Reelmaster 5010- H

Cutting Units

Page 7 - 28

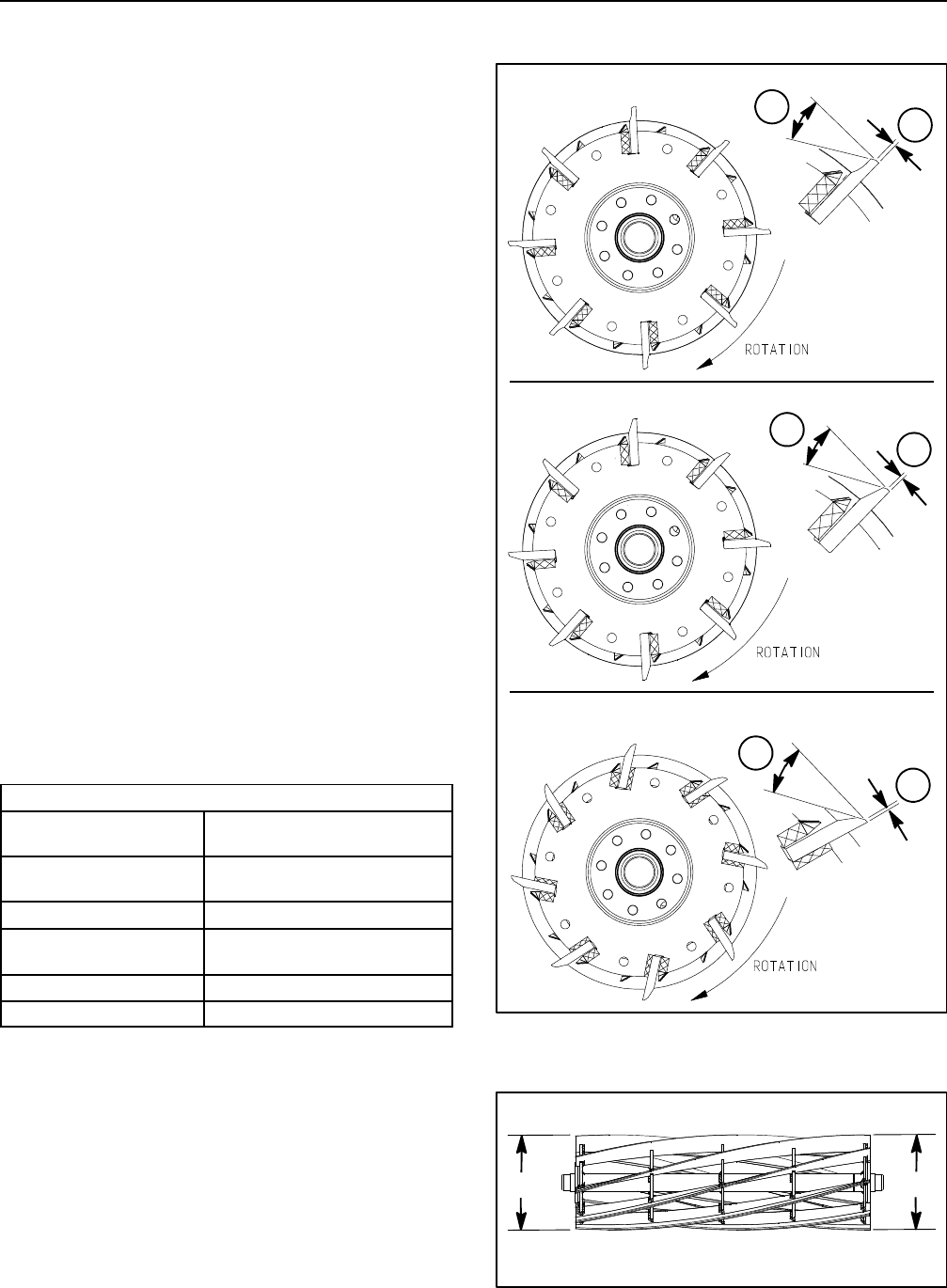

Preparing Reel for Grinding

Three(3)typesofcutting reeldesignsareusedincutting

units for Reelmaster 5010- H machines: scalloped radi-

al reel, tapered radial reel and tapered forward swept

reel. The different types of individual reel blades are

shown in Figure 34. The radial reel designs have blades

that are placed in line with the center of the reel shaft.

The rear of the blades either have a scalloped relief or

atapered relief.The forwardswept reelhave bladesthat

havea slightforwardslant.The rearofthe forwardswept

reel blades have a tapered relief.

Before grinding a reel, make sure to identify the type of

reel design to make sure that grinding is correctly done.

NOTE: Beforegrinding acutting reel,make surethat all

cutting unit components are in good condition. Depend-

ing on type of grinder used, faulty cutting unit compo-

nents can affect grinding results.

NOTE: When grinding, be careful to not overheat the

cutting reel blades. Remove small amounts of material

with each pass of the grinder.

Follow reel grinder manufacturer’s instructions to grind

cutting reel to Toro specifications (see Reel Grinding

Specifications chart below). Additional reel grinding in-

formation can be found in your Cutting Unit Operator’s

Manual and the Toro General Service Training Book,

Reel Mower Basics (part no. 09168SL).

After completing the reel grinding process, adjust cut-

ting unit (see Cutting Unit Operator’s Manual).

Reel Grinding Specifications

Reel Diameter (New) 5.060in(128.5mm)for5”reel

7.060in(179.3mm)for7”reel

Service Limit -

Reel Diameter

4.500 in (114 mm) for 5”reel

6.600 in (168 mm) for 7” reel

Reel Shaft Diameter (OD) 1.313in(33.3mm)

Service Limit -

Reel Diameter Taper

0.010 in (0.25 mm) for both

5” and 7” reel (Fig. 35)

BladeLandWidth 0.050 to 0.060 in (1.3 to 1.5 mm)

Blade Relief Angle 30

o

+/- 5

o

NOTE: Relief grind of cutting reel blades is necessary

when blade land width exceeds 0.120” (3 mm).

NOTE: After grinding the reel and/or bedknife, check

the reel to bedknife contact again after cutting two (2)

fairways. During this initial use, any burrs will be re-

movedfromreeland bedknifewhichmay createimprop-

er reel to bedknife clearance and thus accelerate wear.

This practice of re- checking the reel to bedknife contact

after grinding will extend the longevity of the sharpness

of the edge of the reel and the bedknife.

Figure 34

SCALLOPED RADIAL REEL

2

1

2

1

TAPERED RADIAL REEL

2

1

TAPERED FORWARD SWEPT REEL

1. Blade land width 2. Blade relief angle

Figure 35

D2

D1

Reel Diameter Taper = D1 - D2