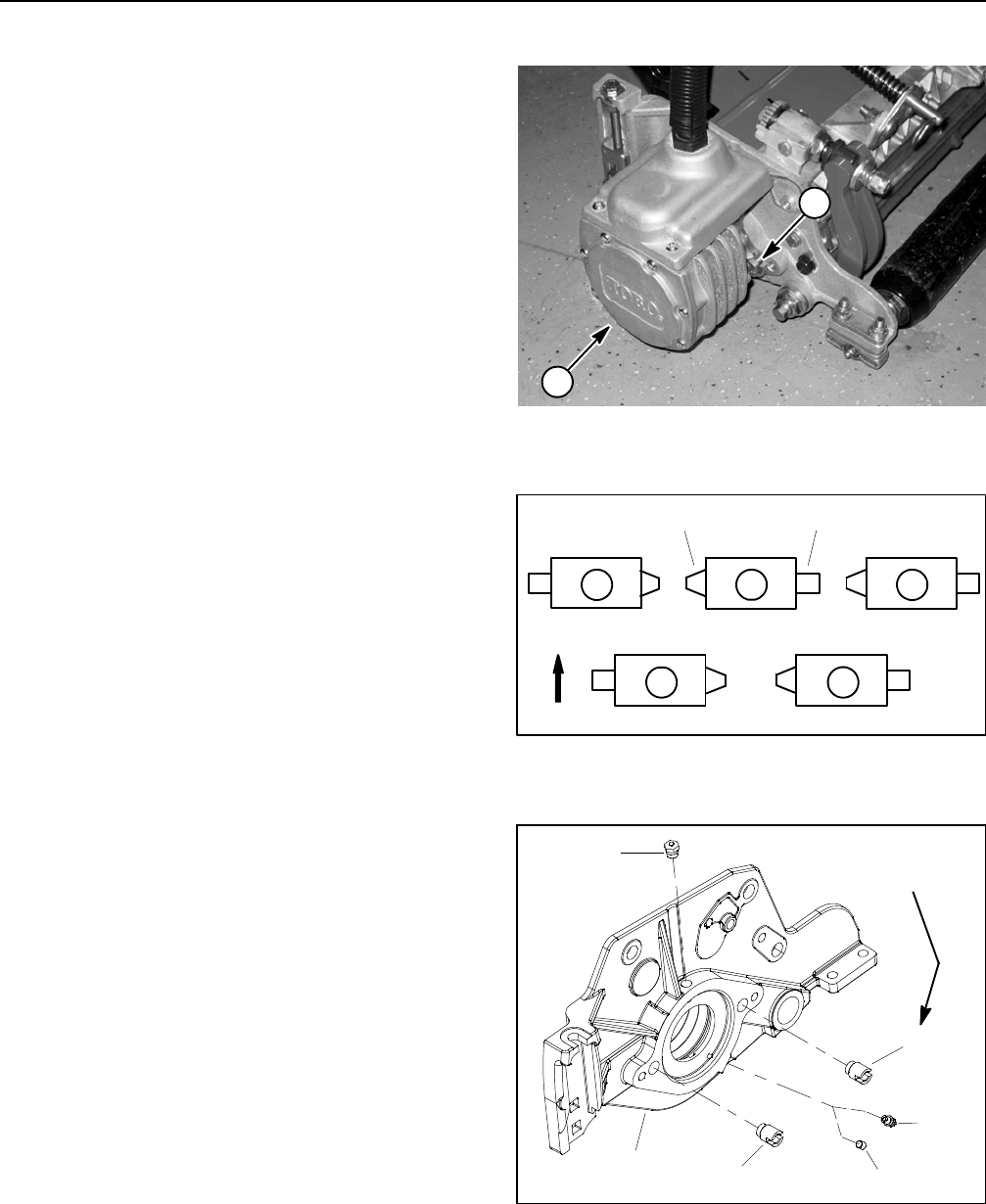

NOTE: RefertoFigure18forcorrectplacementofcut-

ting unit reel motors and weights.

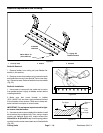

1. Cutting reel motor 2. Cap screw (2 used)

Figure 17

1

2

1. Reel motor location 2. Weight location

Figure 18

FRONT

4 1 5

32

12

1. Side plate (LH shown)

2. Threaded insert

3. Grease fitting

4. Set screw

5. Relief fitting

Figure 19

2

3

1

5

4

2

35 to 40 ft- lb

(48to54N-m)