Reelmaster 7000 Hydraulic SystemPage 4 -- 83

Removal (Fig. 59)

NOTE: Theports onthe manifolds aremarked for easy

identification of components. Refer to the Hydraulic

Schematic in Chapter 9 -- Foldout Drawings to identify

the function of the hydraulic lines and cartridge valves

at each port.

1. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

2. To prevent contamination ofhydraulic system during

manifold removal,thoroughly clean exteriorof manifold.

3. If 4WD/2WD control manifold is being removed, la-

bel wire harness electrical connectors that attach to

manifold components. Disconnect harness electrical

connectors from the solenoid valve coil and electrical

sensors (pressure and temperature).

4. Disconnect hydraulic lines from manifold being re-

moved and put caps or plugs on open hydraulic lines

andfittings. Label disconnectedhydraulic lines forprop-

er assembly.

5. Remove hydraulic manifold from the frame using

Figure 59 as guide.

6. If hydraulic fittings are to be removed from control

manifold,mark fittingorientation toallow correctassem-

bly (Figure 60 or 61). Remove fittings from manifold and

discard O--rings.

Installation (Fig. 59)

1. If fittings were removed from control manifold, lubri-

cate and place new O--rings onto fittings. Install fittings

into manifold portsusing marks made duringthe remov-

al process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of this chapter). Refer to Figure 60 or 61

for fitting installation torque.

2. Install hydraulic manifold to the frame using Figure

59 as guide.

3. Remove caps and plugs from fittings and hoses.

Properly connect hydraulic lines to manifold (see Hy-

draulic Hose and Tube Installation in the General Infor-

mation section of this chapter).

4. If4WD/2WD controlmanifold wasremoved,connect

wire harness electrical connectors to the solenoid valve

coil and electrical sensors.

5. Check oil level in hydraulic reservoir and add correct

oil if necessary.

6. Follow Hydraulic System Start--up procedures (see

Hydraulic System Start--up in this section).

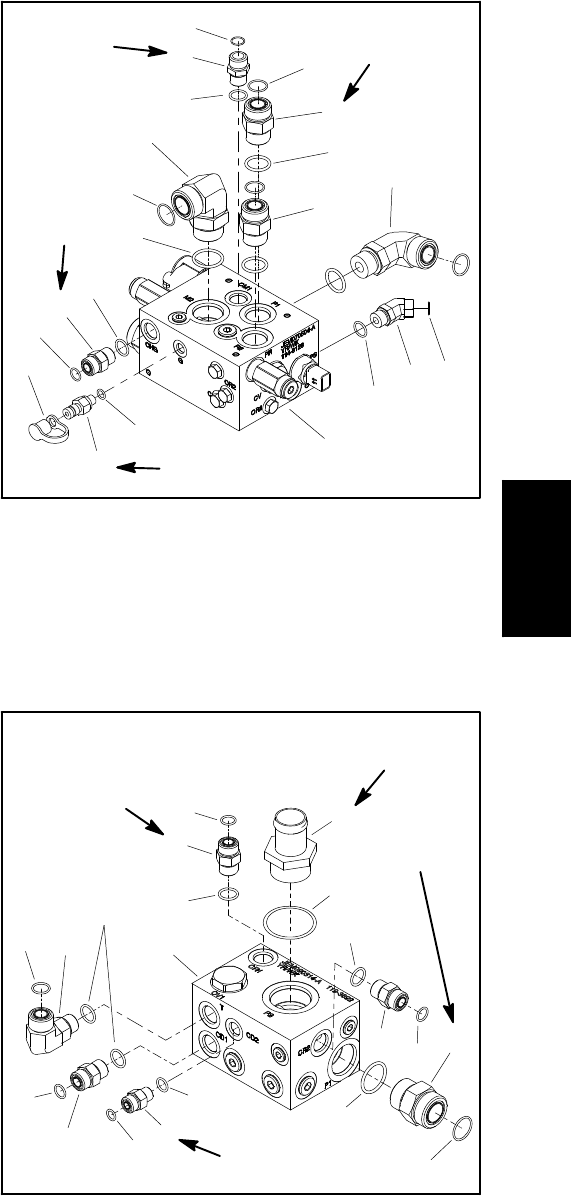

1. 4WD/2WD manifold

2. O--ring

3. 45

o

fitting

4. O--ring

5. 90

o

fitting

6. Straight fitting

7. O--ring

8. O--ring

9. Check fitting

10. O--ring

11. O--ring

12. Straight fitting

13. O--ring

14. Test fitting

15. Dust cap

Figure 60

4

2

6

5

7

3

1

8

9

2

2

4

4

5

6

10

12

11

13

14

15

50 ft--lb

(68 N--m)

75 ft--lb

(101 N--m)

25 ft--lb

(34 N--m)

20 ft--lb

(27 N--m)

1. Filtration manifold

2. O--ring

3. 90

o

fitting

4. O--ring

5. Straight fitting (3 used)

6. O--ring

7. Straight fitting

8. O--ring

9. O--ring

10. Straight fitting

11. O--ring

12. O--ring

13. Barb fitting

14. O--ring

Figure 61

75 ft--lb

(101 N--m)

2

3

6

8

9

10

11

13

1

5

7

12

14

4

2

5

5

6

6

25 ft--lb

(34 N--m)

50 ft--lb

(68 N--m)

2

75 ft--lb

(101 N--m)

Hydraulic

System