Reelmaster 7000Page 5 -- 32Electrical System

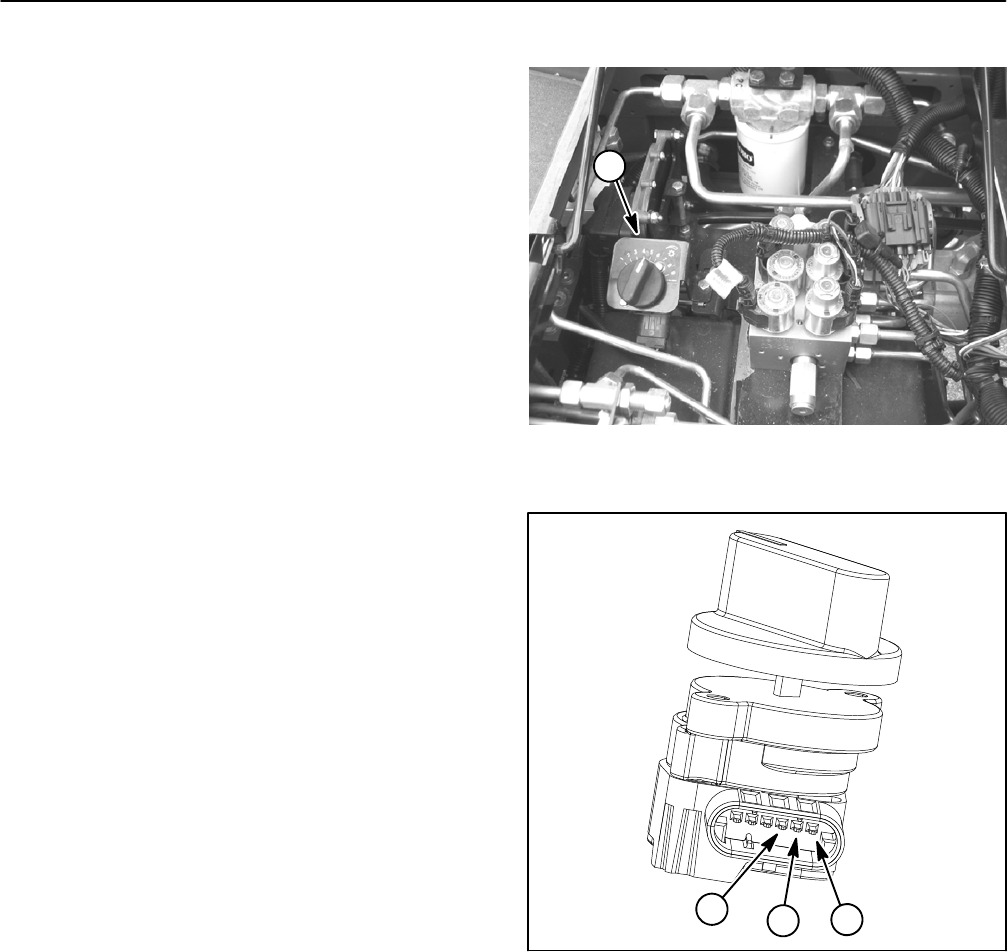

Reel Speed Potentiometer

The reel speed potentiometer controls the cutting reel

speed. The TEC controller uses the potentiometer set-

ting as aninput todetermine thenecessary voltageout-

put for the hydraulic mow control manifold proportional

valves(SP1 andSP2)forcorrect cuttingreelspeed. The

reel speed potentiometer is located under the operator

seat (Fig. 44).

Testing

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Raise and support operator seat to gain access to

reel speed potentiometer.

3. Carefully unplug wire harness connector from reel

speed potentiometer.

4. Remove screw that secures potentiometer to ma-

chine and remove potentiometer from machine for test-

ing.

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter andtest leads. Subtract this val-

ue from fromthe measured value of the componentyou

are testing.

5. Using a multimeter, measure resistances between

potentiometer terminals as follows (Fig. 45):

A. Verify that resistance between terminals B and C

is approximately 5000 ohms. Record measured re-

sistance.

B. Measure resistance between terminals A and C

and then measure resistance between terminals A

andB. Recordthese resistances.The totalof thetwo

measured resistances should be approximately

5000 ohms.

C. Rotate the reel speed potentiometerto other set-

tings and repeat step 6. The total of the two resist-

ances should consistently be approximately 5000

ohms.

D. If measured resistances are incorrect, replace

reel speed potentiometer.

6. After testing is completed, secure potentiometer to

machine frame. Secure wire harness connector to po-

tentiometer. Lower and secure seat.

1. Reel speed potentiometer

Figure 44

1

1. Terminal A

2. Terminal B

3. Terminal C

Figure 45

1

2

3