Reelmaster 7000 Page 6 -- 25 Axles, Planetaries and Brakes

5. Install a new stake washer. Install the lock nut finger

tight.

6. Setthebearingpreload bysecuringthe bearingcase

in a vise. Thread a M12 x 1.5 hex head cap screw into

the splined end of the input shaft/pinion gear andslowly

tighten the lock nut until 4 to 6 in-lb (0.4 to 0.7 N--m) of

force is required to rotate the input shaft/pinion gear in

the bearing case.

7. Secure the lock nut with the stake washer.

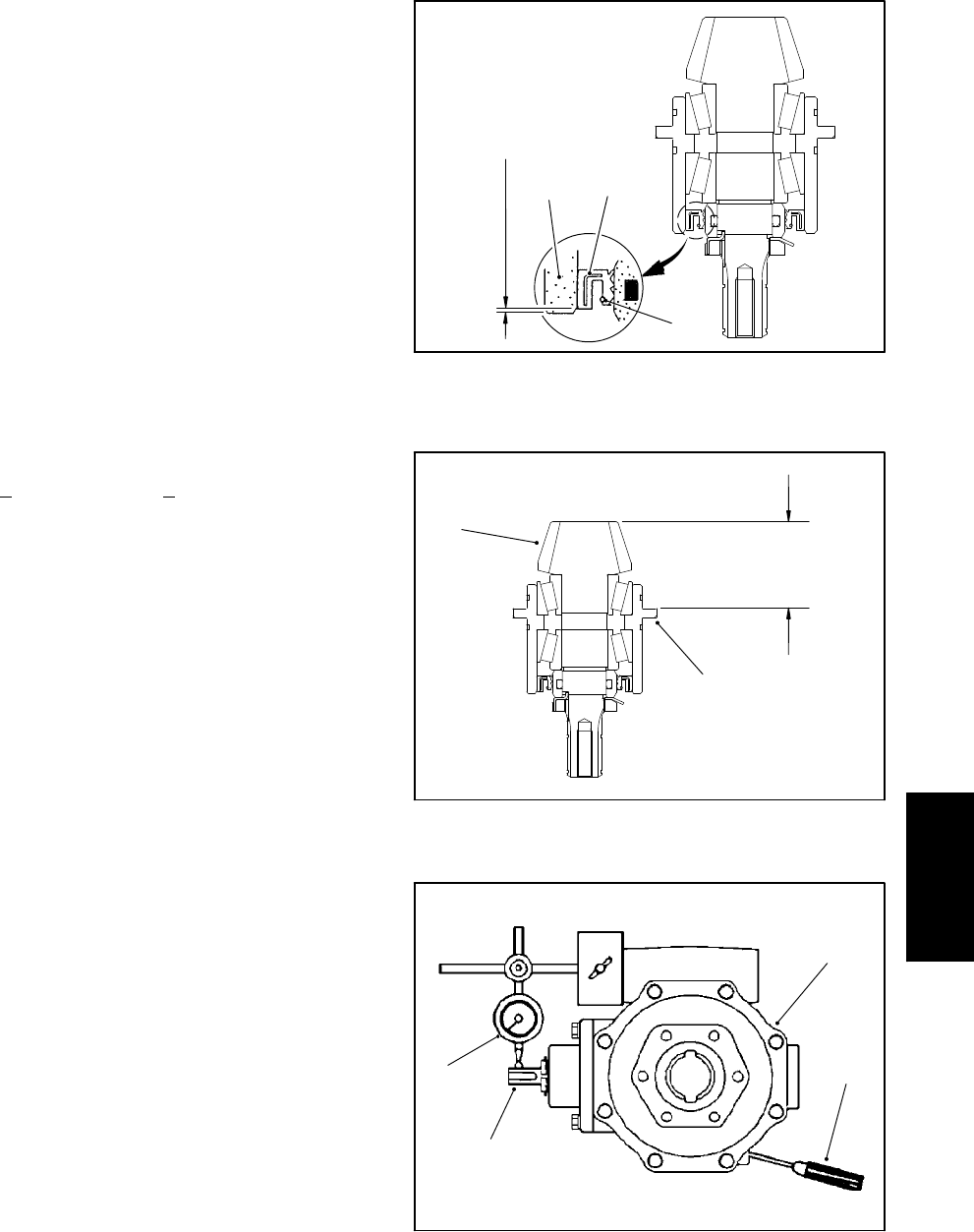

8. Use a depthgauge to measure the distance fromthe

end face of the input shaft/pinion gear to themating sur-

face of the bearing case. Subtract the “Design Cone

Center Distance” from this distance to determine initial

shim thickness (Fig. 30).

DESIGN CONE CENTER DISTANCE

(distance from mating surface of axle support to end

face of pinion gear):

1.870 +

0.002 inch (47.5 + 0.05 mm)

NOTE: Bearing case shims are available in 0.004 inch

(0.1 mm) and 0.008 inch (0.2 mm) thickness.

9. Coat newO-rings with grease and install the bearing

casein thegear case.Place shimson thegear case and

temporarily install gear case assembly into axle case.

Tighten mounting nuts and screws from 35 to 41 ft-lb

(47to56N--m).

10.Insert a screwdriver through the drain plug hole to

hold ring gear and measure the pinion gear to ring gear

backlash (Fig. 31).

PINION GEAR TO RING GEAR BACKLASH:

0.004 to 0.016 inch (0.10 to 0.40 mm)

11.Adjustbacklash by increasing or reducing gear case

shim thickness.

12.Check piniongeartoringgearengagement(seePin-

ion Gearto RingGear Engagement inthis sectionof this

manual).

13.Place the correct combination of shims on the gear

case. Tighten mounting nuts and screws from 35 to 41

ft-lb (47 to 56 N--m).

14.Install retaining rings and driven gear on input shaft/

pinion gear.

15.If thedrive gear (ondrive motor s haft) wasremoved,

install the retaining rings and drive gear on the motor

shaft.

16.Use a new gasket and install the cover plate. Use a

new O-ring and install the drive motor.

1. Oil seal

2. Bearing case

3. Seal garter spring

Figure 29

1

2

3

0.040 in. (1.0 mm)

1. Input shaft/pinion gear 2. Bearing case

Figure 30

1

2

Design

Cone Center

Distance

1. Axle case

2. Screwdriver

3. Dial indicator

4. Input shaft/pinion gear

Figure 31

1

2

3

4

Axles, Planetaries

and Brakes