Reelmaster 7000 Hydraulic SystemPage 4 -- 101

Mow/Backlap Spool Service (Fig. 74)

1. To remove backlap spool (item 17) from mow man-

ifold:

A. Remove backlap switch (item 8) from mow man-

ifold before removing mow/backlap spool. Remove

dowel pin and ball from manifold port after switch is

removed. Remove and discard O--ring from switch.

B. Remove lower retaining ring from backlap spool.

Raise backlap spool to allow access to retaining ring

on upper end ofspool. Remove upper retaining ring.

C. Push spool down until O--ring and back--up ring

are exposed on bottom of mow manifold. Remove

lower O--ring and back--up ring from spool.

D. Pull spool up and out of mow manifold. Remove

O--rings and back--up ring from spool.

E. Discard removed O--rings and back--up rings.

2. To installbacklapspool(item17)from mowmanifold:

A. Install O--rings and back--up ring to upper

grooves on backlap spool. Apply a light coating of

grease to O--rings.

B. Carefully push backlap spool down into mow

manifold port until lower O--ring and back--up ring

groove is exposedon bottom of manifold.Install low-

er O--ring and back--up ring to s pool. Apply a light

coating of grease to O--ring.

C. Carefullyraisebacklapspooluntilupperretaining

ring groove on spool is exposed on top of manifold.

Install upper retaining ring.

D. Pushbacklapspooldown andinstalllowerretain-

ing ring to spool.

E. If handle was removed from spool, position spool

so handle location of spool is between stop pins in

manifold.Apply Loctite603 RetainingCompound (or

equivalent) to threads on handle and install handle

into spool.

F. Place ball and dowel pin in backlap switch man-

ifold port. Install new O--ring onto backlap switch.

Thread backlap switch into port and torque 20 ft--lb

(27 N--m).

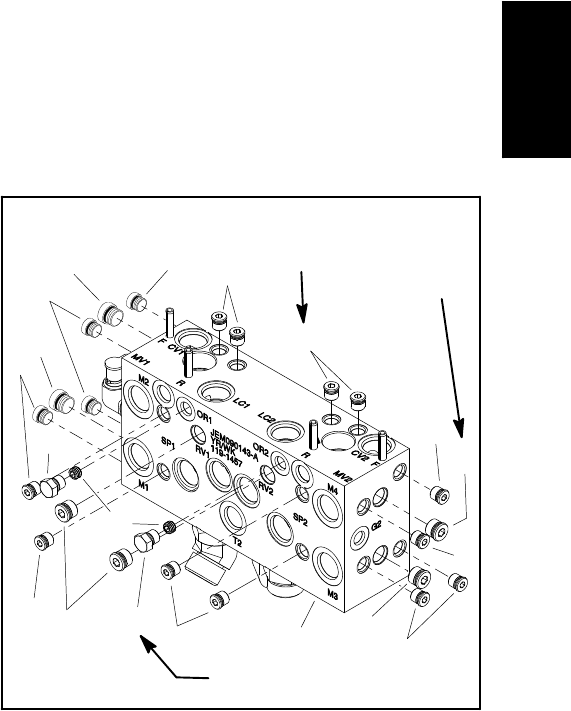

Manifold Plugs (Fig. 75)

NOTE: The mow control manifold uses several zero

leak plugs. These plugs have a tapered sealing surface

on the plug head that is designed to resist vibration in-

duced plug loosening. The zero leak plugs also havean

O--ring as a secondary seal. If zero leak plug removal is

necessary, lightly rap the plug head using a pin punch

andhammerbeforeusing anallenwrenchtoremovethe

plug:the impact willallow plugremoval with lesschance

of damage to the head of the plug.

IMPORTANT: An orifice is located beneath the plug

in mow control manifold ports OR1 and OR2. If an

orifice is removed from these manifold ports, make

sure to label its position for assembly purposes.

When installing the orifice in the manifold, make

sure thatthe orifice isproperly tightened inthe port.

1. RemoveplugsasneededusingFigure75asaguide.

Discard O--ring after plug removal.

2. Lubricate and place new O--ring onto removed

plugs.If plugwas removed fromport OR1or OR2,make

sure that orifice is correctly installed before threading

plug into manifold. Install plugs into manifold openings.

Torque#4 plugs to 20 ft--lb (27 N--m) and #6 plugs to 25

ft--lb (34 N--m).

1. Mow manifold

2. #4 zero leak plug

3. #6 zero leak plug

4. #4 zero leak plug

5. Orifice (.040)

Figure 75

1

2

3

4

5

2

2

2

2

2

2

2

2

3

3

3

3

4

2

20 ft--lb

(27 N--m)

25 ft--lb

(34 N--m)

20 ft--lb

(27 N--m)

Hydraulic

System