Reelmaster 5010- HHydraulic System Page 4 - 6

Hydraulic Fitting Installation (SAE Straight Thread O- Ring Fitting into Component Port)

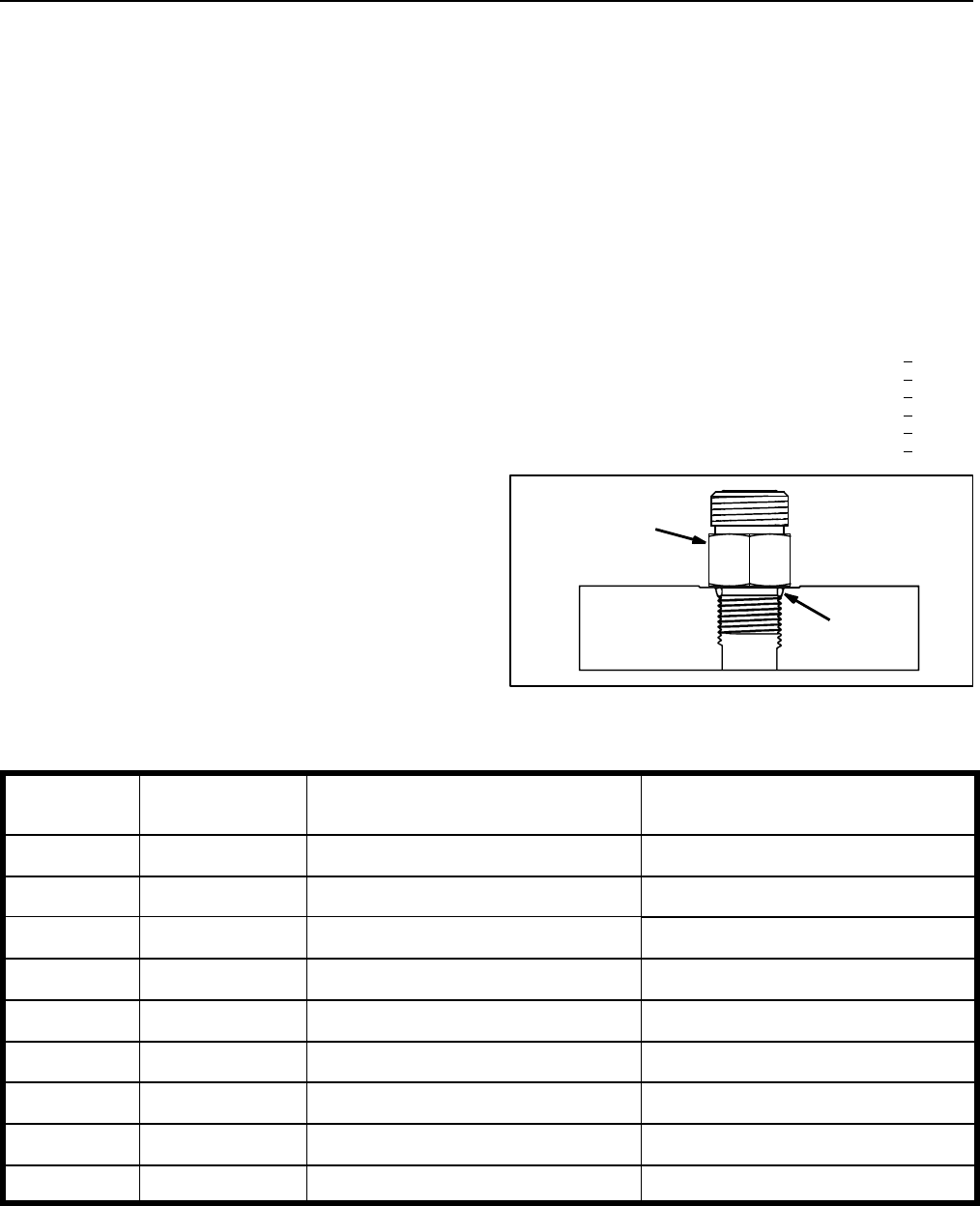

Non- Adjustable Fitting (Fig. 7)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it is rec-

ommended that the O- ring be replaced any time the

connection is opened.

3. Lightly lubricate the O- ring with clean hydraulic oil.

Fittingthreads shouldbeclean withnolubricant applied.

IMPORTANT: Before installing fitting into port, de-

termine port material. If fittingistobeinstalledinto

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recom-

mended inst allation torque shown in Figure 8.

NOTE: Useofanoffsetwrench(e.g.crowfootwrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

UsingaTorqueWrenchwithanOffsetWrenchinthe

Torque Specifications section of Chapter 2 - Product

Records and Maintenance todetermine necessarycon-

version information.

5. If a torque wrench is not available, or if space at the

port prevents useof a torquewrench, analternate meth-

od of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and t ighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T. If port material is aluminum, tighten f it-

ting to 60% of listed F.F.F.T.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

0.25

6 (3/8 in.) 1.50 +

0.25

8 (1/2 in.) 1.50 +

0.25

10 (5/8 in.) 1.50 +

0.25

12 (3/4 in.) 1.50 +

0.25

16 (1 in.) 1.50 +

0.25

Figure 7

O-ring

Fitting

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 - 20 15 to 19 ft- lb (21 to 25 N- m) 9to11ft-lb(13to15N-m)

5 1/2 - 20 18 to 22 ft- lb (25 to 29 N- m) 11 to 15 ft- lb (15 to 20 N- m)

6 9/16 - 18 34 to 42 ft- lb (47 to 56 N- m) 20 to 26 ft- lb (28 to 35 N- m)

8 3/4 - 16 58 to 72 ft- lb (79 to 97 N- m) 35 to 43 ft- lb (48 to 58 N- m)

10 7/8 - 14 99 to 121 ft- lb (135 to 164 N- m) 60 to 74 ft- lb (82 to 100 N- m)

12 11/16- 12 134to164ft-lb(182to222N-m) 81to99ft-lb(110to134N-m)

14 13/16- 12 160to196ft-lb(217to265N-m) 96 to 118 ft- lb (131 to 160 N- m)

16 15/16- 12 202to248ft-lb(274to336N-m) 121to149ft-lb(165to202N-m)

20 15/8- 12 247to303ft-lb(335to410N-m) 149to183ft-lb(202to248N-m)

Figure 8