Reelmaster 5010- H Hydraulic SystemPage 4 - 13

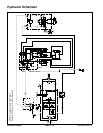

Traction Circuit

The hydraulic traction circuit consists of a variable dis-

placementpiston pump(P3) connectedin aclosed loop,

parallelcircuitto two(2) orbitalrollervane wheelmotors.

The piston (traction) pump input shaft is rotated by a

drive shaft connected to the motor/generator shaft that

is driven by the engine flywheel.

Traction circuit pressure (forward and reverse) can be

measured at test ports located in the hydraulic tubes

that connect the front wheel motors.

NOTE: In high load traction situations, the 48 VDC mo-

tor/generator may automatically assist the engine to

maintain piston (traction) pump input speed.

Forward Direction (Fig. 11)

Pushing the top of the traction pedal angles the piston

(traction) pump swash plate to create a flow of oil. This

oil flow is directed to the wheel motors via hydraulic

hosesand tubesto drive thewheels intheforward direc-

tion. Forward traction pressure is limited to 3625 PSI

(250bar) bythe forwardtraction reliefvalve (R3)located

in the piston (traction) pump.

Oil flowing from the wheel motors returns to the variable

displacement pump and is continuously pumped

through the traction circuit as long as the traction pedal

is pushed.

The angle of the swashplate determines pumpflow and

ultimately traction speed. When the traction pedal is de-

presseda smallamount,a smallswash platerotationre-

sults inlowpump outputand lowertractionspeed.When

the traction pedal is depressed fully, the pump swash

plate rotates fully to provide maximum pump output and

traction speed.

Gear pumpsection (P2) suppliesoil flow forthe steering

circuit and also provides a constant supply of charge oil

totheclosedlooptractioncircuit. This charge oil pro-

videslubricationfortractioncircuitcomponentsand also

replenishes traction circuit oil that is lost due to internal

leakage in the traction circuit.

The hydraulic reservoir provides fluid for the gear pump

(P2) through the suction hose. Charge pump flow is di-

rected to the low pressure side of the closed loop trac-

tion circuit. Charge pressure is limited by the charge

relief valve (R5) located in the piston (traction) pump.

Thechargereliefpressureis200PSI(14bar).

The piston pump (P3) includes a flushing valve that

bleeds off a small amount of hydraulic fluid for cooling

of theclosed loop traction circuit. The chargesystem re-

plenishes oil that is bled from the traction circuit by the

flushing valve.

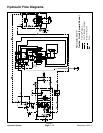

Reverse Direction

The traction circuit operates essentially the same in re-

verse as it does in the forward direction. However, t he

flow through the circuit is reversed. Pushing the bottom

of the traction pedal rotates the piston (traction) pump

swash plate to create a flow of oil. This oil is directed to

the wheel motors to drive the wheels in the reverse

direction. Reverse traction pressure is limited to 3625

PSI (250 bar) by the reverse traction relief valve (R4) lo-

cated in the piston (traction) pump.

Oil flowing from the wheel motors returns to the piston

(traction)pump andis continuouslypumped throughthe

closed loop traction circuit as long as the traction pedal

is pushed.

The charge circuit and flushing valve function the same

in reverse as they do in the forward direction.

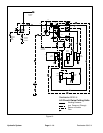

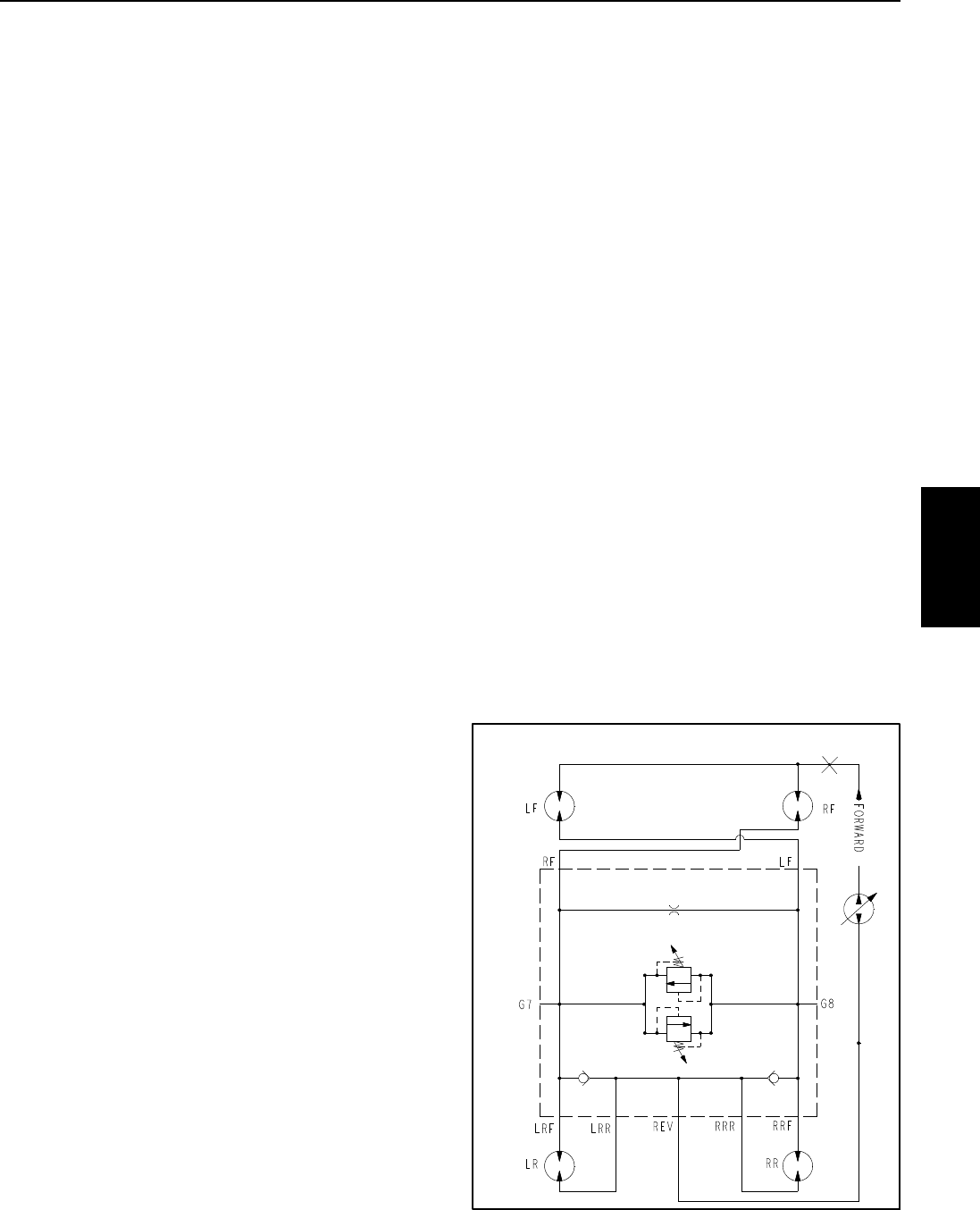

CrossTrax

TM

AWD (Optional)

On machines equipped with the optional CrossTrax

TM

AWDkit, four(4) wheelmotorsare used (Fig.12).Piston

(traction) pump flow is directed to the front tires and the

opposite rear tires to maximize traction. To reduce tire

scuffing when turning, traction system pressure is

equalized in the AWD manifold with an orifice and a bi-

directional relief valve. Check valves in the AWD man-

ifold allow the rear wheel motors to over run during tight

turns.

Figure 12

G5

CrossTrax AWD Hydraulic Schematic

TM

Hydraulic

System