Reelmaster 7000

DPA Cutting Units

Page 8 -- 26

IMPORTANT: During cutting reel installation, keep

inner a nd outer bearing races aligned. If bearing

races are not aligned, binding will occur and reel

installation may cause bearing damage. Use reel

bearing installation tool (#117--0975) to help with

bearing alignment during reel installation.

3. Usingreelbearinginstallationtool(seeSpecialTools

in this chapter) to keep reel bearing aligned, carefully

slide thecutting reel withbearings and grease sealsinto

the RH side plate. Make sure that bearing is fully seated

into side plate.

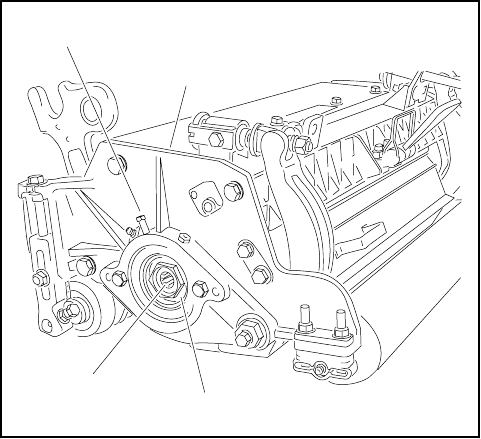

4. On LH side plate, loosen set screw and back--off

(loosen) bearing adjuster nut one complete turn (Fig.

31).

5. Usingreelbearinginstallationtool(seeSpecialTools

in this chapter) to keep reel bearing aligned, carefully

slide the LH side plate onto the cutting reel assembly,

front roller and rear roller. Make sure thatreel end inRH

side plate does not shift in position.

6. Install shoulder bolts (item 8) and flange nuts (item

24) that secure the LH side plate to the cutting unit

frame. Torque the shoulder bolts from 27to 33ft--lb (37

to 44 N --m).

7. Apply Loctite #242 (or equivalent) to threads of

flange head screw that secures support tube, frame

spacer and carrier frame to LH s ide plate (Fig. 30).

Install screw and torque from 27 to 33 ft--lb (37 to 44

N--m). After tightening screw, check the clearance be-

tween the carrier frame and side plate. If clearance is

more than 0.090” (2.3 mm), remove flange head screw

and position shim(s) (part number 67--9410) between

carrier frame and side plate so that clearance is less

than 0.090” (2.3 mm). Make sure that the carrier frame

pivots freely after assembly.

8. Install cap screw and flat washer that secure rear

grass shield to LH side plate (Fig. 30). Torque screw

from 15 to 19 ft-- lb (20 to 25 N--m).

9. Secure the bedbar assembly to LH side plate (see

Bedbar Installation in this section).

10.Secure front and rear rollers to LH side plate (see

Front Roller Installation and Rear Roller Installation in

this section).

IMPORTANT: After cutting unitassembly, reel bear-

ings must be adjusted properly or damage to reel

bearings will occur.

11.Adjust reel bearings (see Reel Bearing Adjustment

in the Set --up and Adjustments section of this chapter).

12.Adjust cutting unit (see Cutting Unit Operator’s

Manual).

NOTE: The parallel position of the rear roller to the cut-

ting reel is controlled by the precision machined frame

and side plates of the cutting unit. If necessary, the cut-

ting unit side plates can be loosened anda slight adjust-

ment can be made to parallel the rear roller with the

cutting reel (see Leveling Rear Roller in the Set--Up and

Adjustments section of this Chapter).

13.If cutting unit is equipped with optional rear roller

brush, install brush components to left hand side plate

of cutting unit. See Rear Roller Brush in this section for

information on rear roller brush.

14.If weight was removed from cutting unit, install new

O--ring(item 12)on weight.Secure weight tocutting unit

side plate with two (2) c ap screws. Torque screws from

27 to 33 ft--lb (37 to 44 N--m).

15.Lubricate cutting unit grease fittings until grease

purges from relief valves in side plates. Initial greasing

may require several pumps of a hand grease gun.

16.Install cutting unit to the machine (see Cutting Unit

Removal and Installation in this section).

1. LH side plate

2. Threaded insert

3. Bearing adjuster nut

4. Set screw

Figure 31

1

2

3

4