Reelmaster 7000Page 3 -- 14Kubota Diesel Engine

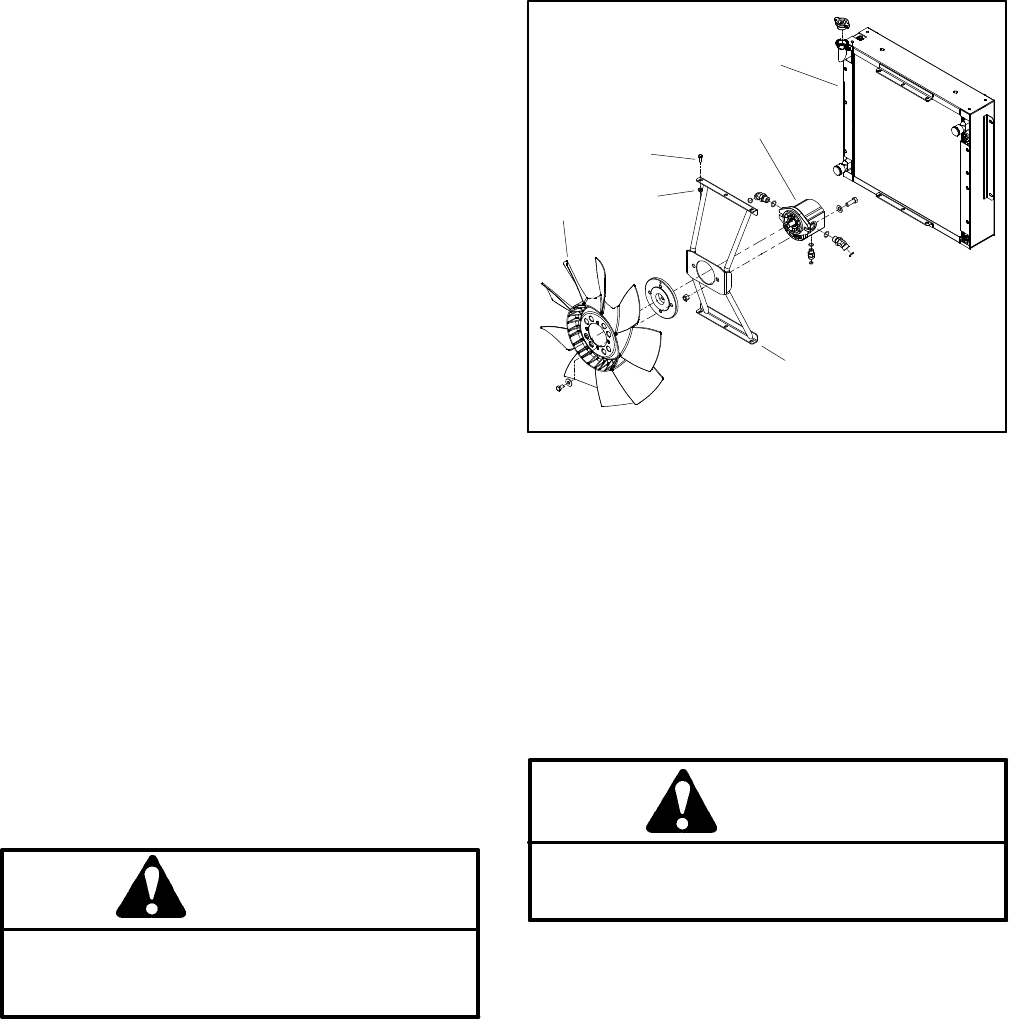

11.Remove fan motor and fan assembly (Fig. 11).

A. To prevent contamination of hydraulic system,

thoroughly clean exterior of fan motor and fittings.

B. Disconnect hydraulic hoses from cooling fan mo-

tor.Put capsor plugs onfittings andhoses to prevent

contamination. Label hydraulic lines for proper as-

sembly.

C. Remove six (6) cap screws and flange nuts that

secure fan motor bracket to radiator.

D. Carefullyremove fan motor,fanand motor brack-

et assembly from machine.

IMPORTANT: The hydraulic pumpassembly canre-

main in machine during engine removal. To prevent

pump assembly from shifting or falling, make sure

to support pump assembly before pump mounting

fasteners are removed.

12.Support hydraulic pump assembly. Remove fasten-

ers that secure piston (traction) pump assembly to en-

gine (see Piston (Traction) PumpAssembly Removalin

the Service and Repairs section of Chapter 4 -- Hydrau-

lic System).

13.Make sure all cable ties securing the wiring harness,

fuel lines or hydraulic hoses to the engine are removed.

14.Connect lift or hoist to the lift tabs on engine.

15.Remove flange nuts, rebound washers and cap

screws that secure the engine mount brackets to the

rubber engine mounts.

CAUTION

One person should operate lift or hoist while a

second person guides the engine out of the ma-

chine.

IMPORTANT: Make sure to not damage the engine,

fuel lines, hydraulic lines, electrical harness or oth-

er parts while removing the engine.

16.Carefully raise engine from the machine.

17.If necessary, removeengine mountsfrom theengine

using Figure 8 as a guide.

Engine Installation (Fig. 8)

1. Locate machineon a level surface with key removed

from the ignition switch. Chock wheels to keep the ma-

chine from moving.

Figure 11

1

2

3

4

5

6

1. Fan

2. Fan motor bracket

3. Fan motor

4. Cap screw (6 used)

5. Flange nut (6 used)

6. Radiator

2. Make sure that all parts removed from the engine

during maintenance orrebuilding are installedto the en-

gine.

3. Ifremoved, installengine mountsto theengineusing

Figure 8 as a guide.

4. Connect lift or hoist to the lift tabs on engine.

CAUTION

One person should operate lift or hoist while a

second person guides the engine into the ma-

chine.

IMPORTANT: Make sure to not damage the engine,

fuel lines, hydraulic lines, electrical harness or oth-

er parts while installing the engine.

5. Carefully lower engine into the machine.

6. Align engine to the rubber engine mounts and hy-

draulic pump input shaft. Secure engine to engine

mounts with cap screws, rebound washers and flange

nuts.

7. Securehydraulicpump assemblytoengine(seePis-

ton(Traction)PumpAssembly InstallationintheService

and Repairs section of Chapter 4 -- Hydraulic System).