TP-6200 10/12150 Section 3 Scheduled Maintenance

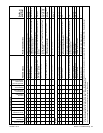

After reconnecting the battery cables, coat the terminals

with petroleum jelly, silicon grease, or other

nonconductive grease.

EZ-273000-J

1

2

12

12

1. To positive (+) terminal on starter solenoid.

2. To ground (--) terminal on or near starter motor.

Figure 3-16 12-Volt Engine Electrical System Single

Starter Motor Typical Battery Connection

1

1

1

11

2

2

2

2

2

1. To positive (+) terminal on starter solenoid.

2. To ground (--) terminal on or near starter motor.

Figure 3-17 24-Volt Engine Electrical System Single

Starter Motor Typical Battery Connection

4321

12

34

KW-272000-B

1. To positive (+) terminal on starter solenoid.

2. To ground (--) terminal on or near starter motor.

3. To positive (+) terminal on second starter solenoid.

4. To ground (--) terminal on or near second starter motor.

Figure 3-18 24-Volt Engine Electrical System Dual

Starter Motors Typical Battery

Connections

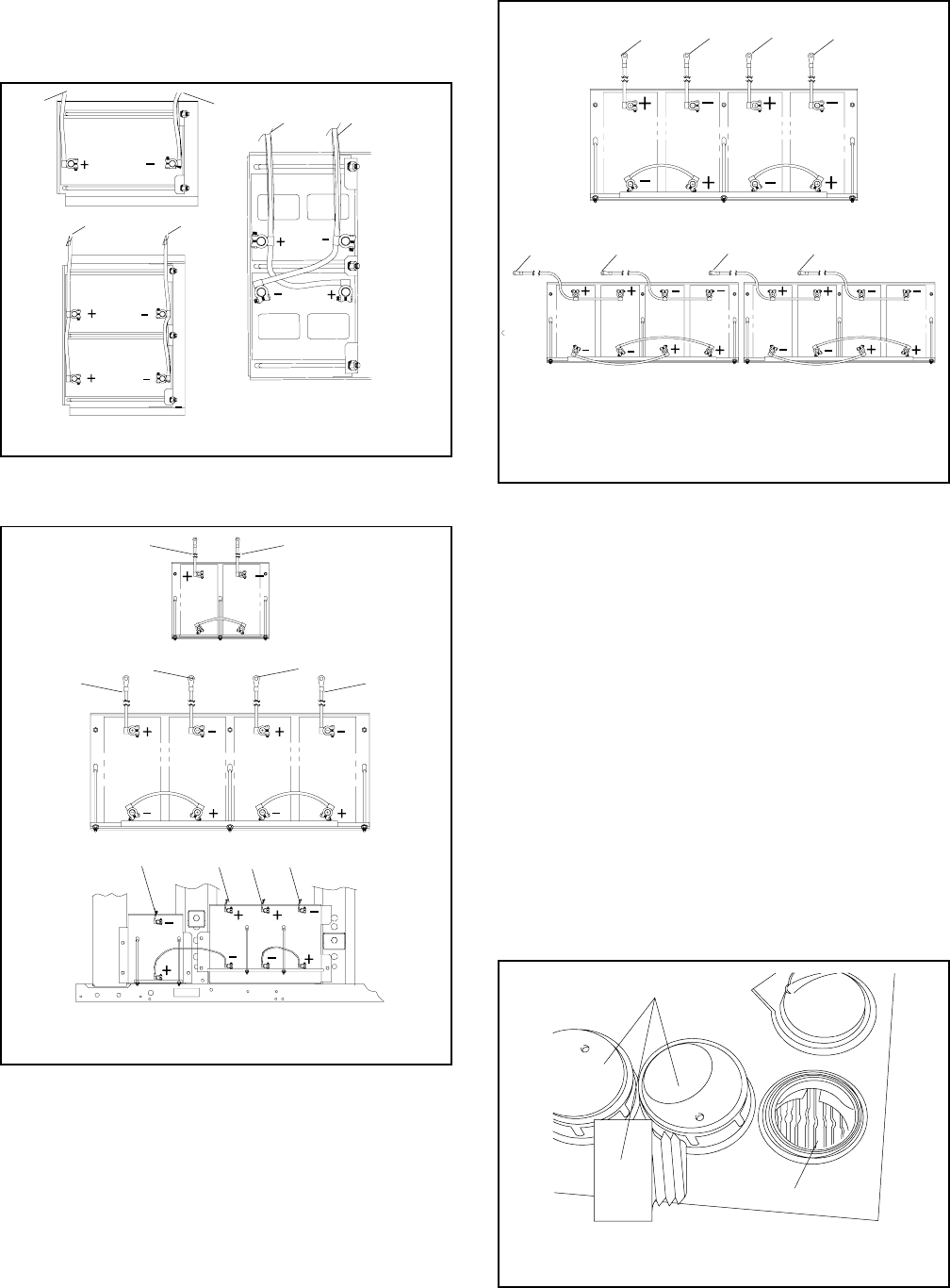

3.11.2 Electrolyte Level Inspection

Check the electrolyte level and specific gravity of

batteries that have filler caps. Maintenance-free

batteries do not require electrolyte l evel checking or

specific gravity testing.

Check the electrolyte level at the specified interval.

Remove the filler caps and verify that the electrolyte

level reaches the bottom of each filler hole. See

Figure 3-19. Refill as necessary with distilled water or

clean tap water. Do not add fresh electrolyte. Tighten

the filler caps. After adding water during freezing

temperatures, run the generator set 20--30 minutes to

mix the electrolyte and the water to prevent battery

damage from freezing.

1-046

1

2

1. Filler caps

2. Electrolyte level

Figure 3-19 Battery Electrolyte Level Inspection