Reelmaster 5010- H Page 5 - 93 Electrical System

4. Disconnect hydraulic pump drive shaft from 48 VDC

motor/generator o utput shaft (see Hydraulic Pump

Drive Shaft in the Service and Repairs section of Chap-

ter4 - HydraulicSystem). Positiondriveshaft awayfrom

engine.

5. Remove exhaustmufflerfrommachine (seeExhaust

System in the Service and Repairs section of Chapter 3

- Kubota Diesel Engine).

6. Disconnect wire harness connector from motor/gen-

erator assembly.

CAUTION

Support motor/generator and bellhousing as-

sembly when removing it to prevent it from fal-

ling and causing personal injury. Assembly

weighs approximately 69 pounds (31 kg).

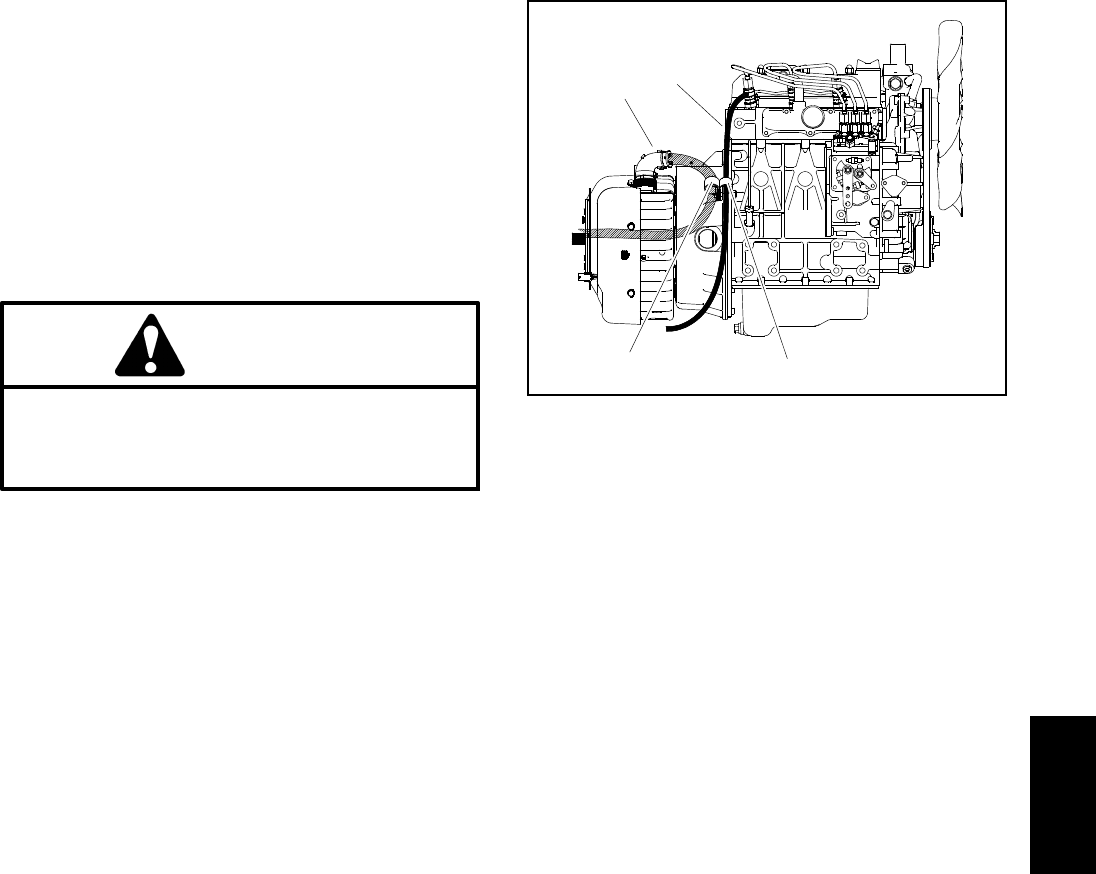

7. For assembly purposes, note locations of r- clamps

on bellhousing (Fig. 98). Support motor/generator and

bellhousingto prevent the assembly from falling or shift-

ing.

8. Remove fasteners that secure bellhousing to engine

plate. Position r- clamps with wire harness and fuel re-

turn hose away from bellhousing.

IMPORTANT: Make sure to not damage the motor/

generator,fuellines, hydraulichoses, electricalhar-

ness, control cables or o ther parts while removing

the motor/generator and bellhousing assembly.

9. Carefully move motor/generator and bellhousing as-

sembly away from engine so that motor/generator cou-

pler hub (item 5) slides out of flywheel coupler flange

(item 17). Once motor/generator coupler is removed

from flange, lift motor/generator and bellhousing as-

sembly from machine.

10.Note location of two (2) dowel pins (item 16) in en-

gine plate for assembly purposes.

11.Remove six (6) flange head screws that secure mo-

tor/generator to bellhousing. Remove motor/generator

from bellhousing.

12.If necessary, remove flange head screw and spacer

that secure motor/generator coupler hub to motor/gen-

erator input shaft. Use suitable puller to remove coupler

hub from motor/generator shaft. Locate and retrieve

woodruff key from motor/generator shaft.

1. Generator connector

2. R-clamp

3. Fuel return hose

4. R-clamp

Figure 98

3

2

1

4

Installation (Fig. 97)

1. If removed,install coupler hub tomotor/generator in-

put shaft:

IMPORTANT: Before coupler hub is installed to

motor/generator input shaft, thoroughly clean

tapers of coupler hub and motor/generator input

shaft.Make surethat tapersare freeof grease,oil

and dirt. DO NOT use antiseize lubricant when

installing coupler hub.

A. Thoroughly clean tapers on motor/generator in-

put shaft and coupler h ub bore.

B. Place woodruff key in motor/generator shaft slot

and then install the coupler hub onto the shaft.

C. Secure couplerhub to motor/generator shaft with

collar and flange head screw. Torque screw from 25

to 31 ft- lb (34 to 42 N-m).

2. Position motor/generator to bellhousing and secure

with six (6) flange head screws. Torque screws from 50

to 60 ft- lb (68 to 81 N-m).

3. Apply antiseize lubricantto splines of coupler hub on

motor/generator shaft and coupler flange on flywheel.

4. Make sure that dowel pins (item 16) are properly po-

sitioned in bellhousing.

Electrical

System