Reelmaster 7000Hydraulic System Page 4 -- 94

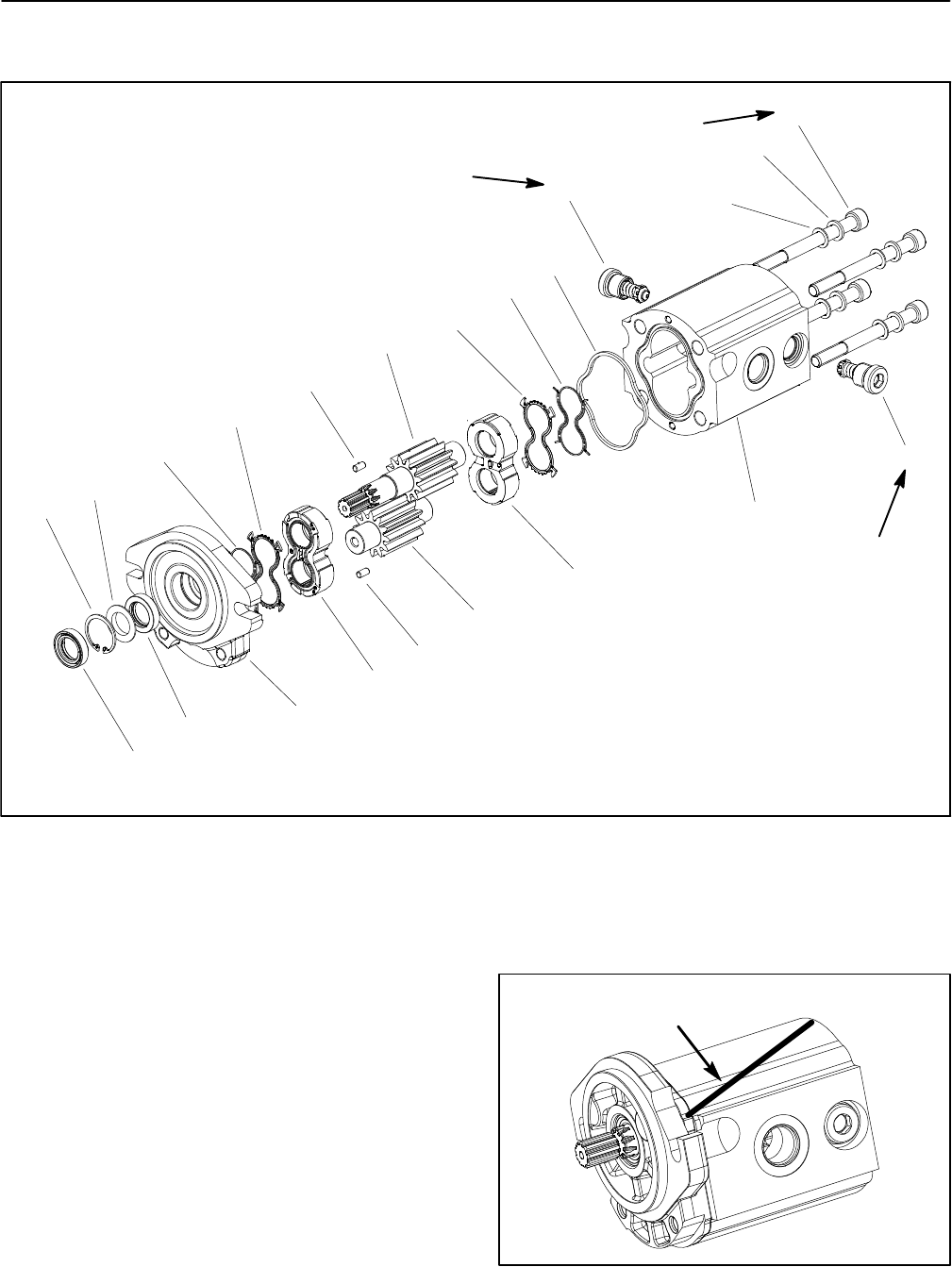

Cutting Reel Motor Service

1. Dust seal

2. Retaining ring

3. Flange washer

4. Shaft seal

5. Front flange

6. Pressure seal

7. Back--up gasket

8. Front wear plate

9. Dowel pin

10. Idler gear

11. Drive shaft

12. Rear wear plate

13. O--ring

14. Relief valve

15. Body

16. Washer (4 used)

17. Lock washer (4 used)

18. Cap screw (4 used)

2

3

6

9

9

10

11

13

1

5

7

12

14

15

16

17

18

4

6

7

8

14

33 ft--lb

(45 N--m)

19 ft--lb

(25 N--m)

19 ft--lb

(25 N--m)

Figure 68

Disassembly (Fig. 68)

1. Plug motor ports and clean the outside of the motor

thoroughly. After cleaning, remove plugs and drain any

oil out of the motor.

2. Use a marker to make a diagonal line across the

front flange and body for assembly purposes (Fig. 69).

IMPORTANT: Prevent damage when clamping the

reelmotorinto avise;clamp onthefront flangeonly.

Also, use a vise with soft jaws.

3. Clamp front flange of motor in a vise with soft jaws

with the shaft end down.

MARKER LINE

Figure 69