Reelmaster 5010- H Hydraulic SystemPage 4 - 99

3. Label all hydraulic connections f or assembly pur-

poses. Thoroughly clean hydraulic hose ends prior to

disconnecting hoses from the steering cylinder.

4. Disconnect hydraulic hoses from fittings in steering

cylinder.

5. Put capsor plugs ondisconnected hosesand fittings

to prevent contamination.

6. Remove two (2) jam nuts(item 11) that secure steer-

ing cylinder toaxle. Remove cotter pin(item 12),washer

(item 14)and slotted hex nut(item 13) that securesteer-

ing cylinder to RH drag link.

7. Separate ball joints from axle assembly and remove

steering cylinder from machine.

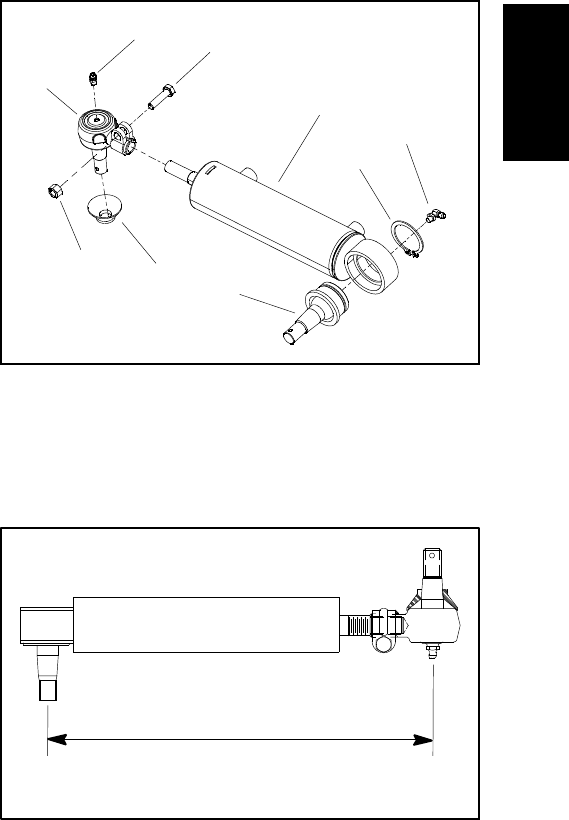

8. If necessary, remove ball joints from steering cylin-

derbarreland shaft(Fig. 82).Ifball jointisto beremoved

from cylinder shaft, fully retract cylinder shaft and mea-

sure center to center length to ease installation of ball

joint onto cylinder shaft (Fig. 83).

9. If hydraulic fittings are to be removed from steering

cylinder, mark fitting orientation to allow correct assem-

bly. Remove fittings from steering cylinder and discard

O-rings.

Installation (Fig. 81)

1. If hydraulicfittings wereremoved fromsteeringcylin-

der,lubricate new O- rings with clean hydraulic oil, posi-

tion O- rings to fittings and install fittings into steering

cylinder ports (see Hydraulic Fitting Installation in the

General Information section of this chapter). Make sure

that fittings are orientated correctly.

2. Ifremoved,pressball jointinto barrelandsecurewith

retaining ring. Make sure that retaining ring is fully seat-

ed in groove in steering cylinder barrel.

3. If ball joint was removed from cylinder shaft, fully re-

tract cylindershaft andthread balljointonto shaftso that

center to center length is as measured during removal

process. Tighten clamp bolt and nut.

4. Thoroughly clean tapers on ball joints and axle as-

sembly.

5. Position steering cylinder to machine.

6. Secure steering cylinder to axle with jam nuts (item

11). Tighten firstjam nut andthen, whileholding first jam

nut with wrench, tighten second jam nut.

7. Secure steering cylinder to RH drag link with washer

(item 14) and slotted hex nut (item 13). Install cotter pin

(item 12).

8. Remove caps and plugs from hydraulic hoses and

fittings.

9. Lubricate and install new O- rings on steering cylin-

der fittings. Correctly connect hydraulic hoses to steer-

ing cylinder fittings (see Hydraulic Hose and Tube

Installation in the General Information section of this

chapter).

10.Check oil level in hydraulic reservoir and add correct

oil if necessary.

11.Lubricate cylinder ball joint grease fittings.

12.Follow Hydraulic System Start- up procedures (see

Hydraulic System Start- up in this section).

13.Check that steering cylinder does not contact the

axle or frame as cylinder moves from fully retracted to

fully e xtended. Also, check that distance between the

drag links and steering stops are equal on both sides of

the machine. If necessary, adjust location of ball joint on

cylinder shaft.

1. Steering cylinder

2. Ball joint

3. Retaining ring

4. Grease fitting

5. Ball joint

6. Hex nut

7. Cap screw

8. Seal

9. Grease fitting

Figure 82

1

2

3

4

5

6

7

8

9

Figure 83

MEASURE CENTER TO CENTER LENGTH

FOR ASSEMBLY PURPOSES

Hydraulic

System