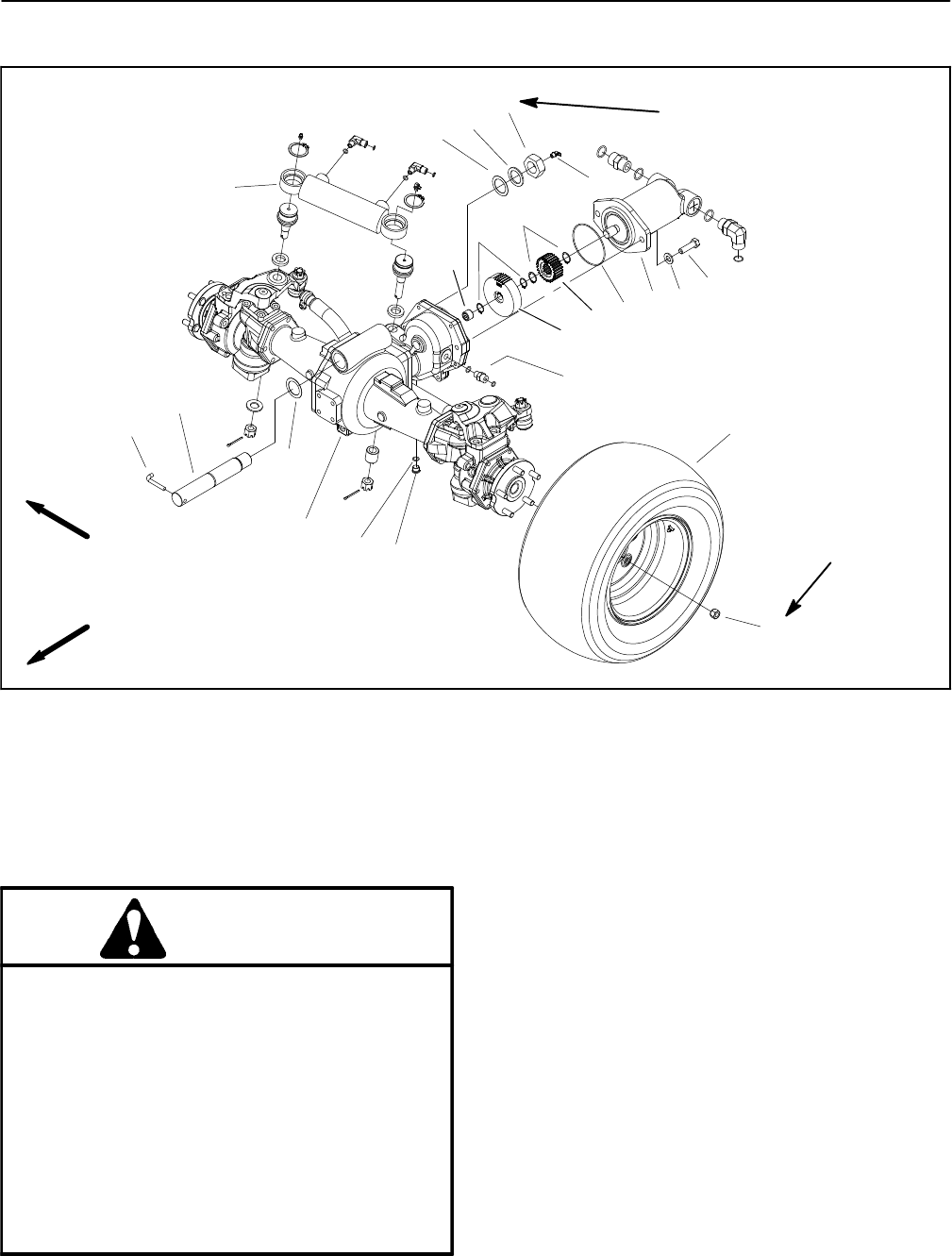

Reelmaster 7000Page 6 -- 14Axles, Planetaries and Brakes

Rear Axle Assembly

1. Steering cylinder

2. Needle bearing

3. External snap ring

4. External snap ring

5. Thrust washer

6. Flat washer

7. Lock nut

8. Grease fitting

9. Cap screw (2 used)

10. Flat washer (2 used)

11. Rear axle motor

12. O--ring

13. Pinion gear

14. Gear

15. Stop pin

16. Hydraulic fitting

17. Rear wheel assembly (2 used)

18. Lug nut (5 used per wheel)

19. Hex plug

20. O--ring

21. Drive axle assembly

22. Axle pivot pin

Figure 9

70 ft--lb (94 N--m) maximum

FRONT

RIGHT

1

2

3

13

4

14

12

9

10

11

17

21

20

19

18

22

5

6

8

7

16

15

85 to 100 ft--lb

(116 to 135 N--m)

5

CAUTION

When changing attachments, tires or perform-

ingother service,use correct blocks,hoists and

jacks to raise and support machine. Make sure

machine is parked on a solid level surface such

as a concrete floor. Prior to raising machine, re-

move any attachments that may interfere with

the safe and proper raising of the machine. Al-

ways chock or block wheels. Use appropriate

jack stands to supportthe raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

Remove Rear Axle (Fig. 9)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Drain oil from rear axle and axle gearbox.

3. Chockfront wheels and jack up rearof machine (see

JackingInstructions inChapter 1 -- Safety).Supportma-

chine with appropriate jack stands.

4. Remove both w heels from rear axle.

5. Remove hydraulic motor from axle assembly (see

Rear Axle Motor in the Service and Repairs section of

Chapter 4 -- Hydraulic System).

6. Remove hydraulic hoses from steering cylinder.