Reelmaster 3550−D

Cutting Units

Page 7 − 29

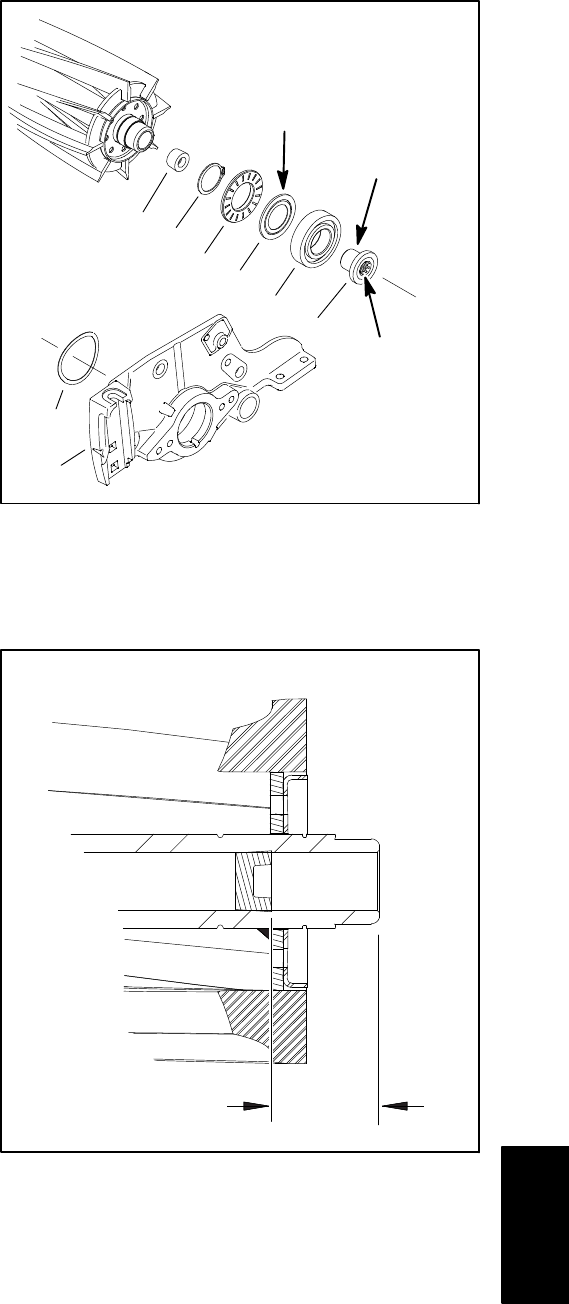

Assembly of Cutting Reel (Fig. 35)

1. If flocked seals and/or bearings were removed from

reel shaft, discard removed components and replace.

2. Make sure that the retaining ring is fully seated into

the groove on the cutting reel shaft.

3. Install special washer with recessed slots toward

bearing. Drive special washer onto reel shaft until it

squarely contacts retaining ring.

4. Slide flocked seal and bearing onto reel shaft with

flocked side of seal against bearing.

5. Install threaded insert.

A. One insert has LH threads and the other insert

has RH threads. The insert with LH threads has a

groove on the insert face. A groove is cut 2.2” (5.6

cm) from the end of the reel shaft to identify the reel

end that has LH threads.

B. For cutting unit serial no. prior to 315000001,

make sure plastic plug is pressed flush into end of

threaded insert. For cutting unit serial no.

315000001 & Up, make sure plastic plug is pressed

unto reel shaft 1.5” (38 mm) below the end of the

shaft (Fig. 37).

C. Use correct spline insert tool to install threaded

inserts (see Special Tools in this chapter).

D. Apply thread locking compound (Loctite #242 or

equivalent) to threaded portion of insert. Tighten

threaded insert from 85 to 95 ft-lb (115 to 128 N−m).

E. Fill threaded insert splines with high temp Mobil

XHP−222 grease or equivalent.

6. Repeat procedure for other end of reel if necessary.

1. Side plate

2. Retaining ring (2)

3. Special washer (2)

4. Flocked seal (2)

5. Bearing (2)

6. Plug (2)

7. Threaded insert LH

8. Wire spring

Figure 36

Loctite #242

85 to 95 ft−lb

(115 to 129 N−m)

Mobil XHP−222

Grease

Flocked

Surface

2

3

4

5

6

7

Toward

Bearing

1

8

or equivalent

1. Reel shaft 2. Plastic plug (2)

Figure 37

1.5” (38 mm)

DPA Cutting

Units