Reelmaster 5010- HPage 5 - 58Electrical System

Main Power, Glow and 48 VDC Logic Relays

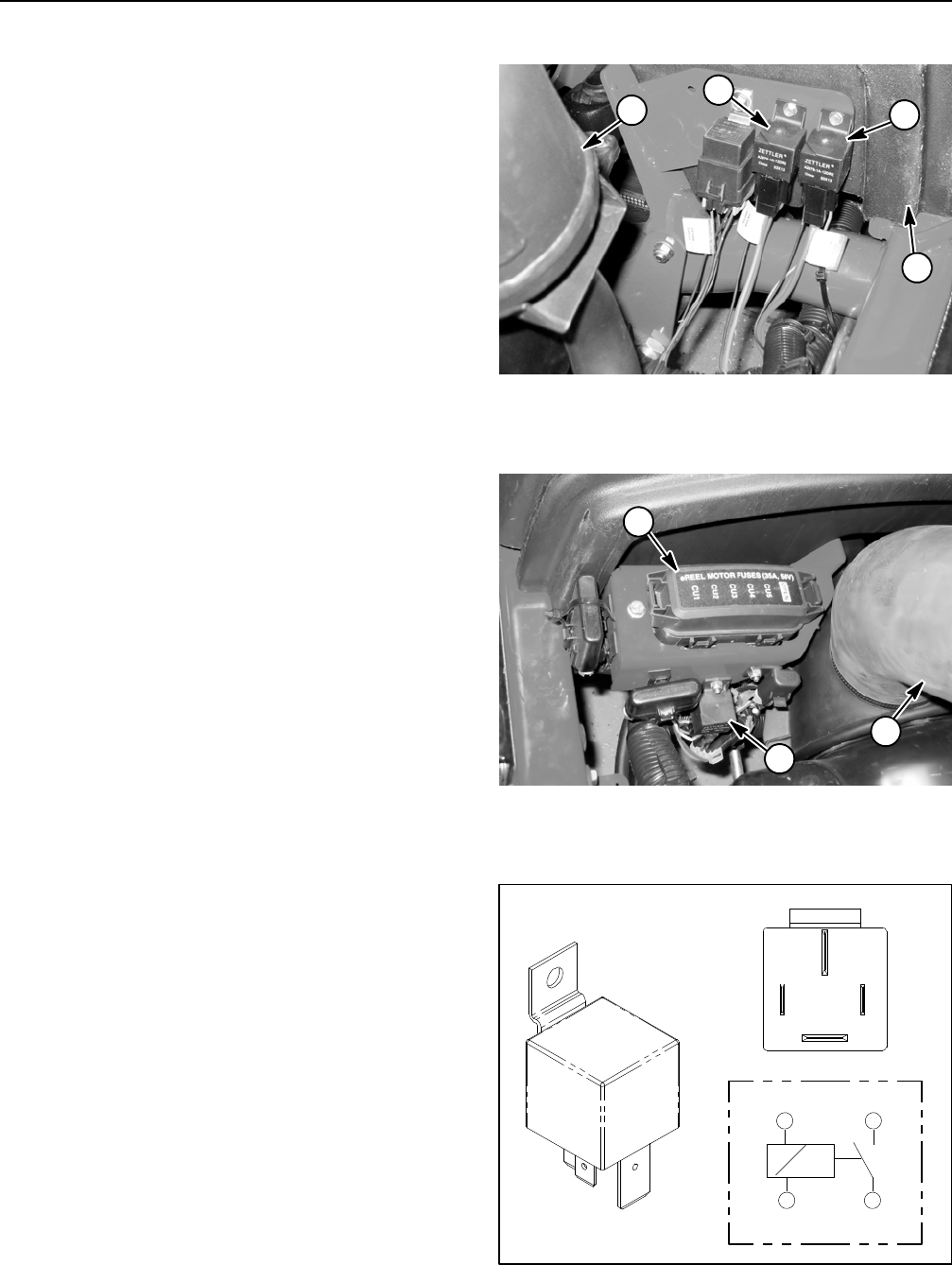

Your Reelmaster uses three (3) identical electrical re-

lays that have four (4) terminals. The main power and

glow relays are attached to a frame bracket under the

hood near the engine exhaust muffler (Fig. 50). The 48

VDC logic relay is attached toa frame bracket underthe

hood behind the reel motor fuse block (Fig. 51). A tag

near the relay harness connector identifies each relay.

The main power relay is used to provide current to the

TEC controller, headlights, power point and optional

electric equipment. When the ignition switch is in the

ON/PREHEAT or START position, the main power relay

is energized. A fault code will be displayed on the Info-

Center Display if the main power relay or circuit wiring

is faulty.

The glow relay is used to provide current to the engine

glow plugs when energized by the TEC controller. The

TEC controls and monitors the operation of the glow

relay. The glow relay and its circuit wiring should be

tested as a TEC output with the InfoCenter Display be-

fore disconnecting and testing the relay (see InfoCenter

Display in this chapter). A fault code may be displayed

on the InfoCenter Display if the glow relay or circuit

wiring is faulty.

The 48 VDC logic relay is used to provide 48 VDC logic

powerto themotor/generatorand reelmotor controllers.

It also supplies power to the main contactor in the elec-

tric reel circuit. This relay is energized byan output from

the TEC controller.

Testing

1. Park the machine on a level surface, engage the

parking brake, lower the cutting units and stop the en-

gine. Remove the key from the ignition switch.

2. Open hood to gain access to relays.

3. Locate relay and disconnect the machine wire har-

ness connector from the relay. If main power or glow re-

lay are to be removed, remove hood saddle from

machine for easier access to start relay. Remove relay

from machine for easier testing.

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small r esistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from from the measured value of the component you

are testing.

4. Verify coil resistance between terminals 85 and 86

with a multimeter (ohms setting) (Fig. 52). Resistance

should be approximately 72 ohms.

1. Exhaust muffler

2. Main power relay

3. Glow relay

4. Hood saddle

Figure 50

1

3

2

4

1. 48 VDC logic relay

2. Reel motor fuses

3. Generator air intake

Figure 51

2

3

1

Figure 52

86 87

85 30

85 86

87

30