Reelmaster 3550−D Hydraulic SystemPage 4 − 45

Cutting Unit Circuit Testing − Pressure Test:

Cutting unit circuit pressure is the first in a series of tests

recommended to check cutting unit circuit performance.

The results from this test will help determine which com-

ponent(s) are the cause of cutting unit performance is-

sues.

Special Equipment Required:

S Pressure Gauge with extension hose

S Phototach (non−contact tachometer).

1. Park machine on a level surface with the cutting units

lowered, the reel engage/disengage switch in the DIS-

ENGAGE position, and the mow/transport switch in the

MOW position. Make sure engine is off and the parking

brake is disengaged.

2. Make sure backlap knob on the hydraulic manifold is

in the MOW position. Make sure reel speed knob is set

for typical mowing conditions.

3. Read Precautions for Hydraulic Testing in this

chapter.

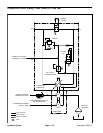

4. Remove cap from test fitting at mow control manifold

port (OR1/G) and install a pressure gauge with hydraulic

hose to the test fitting (Fig. 31).

CAUTION

Keep away from cutting units during test to pre-

vent personal injury from the cutting blades.

5. Sit in the Operator’s seat, start the engine, and move

throttle to full speed (3220 +

50 RPM).

6. Make sure hydraulic fluid is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

7. Verify with a phototach that the pump speed is ap-

proximately 3090 RPM.

8. Set the cutting unit speed control to #9 (maximum)

and engage the cutting units.

When engaged, the cutting circuit pressure may exceed

manifold relief valve pressure setting of 3000 PSI (207

Bar) momentarily opening the relief valve. Circuit pres-

sure should then stabilize at approximately 1200 PSI

(83 Bar).

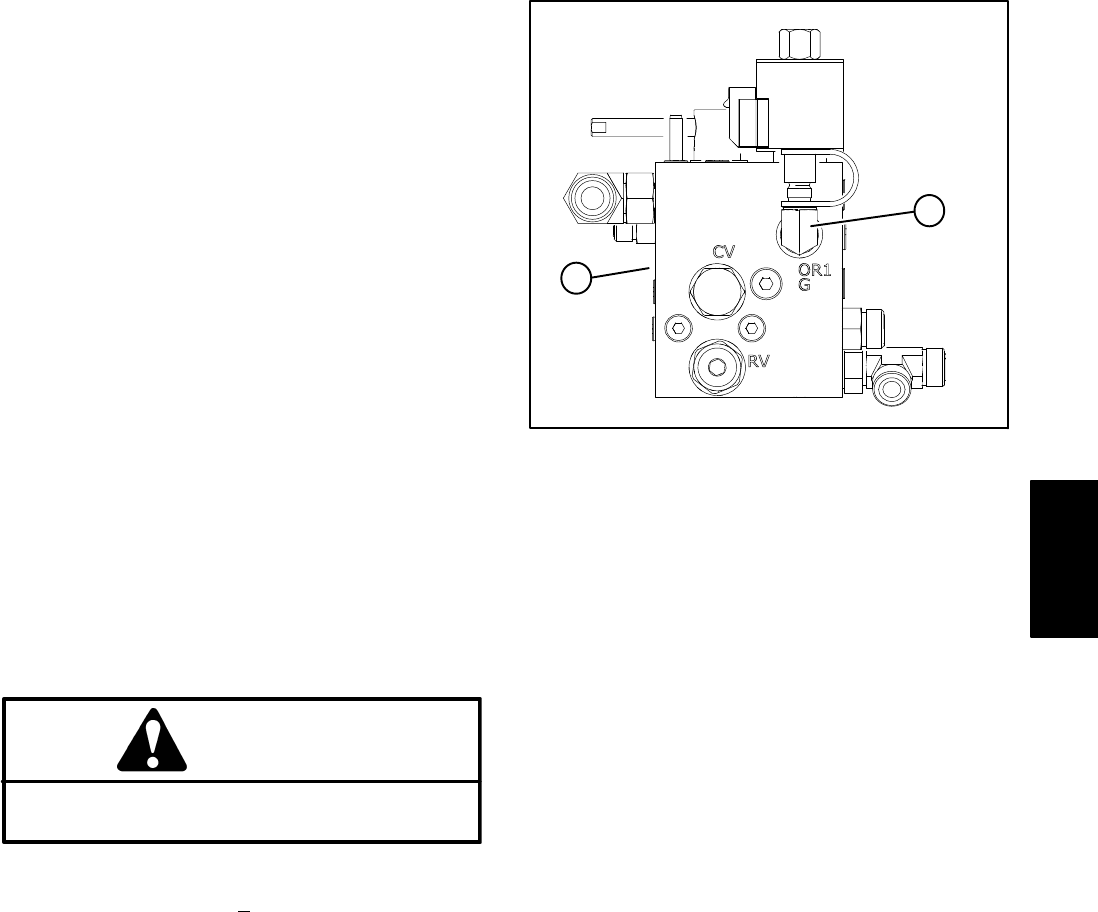

1. Mow control manifold 2. Test fitting (port OR1/G

)

Figure 31

1

2

9. Safely secure the test pressure gauge and operate

the machine under your specific mowing conditions.

Monitor test gauge while mowing. Cutting unit circuit

pressure should be approximately: 1500 to 2000 PSI

(103 to 138 Bar) under low to normal load conditions.

10.Disengage cutting units, move throttle to low speed

and shut off engine.

11.If pressure readings are within specifications and

cutting unit performance is still in question, test cutting

unit motors individually (see Cutting Unit Circuit Testing

− Reel Motor Efficiency/Case Drain Test).

12.If pressure specifications are not met, consider the

following:

A. Proportional relief valve (PRV) is faulty (see Cut-

ting Unit Circuit Testing − Proportional Relief Valve

(PRV) Pressure Test in this chapter).

B. Relief valve (RV) is faulty (see Cutting Unit Circuit

Testing − Relief Valve (RV) Pressure Test in this

chapter).

C. Logic Cartridge (LC) Is faulty (see Control Mani-

fold Cartridge Valve Service in this chapter).

D. Gear pump (P1) is faulty (see Cutting Unit Circuit

Testing − Gear Pump (P1) Flow Under Load Test in

this chapter).

13.Disconnect test equipment from hydraulic manifold.

Hydraulic

System