Reelmaster 5010- HPage 5 - 8Electrical System

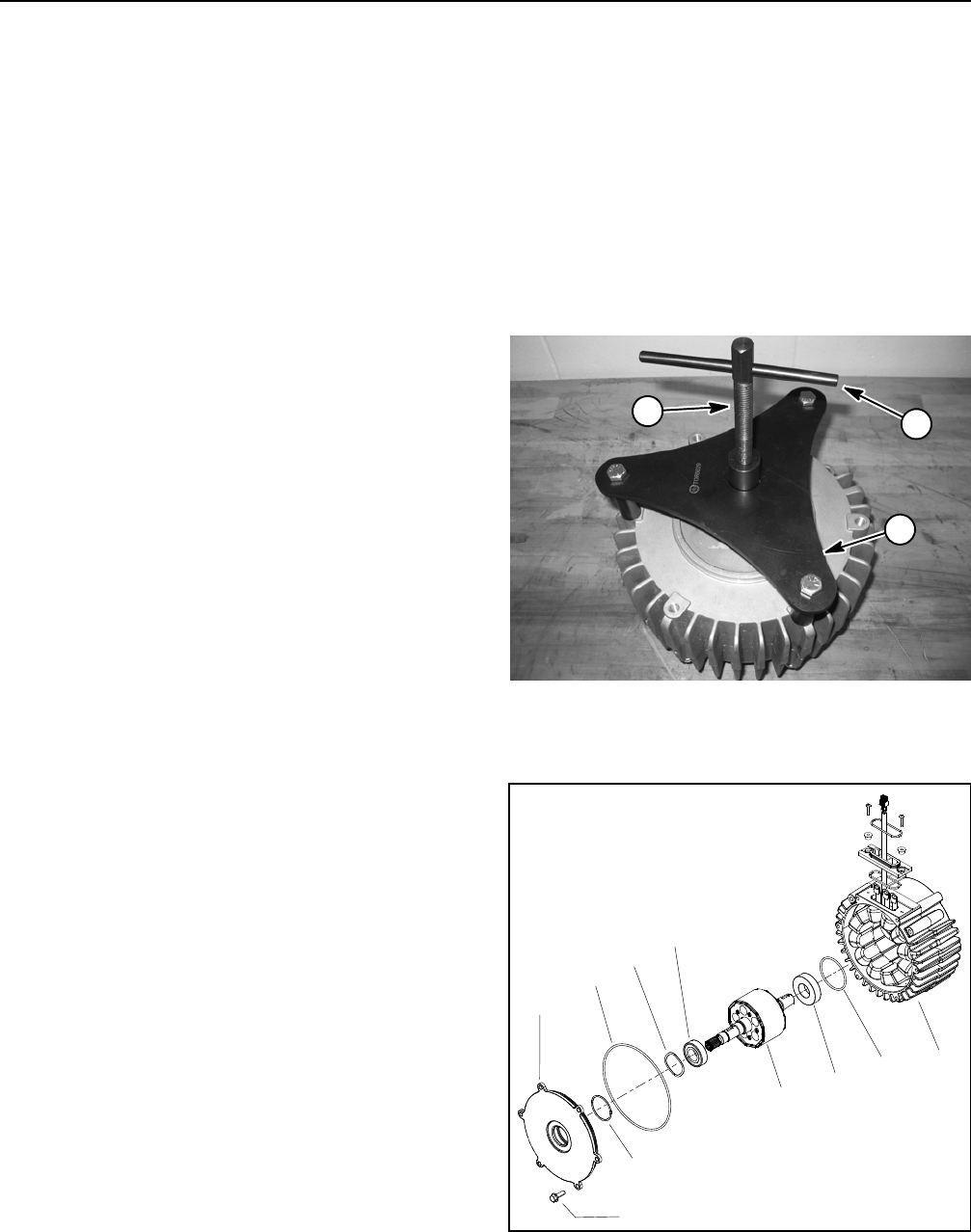

Generator Rotor Tool Set

Toro Part Number: TOR6029

The generator rotor tool set is required to remove and

install the rotor from the motor/generator housing. Tool

set includes base plate, threaded shaft and handle (Fig.

8).

NOTE: For motor/generator service procedures, see

Motor/Generator Assembly Service in the Service and

Repairs section of this chapter.

IMPORTANT: When working on the motor/genera-

tor, use a clean work space with a non- metal sur-

face. The motor/generator rotor includes very

powerful magnets.

Motor/Generator Rotor Removal (Fig. 9)

1. Remove screws that secure motor/generator cover.

Do not remove cover from motor/generator assembly

because it will be removed with motor/generator rotor

during rotor removal.

2. Secure tool set base plate to motor/generator hous-

ing with three (3) 3/8” - 16 X 3” cap screws.

IMPORTANT: To prevent damage to motor/genera-

tor rotor shaft threads, position a thick washer or

spaceron end ofthe rotorshaft whenusing tool set.

3. Position thick w asheror spacer onthe endof themo-

tor/generatorrotor shaft. Installthreaded shaftinto base

plate and against washer or spacer on rotor shaft.

IMPORTANT: The rotor magnets are very powerful

andcan causethe rotorto shiftposition veryrapidly

duringremoval.Be cautiousduring rotorremovalto

prevent component damage or personal injury.

4. Turn threaded shaft with handle to remove motor/

generator rotor and cover from motor/generator hous-

ing. Support rotor to prevent it from falling during

removal.

5. Leave threaded shaft installed in same position in

tool base plate for rotor installation purposes.

Motor/Generator Rotor Installation (Fig. 9)

1. Secure tool set base plate to motor/generator hous-

ing with three (3) 3/8” - 16 X 3” cap screws.

2. Make sure that threaded shaft is installed into tool

base plateso that theendofthethreaded shaft prevents

rotor body from entering the motor/generator housing.

IMPORTANT: The rotor magnets are very powerful

andcan causethe rotorto shiftposition veryrapidly

during installation. Be cautious during rotor instal-

lation topreventcomponent damageor personalin-

jury.

3. While guiding rotor into motor/generator housing,

slowly rotate threaded shaft to allow the r otor to be

drawn into the housing. Once rotor is fully installed into

housing, remove special tool set from motor/generator

housing.

1. Base plate

2. Threaded shaft

3. Handle

Figure 8

1

2

3

1. Housing/stator assembly

2. O-ring

3. Bearing

4. Rotor assembly

5. Bearing

6. Wave washer

7. O-ring

8. O-ring

9. Cover

10. Flange screw (6 used)

Figure 9

2

3

6

8

9

10

1

5

7

4