Reelmaster 5010- HPage 5 - 62Electrical System

Toro Electronic Controller (TEC)

Reelmaster 5010- H machines use a Toro Electronic

Controller (TEC) to control electrical system operation.

The TEC controller senses the condition of various

switches (inputs) and directs power output to allow cer-

tain machine functions. The TEC is attached to the con-

trol arm behind the access panel on the outside of the

control arm (Fig. 57).

Logic power is provided to the controller as long as the

battery cables are connected to the battery. A 2 Amp

fuse (fuse F4) provides circuit protection for this logic

power to the controller.

Inputs from the ignition, neutral, parking brake, reel en-

gage/disengage, seat, mow/transport, joystick lower/

raise, reels down limit, engine speed, engine

temperature sender and engine oil pressure switches

are all monitored by the TEC controller.

Current output to the lift circuit hydraulic valve solenoid

coils, engine components (glow plug relay, start r elay,

fuel pump andfuel actuator)and reelcircuit 48 VDC log-

ic relay are controlled based on the inputs received by

the TEC controller. Circuit protection for TEC outputs is

provided by three (3) 7.5 Amp fuses (fuse locations

F2- 1, F2- 2 and F2- 3).

The InfoCenter Display should be used when checking

inputsand outputs ofthe TECused on your Reelmaster.

If the TEC detects a malfunction in any of the controlled

circuits,the InfoCenterDisplayc an alsobe usedto iden-

tify the fault (see InfoCenter Display in this chapter).

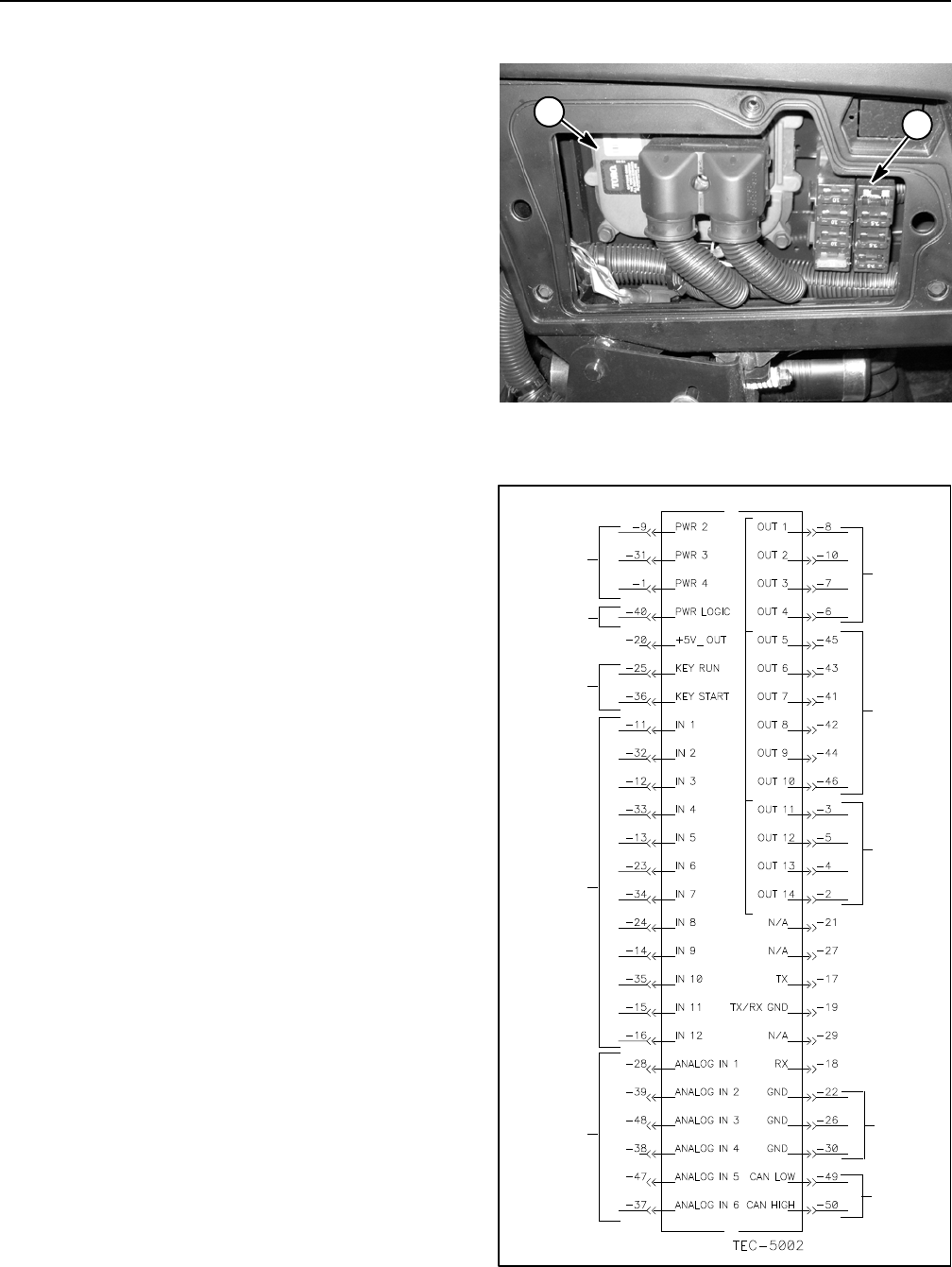

The diagram in Figure 58 depicts the connection termi-

nal functions for the TEC controller. Note that electrical

powerforcontrolleroutputsisprovidedthrough three(3)

connections (PWR 2, PWR 3 and PWR 4) each pro-

tected with a 7.5 amp fuse. A fifty (50) pin wire harness

connector attaches tothe controller.The connector pins

are identified in the diagram in Figure 58. The layout of

the wire harness connector that plugs into the TEC con-

troller is shown in Fig. 59.

IMPORTANT: When testing for wire harness con-

tinuity at the connector for the TEC controller, take

care to not damage the connector pins with multi-

meter test leads. If connector pins are enlarged or

damaged during testing, connector repair will be

necessary for proper machine operation.

The machine electrical schematic and wire harness

drawingsin Chapter 10 - Foldout Drawings canbe used

to identify possible circuit problems between the con-

troller and the input/output devices (e.g. switches and

solenoid coils).

1. TEC controller 2. Fuse block

Figure 57

1

2

Figure 58

12V POWER

(7.5AFUSES)

12VLOGIC

IGNITION

SWITCH

INPUTS

DIGITAL

INPUTS

(OPEN/

ANALOG

INPUTS

POWER

(2AMPFUSE)

CLOSED)

(VARIABLE)

CANBUS

OUTPUTS

(PWR2)

GROUND

OUTPUTS

(PWR3)

OUTPUTS

(PWR4)