Reelmaster 5010- H Hydraulic SystemPage 4 - 33

NOTE: If machine is equipped with optional

CrossTrax

TM

AWD, reverse relief pressure test ports

are located on CrossTrax

TM

hydraulic manifold.

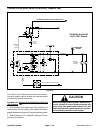

3. Thoroughly clean traction circuit test port on hydrau-

lic tube for direction to be checked (Fig. 27). Connect a

5000 PSI (350 bar) pressure gauge to test port.

4. After installing tester, start engine and run a t low idle

speed. Check for any hydraulic leakage from t est con-

nections and correct before proceeding with test.

5. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine under load for

approximately ten (10) minutes.

6. Sit on seat and increase engine speed to high idle

speed (3000 RPM).

7. Apply brakes and slowly depress the traction pedal

in the direction to be tested (forward or reverse). While

pushing traction pedal down, carefully watch the pres-

sure gauge needle. As the traction relief valve lifts, the

gauge needle will momentarily stop. Traction system

pressure as the relief valve opens should be:

Approximately3625 PSI(250 bar)inboth forward

(R3) and reverse (R4)

NOTE: If traction pedal continues to be pressed after

the relief valve has opened, system pressure may in-

crease higher than relief pressure.

8. When relief pressure has been identified, release

traction pedal, stop engine and record test results.

NOTE: Forward (R3) and reverse (R4) relief valves are

identical. Relief valves can be switched in piston (trac-

tion)pumptohelpinidentifyingafaultyreliefvalve.

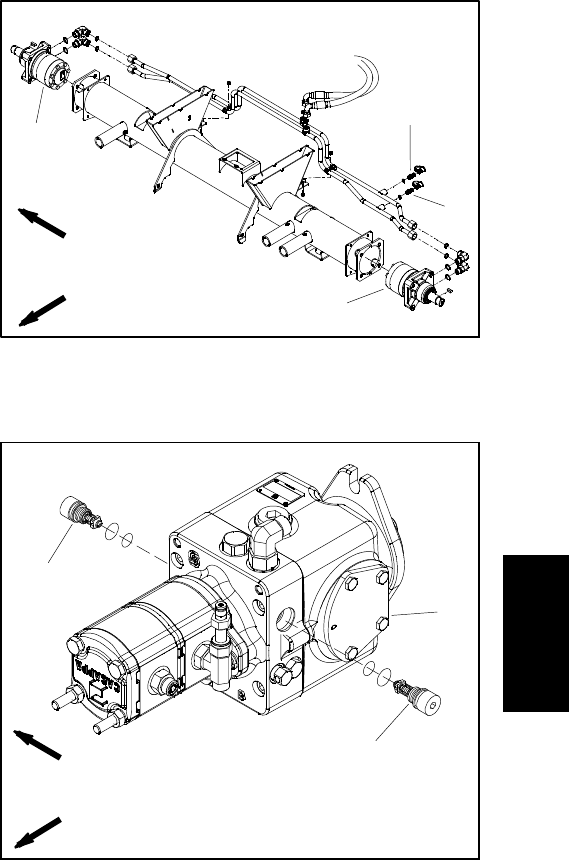

9. If traction pressure problem occurs in one direction

only, interchange the relief valves in the piston (traction)

pump(Fig. 28)to seeifthe problemchangesto theother

direction. Clean or replace valves as necessary. These

cartridge type valves are factory set, and are not adjust-

able.If tractionreliefpressure islow andreliefvalves are

in good condition, piston (traction) pump and/or wheel

motors should be suspected of wear and inefficiency.

10.After testing is completed, make sure that engine is

stopped and then relieve hydraulic system pressure

(See Relieving Hydraulic System Pressure in the Gen-

eral Information section of this chapter). Remove pres-

sure gauge from machine and install dust cap to test

port.

1. RHwheel motor

2. LH wheel motor

3. Forward test port

4. Reverse test port

Figure 27

FRONT

RIGHT

2WD MACHINE SHOWN

2

3

4

1

1. Piston (traction) pump

2. Reverse relief valve (R4)

3. Forward relief valve (R3)

Figure 28

2

3

1

FRONT

RIGHT

Hydraulic

System