Reelmaster 5010- H Page 5 - 73 Electrical System

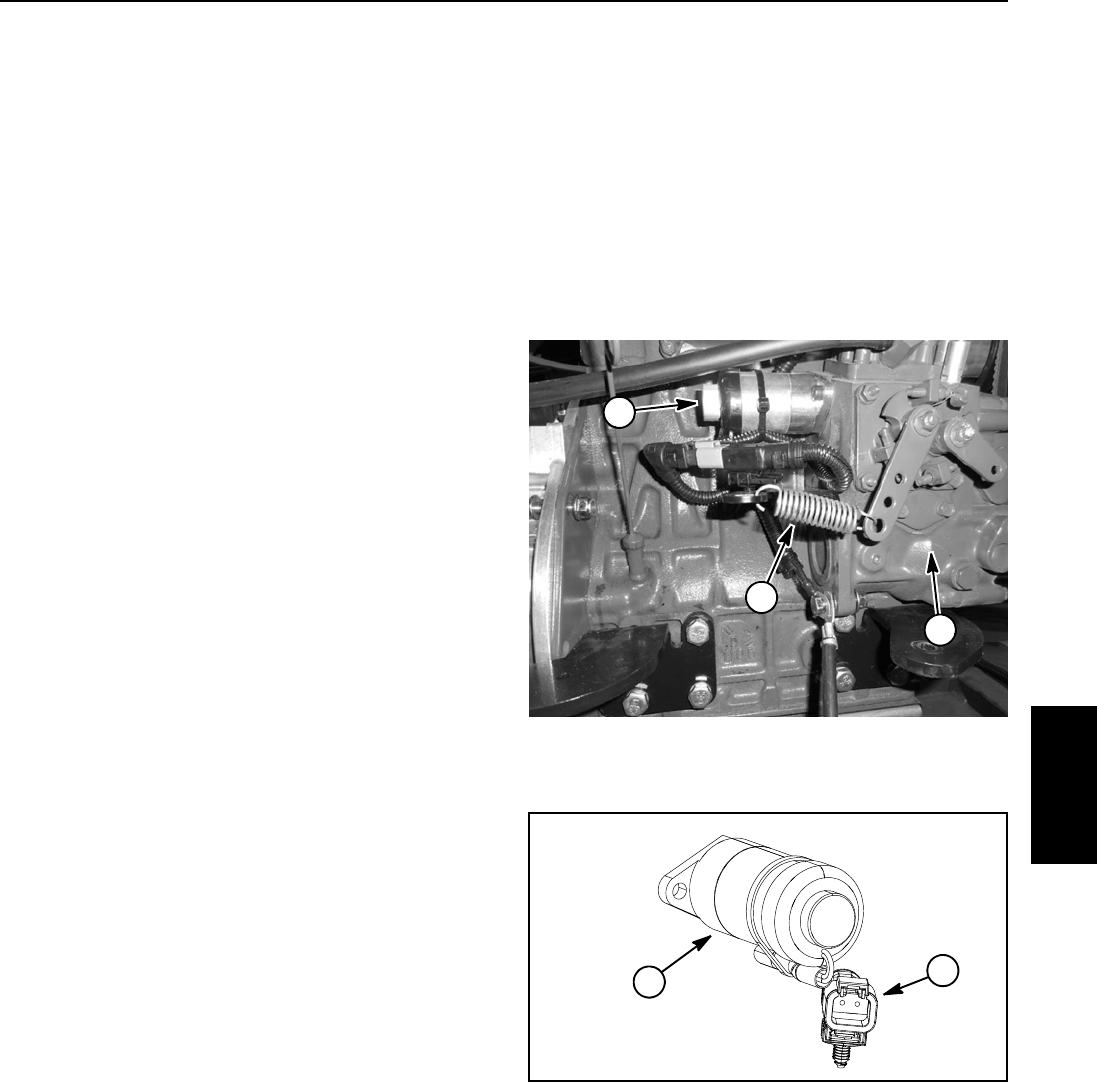

Fuel Actuator

The fuel actuator used on your Reelmaster must be en-

ergized by the TEC controller f or the diesel engine to

run. The actuator is mounted to the injection pump on

theengine(Fig.76).

The fuel actuator and TEC controller work together to

maintain engine speed by adjusting the fuel delivery to

the engine. A sensor in the motor/generator provides

thegenerator/enginespeed totheTEC controllervia the

CAN- bus.Ifthere isa changein enginespeed(e.g. load

conditions change, engine speed switch pressed byop-

erator), the TEC controller modifies the electrical output

to theactuator whichadjustsfuel asrequiredto maintain

engine speed.

The TECcontrollermonitors theoperationof thefuel ac-

tuator. If the TEC controller detected a fuel actuator

problem during engine operation, the InfoCenter Dis-

play can be used to identify the fault (see Fault Codes

in the Troubleshooting section in this chapter).

NOTE: If a problem with the fuel actuator or circuit

wiringexists, theextensionspring attachedto theactua-

tor bracket andenginespeed controlleverwill cause the

engine to run at high idle (3150 RPM) with the engine

mechanical governor maintaining engine speed. In this

situation, the control arm mounted engine speed switch

will not change enginespeed and a faultcode should be

displayed on the InfoCenter Display.

Testing

1. Park the machine on a level surface, engage the

parking brake, lower the cutting units and stop the en-

gine. Remove the key from the ignition switch. Open

hoodtogainaccesstoengine.

2. Locate fuel actuator and disconnect wire harness

connector from fuel actuator.

NOTE: The fuel actuator may be tested in place or

removed from the engine for testing.

3. If the actuator is removed from the engine, make

sure that the actuator plunger moves freely and is free

of dirt, debris and corrosion.

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the test leadstogether. Theme-

ter will display a small resistance value (usually 0.5

ohms or less). This resistance is due to the internal re-

sistance of the meter and test leads. Subtract this value

from the measured value ofthe componentyou aretest-

ing.

4. Using a multimeter (ohms setting), measure resis-

tancebetween thetwo terminalsin thefuel actuatorcon-

nector. Resistance should be from 5.0 to 5.5 ohms.

5. If ac tuator coil resistance is incorrect, replace fuel

actuator.

6. When testingiscomplete, connectwireharnesscon-

nector to the fuel actuator.

7. Lower and secure hood.

1. Injection pump

2. Fuel actuator

3. Extension spring

Figure 76

1

2

3

1. Fuel actuator 2. Actuator connector

Figure 77

1

2

Electrical

System