Reelmaster 3550−DPage 5 − 38Electrical System

Fuel Pump

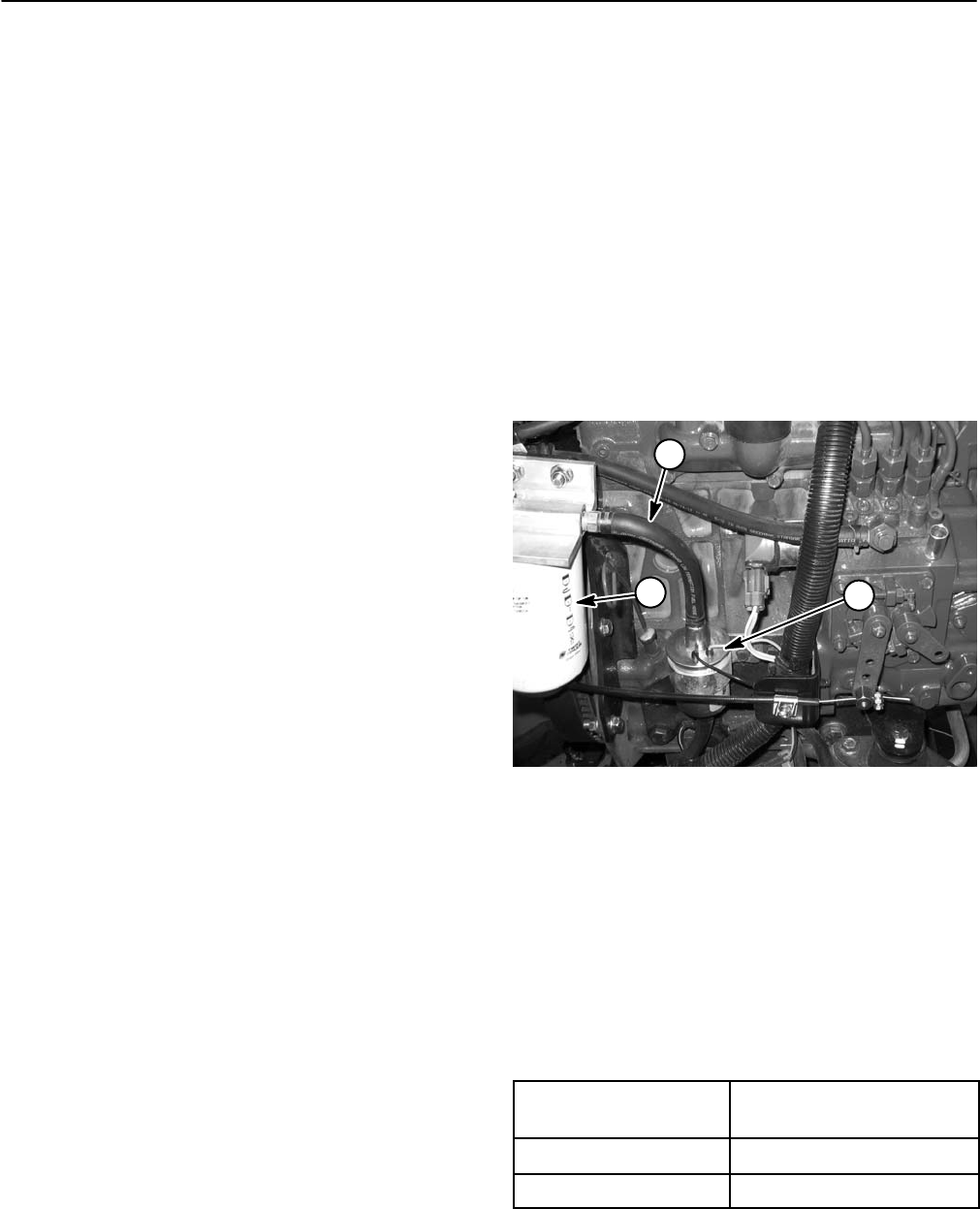

The fuel pump is attached to the left side of the engine

near the fuel/water separator (Fig. 41).

The TEC controller energizes and monitors the opera-

tion of the fuel pump when specific input conditions are

met. The fuel pump is energized when the ignition switch

is set to RUN or START. The fuel pump includes an in-

ternal pressure switch that energizes and de−energizes

the pump to maintain fuel line pressure.

NOTE: The TEC output circuit that controls the electric

fuel pump also controls the fuel stop solenoid. This cir-

cuit is known as the Energize To Run (ETR) circuit. Refer

to the Electrical Schematics and Wire Harness Draw-

ings in Chapter 8 − Foldout Drawings in this manual for

additional information.

Testing

1. Park machine on a level surface, lower cutting units,

stop engine, and engage parking brake. Unlatch and

raise hood.

2. Test the ETR circuit as a TEC electrical output using

the Diagnostic Display (see Diagnostic Display in this

chapter). If output testing verifies that the TEC is ener-

gizing the ETR circuit under the appropriate conditions,

leave the diagnostic display connected test the circuit

wiring.

3. Test the circuit wiring:

A. Disconnect wire harness connector from the fuel

pump.

B. Position the necessary input(s) to illuminate the

ETR output LED indicating that the TEC controller is

energizing that function (see Table 3: Input Condi-

tions Required to Illuminate Diagnostic Display Out-

puts in this chapter).

C. Connect multimeter (DC voltage setting) across

the terminals of the wire harness connector. 12VDC

should be present at the connector when the ETR

LED is illuminated.

D. Repair damaged wiring as necessary.

4. If the circuit wiring is functioning correctly, use the fol-

lowing procedure to test the pump.

A. Disconnect electrical connector from the fuel stop

solenoid to prevent the engine from starting.

B. Disconnect the fuel hose between the pump and

the filter/separator (pump discharge) at the filter sep-

arator.

C. Make sure fuel hoses to and from the fuel pump

are not kinked, damaged, and free of obstructions.

D. Place disconnected fuel hose into a graduated

cylinder with at least a 1 quart (0.95 liter) capacity.

IMPORTANT: When testing the fuel pump, DO

NOT turn ignition switch to START.

E. Collect fuel in the graduated cylinder by turning

ignition switch to the RUN position. Allow pump to

run for time listed below, then return switch to OFF.

The amount of fuel collected in the graduated cylin-

der should be approximately 21 to 37 fl oz (0.62 to

1.1 Ltr) after thirty (30) seconds.

1. Fuel pump

2. Fuel hose (discharge)

3. Fuel filter

Figure 41

2

1

3

5. Replace fuel pump as necessary. Reconnect fuel

hose to the fuel filter/separator.

6. Reconnect electrical connector to the fuel stop sole-

noid.

7. Bleed fuel system.

Fuel Pump Specifications

Pump Capacity

42 to 74 fl oz/min

(1.2 to 2.2 Ltr/min)

Pressure 2.3 psi (15.8 kPa)

Max. Current Draw 1.8 amp