Reelmaster 7000

DPA Cutting Units

Page 8 -- 13

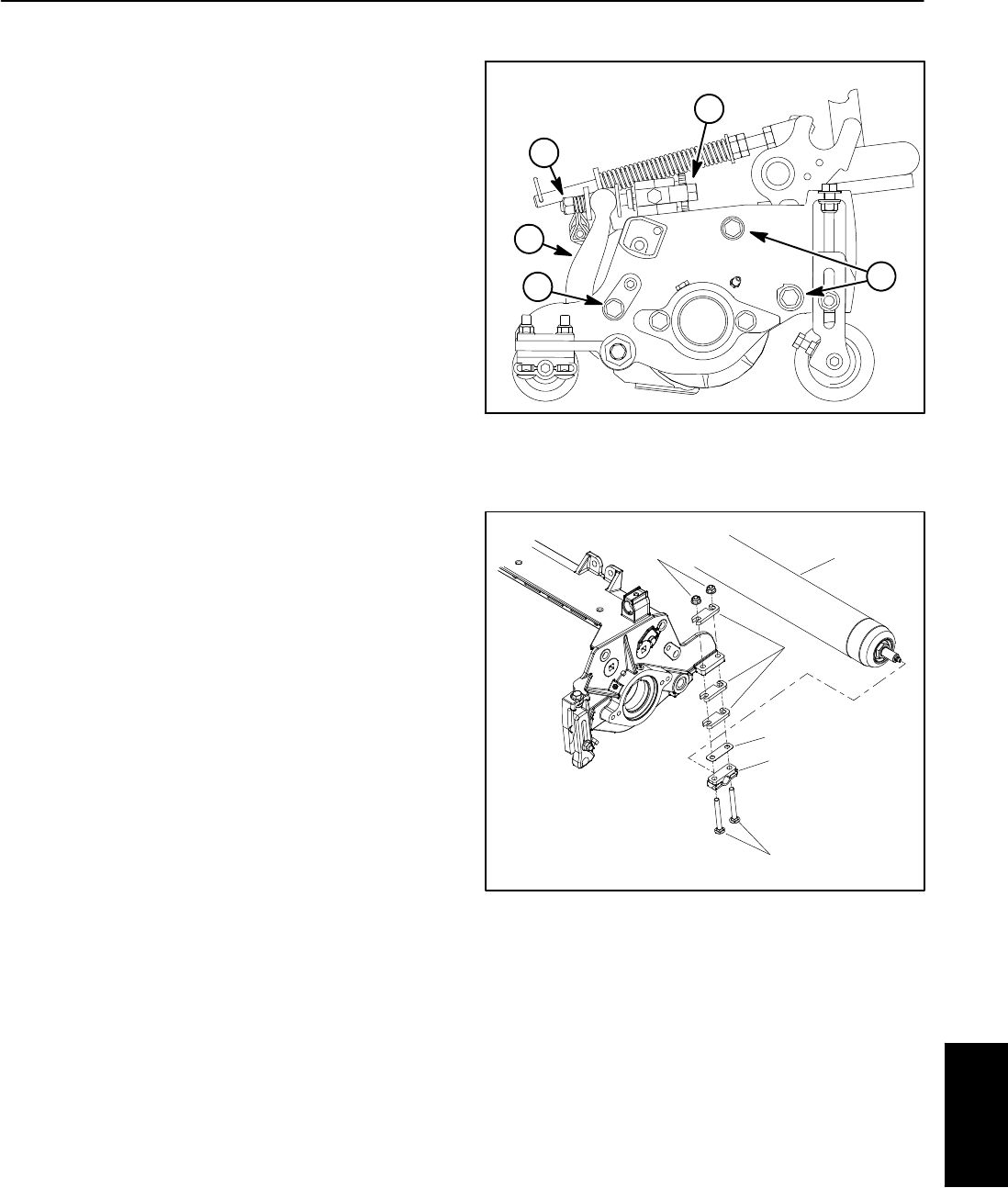

Leveling Rear Roller

The precision machined components of the cutting unit

frame keep the rear roller and cutting reel in alignment

(parallel). If the side plates are disassembled or as the

cutting reel wears, a limitedamount of side plateadjust-

ment is possible to make sure that the cutting unit is

properly aligned.

1. Place the assembled cutting unit on a surface plate.

2. Make sure that bedknife is properly adjusted to cut-

ting reel.

3. Using the surfaceplate, check if rear roller is level to

cutting reel by using a 0.005” (0.13 mm) shim at each

end of rear roller. If the shim will pass under the roller at

one end but not the other, a frame adjustment should be

made.

4. Loosen, but do not remove, the three (3) shoulder

bolts that securethe side plate to the frame oppositethe

side that is not level (Fig. 12).

5. Adjust the position of the side plate to parallel the

rear roller and cutting reel. Then, tighten the shoulder

bolts to a torque from 27 to 33 ft--lb (37 to 44 N--m).

6. Aftertighteningthe sideplate,recheck therearroller.

If necessary, loosen and adjust second side plate.

7. If rear roller is still not level after adjusting both side

plates, check to see if cutting reel is tapered (see Pre-

paring Reelfor Grinding in the Serviceand Repairs sec-

tionof this chapter).If cuttingreel is nottapered andrear

roller isnot level,a 0.010”shim (partnumber 107--4001)

is available to allow additional rear roller adjustment.

Use the shim on one side of the rear roller and install it

between the rear roller bracketand roller shim ( Fig. 13).

8. Afterleveling rearroller,complete cuttingunit set--up

and adjustment sequence.

1. Bedbar

2. Bedbar adjuster screw

3. Spring tension lock nut

4. Shoulder bolt

Figure 12

2

4

1

3

4

1. Rear roller assembly

2. Rear roller bracket

3. Carriage screw

4. Flange nut

5. Roller shim

6. 0.010” shim (if needed)

Figure 13

1

2

3

4

5

6

DPA Cutting

Units