Reelmaster 7000Page 6 -- 6Axles, Planetaries and Brakes

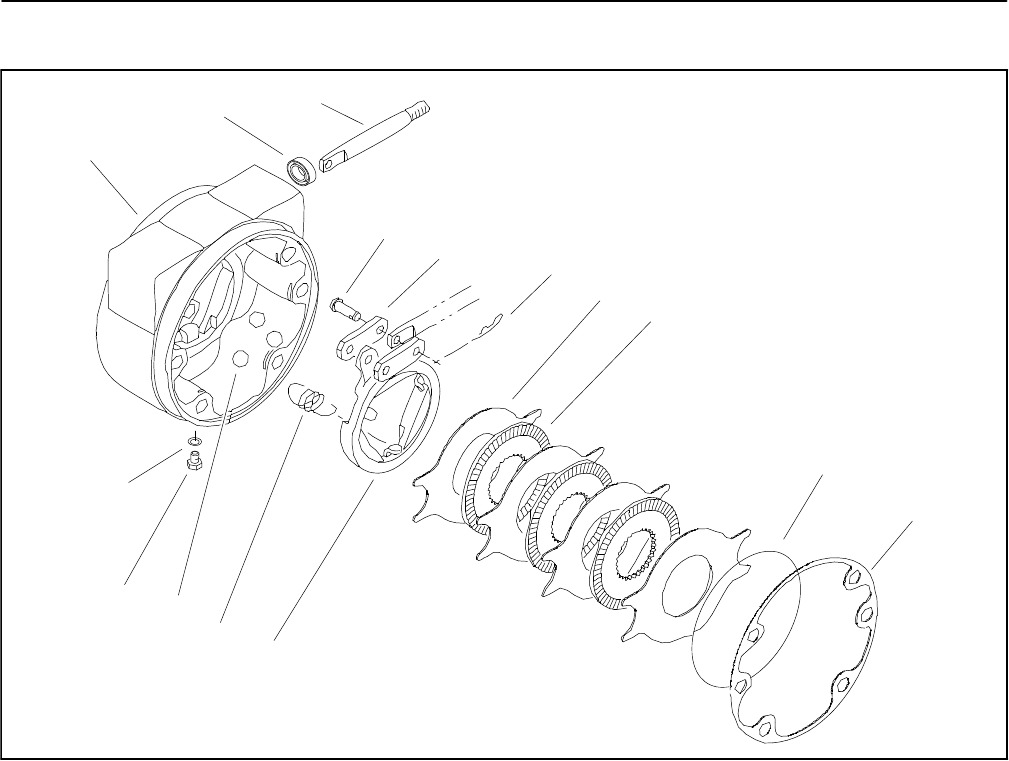

Brake Inspection and Repair

1. Brake housing (LH shown)

2. Seal

3. Pull rod

4. Clevis pin (2 used)

5. Link (2 used)

6. Hitch pin (2 used)

7. Stationary disc (4 used)

8. Rotating disc (3 used)

9. Retaining ring

10. Gasket

11. Rotating actuator

12. Extension spring (3 used)

13. Ball (3 used)

14. Plug

15. O--ring

Figure 4

3

2

4

5

6

7

8

9

10

14

13

12

11

15

1

Brake Inspection and Repair (Fig. 4)

1. Carefully scrape gasket material (item 10) from

brake housing and planetary wheel drive mounting sur-

faces.

2. Remove retaining ring (item 9).

3. Remove stationary discs (item 7) and rotating discs

(item 8).

4. Remove extension s prings (item 12).

5. Remove actuator assembly (items 3, 4, 5, 6 and 11)

and balls (item 13).

6. Remove seal (item 2) from brake housing.

7. Washparts in cleaningsolvent. Inspect components

for wear or damage.

8. Reverse steps 2 -- 6 to assemble brakes, installing

new parts as necessary. Install a new seal (item 2).

9. Usea newgasket (item10) wheninstalling brake as-

sembly to machine.