Reelmaster 7000Hydraulic System Page 4 -- 74

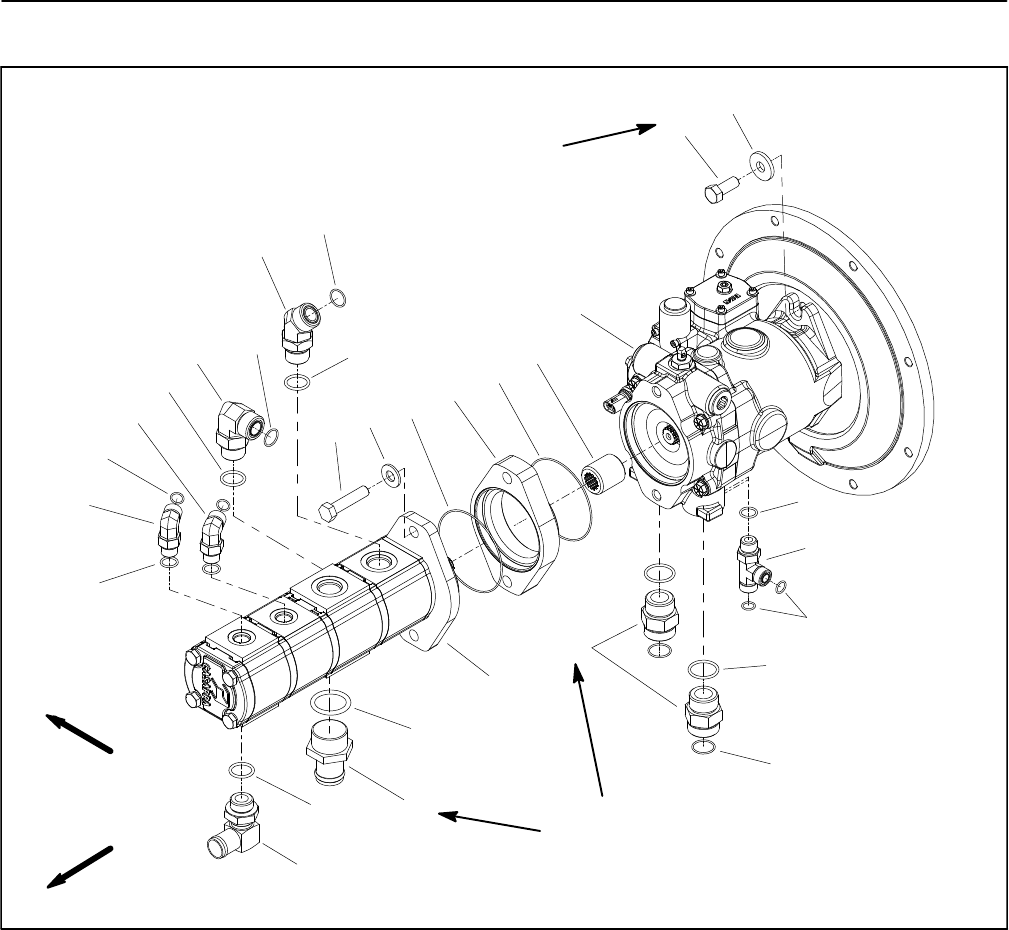

Gear Pump

1. Flat washer (2 used)

2. Cap screw (2 used)

3. 90

o

hydraulic fitting

4. Hydraulic tee fitting

5. O--ring

6. Gear pump assembly

7. Piston pump assembly

8. 90

o

hydraulic fitting

9. Coupler

10. 90

o

hydraulic fitting

11. O--ring

12. O--ring

13. 45

o

hydraulic fitting

14. Cap screw

15. Washer

16. O--ring

17. Spacer

18. O--ring

19. O--ring

20. Straight hose fitting

21. O--ring

22. Straight hydraulic fitting

23. O--ring

Figure 51

FRONT

RIGHT

1

2

3

4

23

16

6

12

8

9

10

13

5

21

11

18

17

20

19

14

15

22

7

5

11

11

12

8

16

18

77 to 93 ft--lb

(105 to 126 N--m)

103 to 118 ft--lb

(140 to 160 N--m)

Removal (Fig. 51)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Raiseseat and secure itwith prop rod to gainaccess

to gear pump.

3. Drain the hydraulic reservoir into a suitable contain-

er.

4. To prevent contamination ofhydraulic system during

removal, thoroughly clean exterior of pump and fittings.

5. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

6. Disconnect hydraulic lines from gear pump and put

caps or plugs on open hydraulic lines and fittings. Label

disconnected hydraulic lines for proper assembly (Fig.

52).