Reelmaster 5010- HPage 5 - 92Electrical System

Motor/Generator Assembly

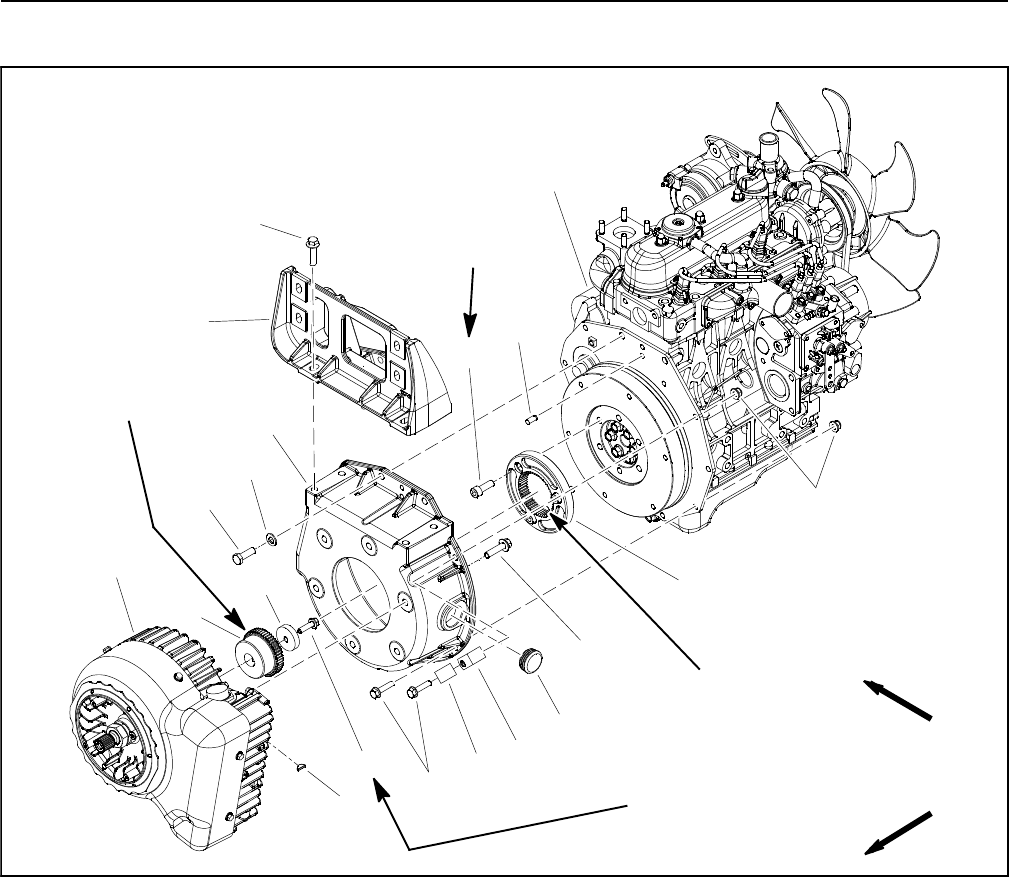

Figure 97

1. Diesel engine

2. Motor/generator assembly

3. Flange head screw

4. Collar

5. Coupler hub

6. Woodruff key

7. Engine bellhousing

8. Cap screw (2 used)

9. Flat washer (2 used)

10. Flange head screw (7 used)

11. Flange nut (2 used)

12. R-clamp (for generator wire harness)

13. Clamp (for fuel return hose)

14. Caplug

15. Flange head screw (6 used)

16. Dowel pin (2 used)

17. Coupler flange

18. Socket head screw (3 used)

19. Muffler bracket

20. Flange head screw (4 used)

3

9

10

11

5

4

13

2

6

8

1

7

12

14

15

16

17

18

19

20

FRONT

RIGHT

50 to 60 ft- lb

(68to81N-m)

25 to 31 ft-lb

(34to42N-m)

Antiseize

Lubricant

Antiseize

Lubricant

NOTE: If electrical problems exist with the motor/gen-

erator assembly, afaultshouldhaveoccurredthat would

be indicated by a fault code on the InfoCenter Display.

Before considering that motor/generator service work is

necessary, check for any existing fault codes that indi-

cate problems with the motor/generator (see Fault

Codes in the Troubleshooting section of this chapter).

NOTE: The 48 VDC motor/generator is secured to the

engine bellhousing with six (6) flange head screws. Ac-

cess to these screws requires the bellhousing and mo-

tor/generator to be removed from the engine as an

assemblybeforeremovingthemotor/generatorfromthe

bellhousing.

Removal (Fig. 97)

1. Park machine on a level surface, lower cutting units,

stop engine, apply parking brake and remove key from

ignition switch.

2. Separate system components from the 48 VDC bat-

tery pack by unplugging the 48 VDC battery disconnect.

(see48 VDCBatteryDisconnect intheGeneralInforma-

tion section of this chapter). This will prevent unex-

pected 48 VDC system component operation.

3. Raise and support hood and operator seat.