Reelmaster 5010- H Hydraulic SystemPage 4 - 35

5. Start engine and run at idle speed. Check for any hy-

draulic leakage from test connections and correct be-

fore proceeding with test.

6. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine under load for

approximately ten (10) minutes.

7. Make sure that traction pedal is in neutral, the steer-

ing wheel is stationary and parking brake is engaged.

8. Increase engine speed to high idle speed (3000

RPM) and monitor pressure gauge to determine no load

charge pressure. Record test results.

GAUGE READING TO BE approximately 200 to

250 PSI (13.8 to 17.2 bar)

9. Next, determine charge pressureunder tractionload

by operatingthemachinein adirectforwardand reverse

direction (not steering). Make sure that engine is run-

ning at full speed (3000 RPM). Apply the brakes and

pressthe tractionpedal inthef orward directionand then

to reverse while monitoring the pressure gauge. Stop

engine and record test results.

GAUGE READING TO BE approximately 150 to

250 PSI (13.8 to 17.2 bar)

10.Compare measured charge pressure from step 8

with pressure from step 9:

A. If charge pressure isgood under no load (step 8),

but drops below specification when under traction

load (step 9), the piston (traction) pump should be

suspected of wear and inefficiency. When the pump

is worn ordamaged, the chargesystem is not able to

replenish lost traction circuit oil due to excessive

leakage in the worn pump.

B. If there is no charge pressure, or pressure is low,

check for restrictionin gear pump intake line.Inspect

charge relief valve and valve seat in the piston (trac-

tion) pump (see Piston (Traction) Pump Service in

the Service and Repairs section of this chapter).

Also, consider a worn or damaged gear pump sec-

tion (P2) (see Gear Pump Flow Test in this section).

NOTE: If gear pump (P2) is worn or damaged, both

charge circuit and steering circuit will be affected.

11.After charge pressure testing is completed, make

sure that engine is not running and then relieve hydrau-

lic system pressure (See Relieving Hydraulic System

Pressure in the General Information section of this

chapter).Remove pressure gauge from test port and in-

stall dust cap to test port.

12.Lower and secure operator seat.

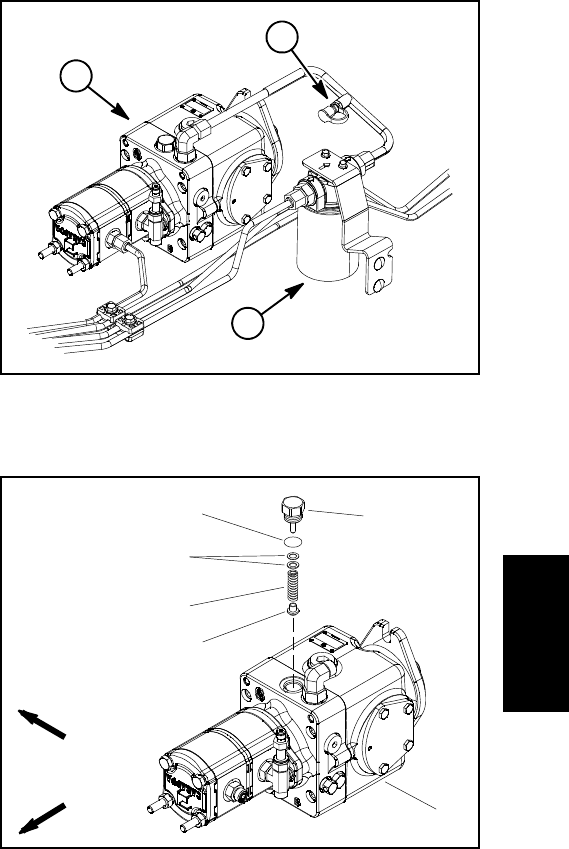

1. Piston (traction) pump

2. Oil filter

3. Test fitting

Figure 30

1

3

2

1. Piston (traction) pump

2. Plug

3. O-ring

4. Shim kit

5. Spring

6. Charge relief poppet

Figure 31

FRONT

RIGHT

2

3

4

1

5

6

Hydraulic

System