Reelmaster 5010- H

Cutting Units

Page 7 - 26

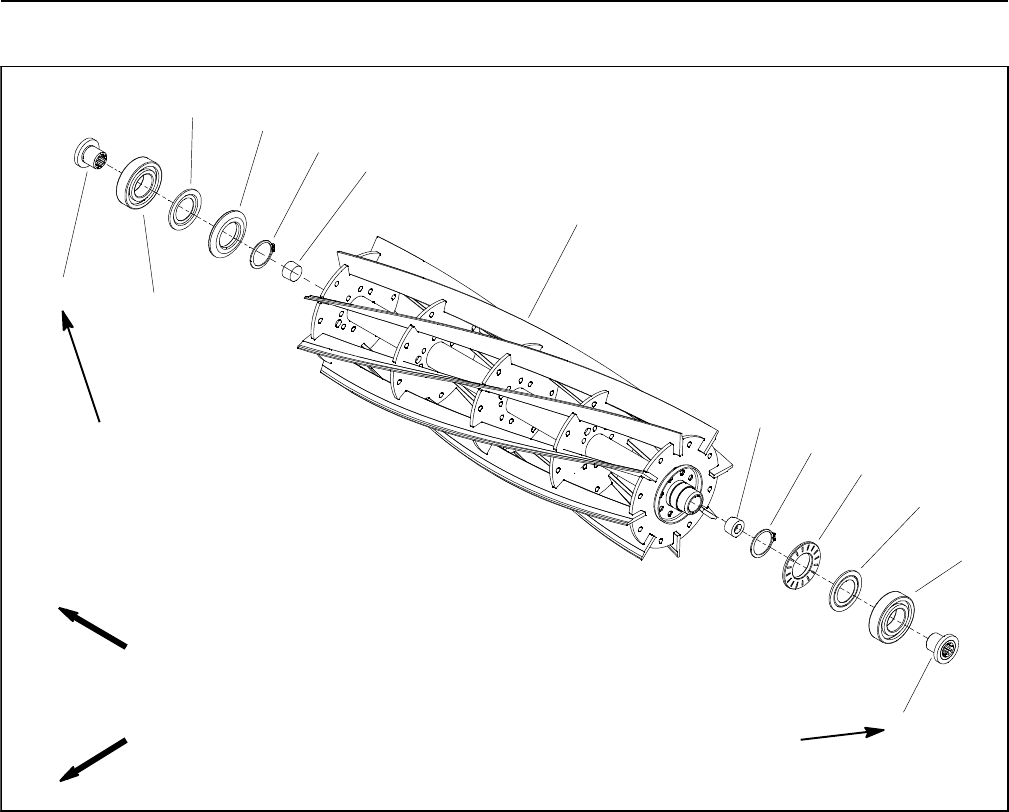

Cutting Reel Assembly Service

1. Cutting reel

2. Threaded insert (RH thread)

3. Bearing

4. Flocked seal

5. Special washer

6. Retaining ring

7. Reel shaft plug

8. Threaded insert (LH thread)

Figure 31

85 to 95 ft-lb

(115 to 128 N-m)

85 to 95 ft- lb

(115 to 128 N-m)

Loctite #242

Loctite #242

3

2

6

5

4

1

FRONT

RIGHT

(Right Hand Threads)

(Left Hand Threads)

7

8

3

4

7

6

5

Disassembly of Cutting Reel (F ig. 31)

1. Remove threaded inserts (items 2 and 8) from cut-

ting reel.The threaded insert withthe grooveontheface

has LH threads and is in end of reel shaft identified with

a groove that is just inside of reel spider (Fig. 32). Use

correct spline insert tool for insert removal (see Special

Tools in this chapter).

2. Slide bearings (item 3) from reel shaft.

3. Note orientation of flocked seals (item 4) for assem-

bly purposes (flocked (red) side orientated toward bear-

ing location). Remove flocked seals from reel shaft.

4. Note orientation of special washers (item 5) for as-

sembly purposes (flat side toward bearing location).

Carefully drive special washers from reel shaft.

5. If necessary, remove reel shaft plugs (item 7) from

reel shaft.

6. Discard removed components and replace during

cutting reel assembly.

Inspection of Cutting Reel (Fig. 31)

1. Check the threaded inserts for excessive wear or

distortion. Replace inserts if damage is evident.

2. Inspect thereel shaft asfollows.If reeldamageis de-

tected, replace reel.

A. Check the reel shaft for bending and distortion by

placing the shaft ends in V- blocks.

B. Check the reel blades for bending or cracking.

C. Check the service limit of the reel diameter (see

Preparing a Reel for Grinding in this section).