TP-6200 10/12 141Section 3 Scheduled Maintenance

3.5.2 Subbase Fuel Day Tank Electronic

Control Module (ECM)

With an electronic control module (ECM), the optional

subbase diesel fuel tank functions as a day tank.

Following are operating information and features of the

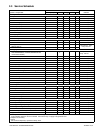

ECM. See Figure 3-2 for the ECM front panel layout.

224825

Figure 3-2 ECM Front Panel Layout

Servicing the day tank. Hazardous voltage can cause

severe injury or death. Service the day tank electrical

control module (ECM) as prescribed in the equipment

manual. Disconnect the power to the day tank before

servicing. Press the day tank ECM OFF pushbutton to

disconnect the power. Notice that line voltage is still present

within the ECM when the POWER ON light is lit. Ensure that

the generator set and day tank are electrically grounded. Do

not operate the day tank when standing in water or on wet

ground because these conditions increase the risk of

electrocution.

ECM General Function

The ECM controls a pump/motor that maintains the day

tank fuel level. The ECM motor relay is connected to the

pump/motor. The ECM starts the pump when the fuel

level drops to 87% of full and stops the pump when the

day tank is full.

ECM Function Indicator LEDs

Two LEDs on the front panel indicate ECM operation.

See Figure 3-2 for the locations of the LEDs. Figure 3-3

describes the LED functions.

Function Description

Power On LED lights to indicate that power is applied

to the ECM.

Pump Running LED lights when the pump starts.

Figure 3-3 ECM Function Indicator LEDs

Level Sensor

An electronic analog float gauge located below the ECM

on the mounting bracket determines the day tank fuel

level. Nine LEDs on the ECM indicate the day tank fuel

levelfromfulltoempty.

ECM Mode

The ECM has three pushbutton switches for normal

operation and one internal test button. See Figure 3-4.

Pushbutton Description

Off Pushbutton disables the ECM for routine

maintenance to the tank system.

On Pushbutton activates the ECM after the

OFF pushbutton is depressed. On

power-up after a power outage, the ECM

automatically turns on.

Test Pushbutton lights front panel LEDs for

3 seconds and activates the pump/motor

for as long as the pushbutton is

depressed. The alarm relays maintain

their original positions.

Internal test Pushbutton (located inside the ECM) tests

each alarm LED and remote annunciation

relay in sequential order (high fuel to ECM

functional).

Figure 3-4 ECM Pushbuttons

ECM Alarms

The ECM has five standard alarm conditions indicated

locally by LEDs and remotely by relays. Figure 3-5

describes the five alarm conditions. Make controller

connections to the normally open and normally closed

relay contacts provided.

Alarm Description

High fuel Alarm activates at 106% of normal fuel

level.

Low fuel Alarm activates at 62% of normal fuel

level. The alarm provides time to respond

to a potential problem before a low fuel

shutdown occurs.

Critical low fuel

(engine shutdown)

Alarm activates at 6% of normal fuel level

to warn the operator to shut down the

generator set before fuel runs out.

Fuel in rupture

basin, if equipped

Alarm activates when the ECM detects

fuel in the rupture basin.

ECM functional Alarm activates to indicate a problem with

the ECM operation.

Note: The ECM functional alarm relay

activates a user-installed alarm when the

relay deenergizes.

Figure 3-5 ECM Alarms