Reelmaster 5010- H Page 5 - 3 Electrical System

Toro Electronic Controller (TEC)

Reelmaster 5010- H machines use a Toro Electronic

Controller (TEC) to manage machine electrical func-

tions. The controller is microprocessor controlled t hat

senses the condition of various switches and sensors

(inputs). The controller then directs electrical power to

control appropriate machine functions (outputs) based

on the input state. Communication between the TEC

controller,theInfoCenterDisplay,thecuttingunit motors

and the motor/generator is provided bya CAN- bus sys-

tem. The status of inputsto the TEC controller as well as

outputs from the TEC controller can be monitored with

the InfoCenter Display.

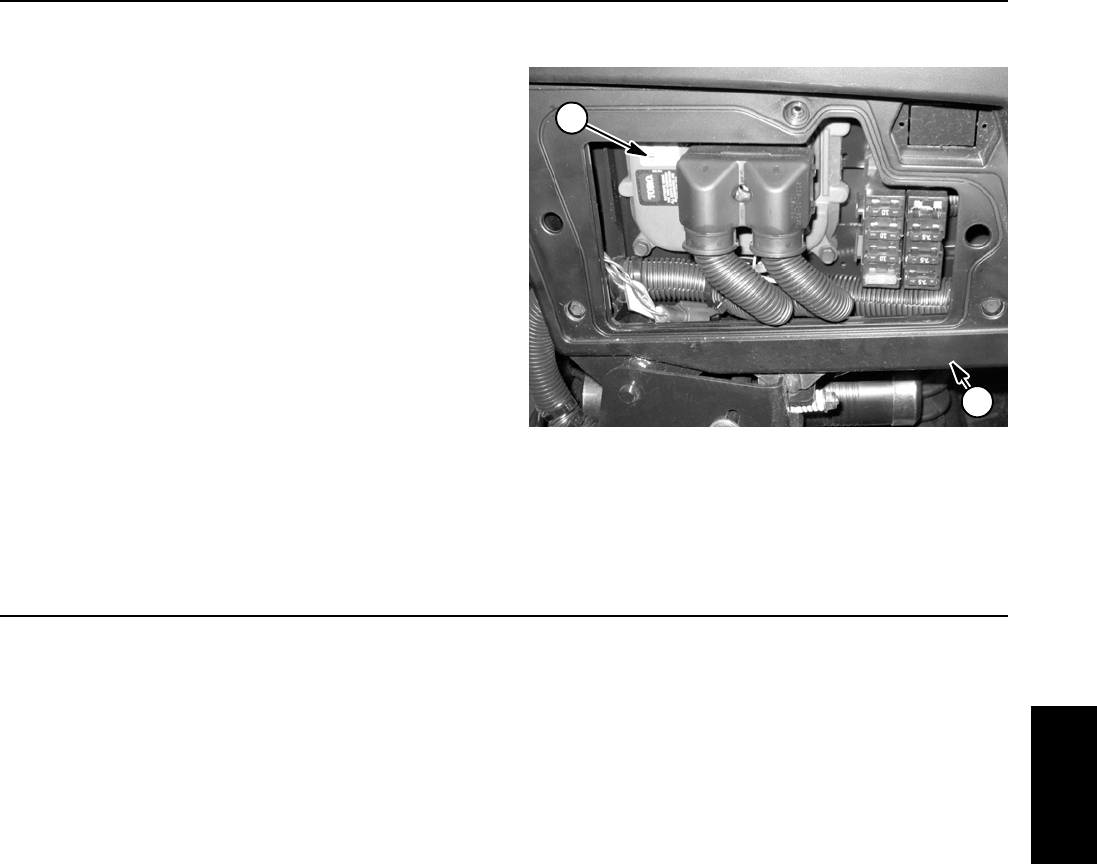

The TEC controller is located behind the access panel

on the outside of the control arm (Fig. 2).

IMPORTANT: To prevent machine electrical system

damage while welding on the machine, disconnect

thebatterycables fromthebatteries,disconnectthe

wire harness connectors from the Toro Electronic

Controller and disconnect the terminal connector

from the alternator.

1. Control arm 2. TEC controller

Figure 2

1

2

CAN- bus Communications

System communication between electrical components

on Reelmaster 5010- H machines is accomplished on

two (2) CAN- bus communication systems. These

CAN- bus systemsreduce thenumber of electricalcom-

ponents and connections used on the machine and al-

low the number of wires in the wire harness to be

reduced. The integration ofmachine electrical functions

also allows the InfoCenter Display to assist with electri-

cal system diagnostics.

One of these CAN- bus systems allows TEC controller

communication between machine 12 VDC components

(e.g. engine components, InfoCenter display). The sec-

ond CAN- bus system provides necessary control for

the electric cutting reels system (motor/generator, cut-

ting reel motors). An isolation module is included in the

machine electrical system to allow communication be-

tween the two systems while maintaining ground isola-

tion for the 48 VDC system.

CANidentifies theController Area Networks that isused

on the Reelmaster. Two (2) specially designed, twisted

wires form the bus for both of the networks used on the

Hybrid machines. These wires provide the data path-

ways between machine components. The engineering

term for these two (2) wires a re CAN- high and CAN-

low. At the ends of the twisted pair of bus wires are 120

ohm termination resistors. Thebus wiresfor the12 VDC

circuitsareblack/whiteandred/whiteandthebuswires

for the 48 VDC circuits are green and yellow.

Each of the components that is controlled by the CAN-

buslinkneedsonlyfour(4)wirestooperateandcommu-

nicate to the system: CAN High, CAN Low, B+ (power)

and ground. TheCAN- bus needsthe ignition switchON

input for the TEC, InfoCenter Display, motor/generator

and cutting unit motors to be activated.

IMPORTANT: The termination resistors at the ends

of the bus wires are required for proper electrical

system operation.

Electrical

System