Reelmaster 7000Hydraulic System Page 4 -- 76

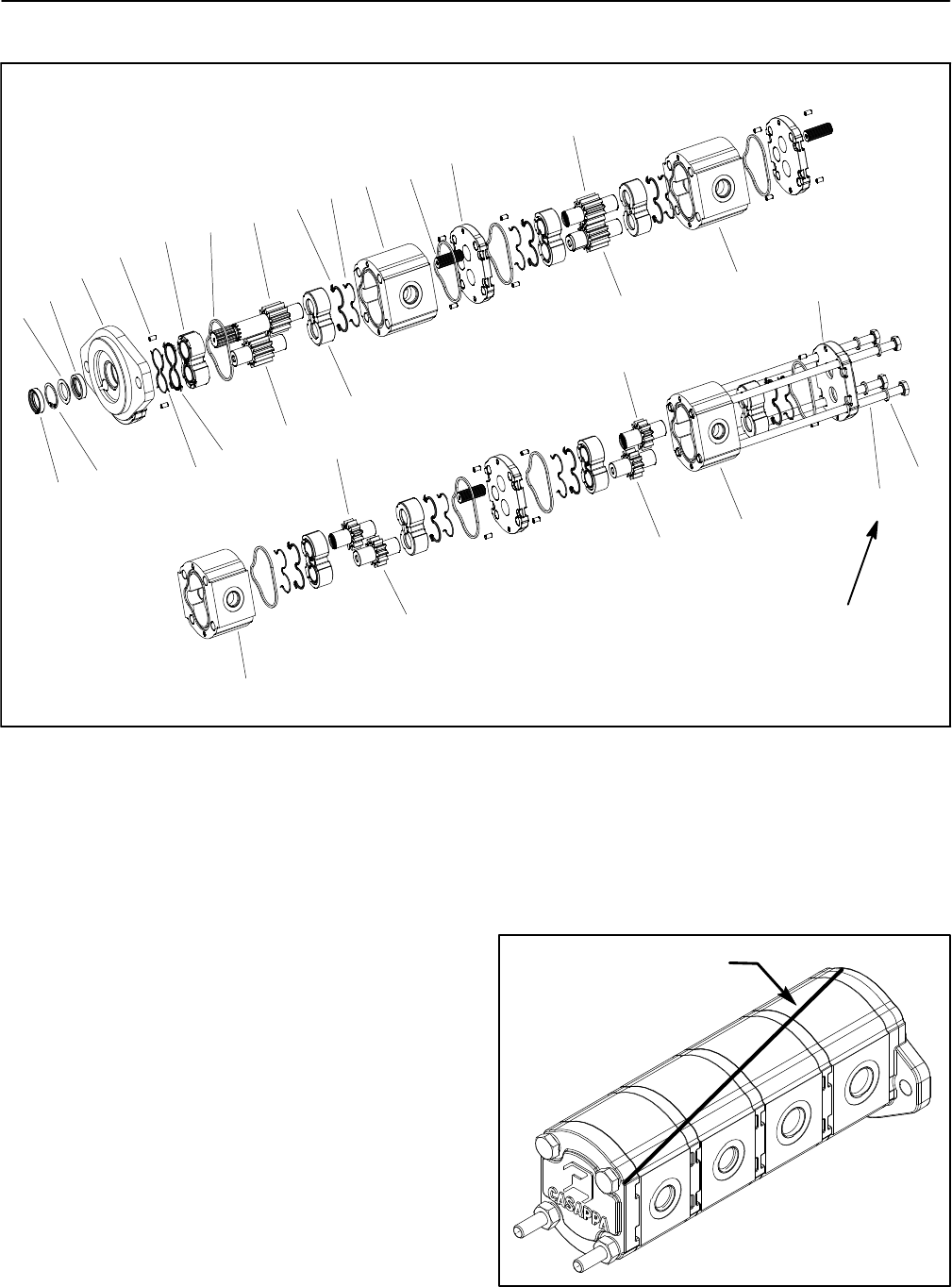

Gear Pump Service

1. Dust seal

2. Retaining ring

3. Flange washer

4. Shaft seal

5. Front cover

6. Dowel pin (16 used)

7. Pressure seal

8. Back--up gasket

9. Thrust plate (8 used)

10. Seal (8 used)

11. Idler gear

12. Drive shaft

13. Back--up gasket

14. Pressure seal

15. Front body (section P1)

16. Splined connecting shaft (3 used)

17. Flange

18. Drive gear

19. Body (section P2)

20. Body (section P3)

21. Drive gear

22. Idler gear

23. Rear body (section P4)

24. Rear cover

25. Cap screw (4 used)

26. Washer (4 used)

Figure 53

10

11

8

15

5

3

19

20

21

22

23

24

9

7

25

26

6

1

2

16

17

18

4

14

13

12

9

33 ft--lb

(45 N--m)

11

22

21

Disassembly (Fig. 53)

NOTE: Thegear pumpmustbe replacedas acomplete

assembly. Individual gears, housings and thrust plates

are not available separately. Disassemble gear pump

for cleaning, inspection and seal replacement only.

IMPORTANT: Keep bodies, gears, flanges and

thrustplates foreachpump sectiontogether;do not

mix parts between pump sections.

1. Plug pump ports and thoroughly clean exterior of

pump with cleaning solvent. Make sure work area is

clean.

2. Use a marker to make a diagonal line across the

gear pump for assembly purposes (Fig. 54).

Figure 54

DIAGONAL LINE