Reelmaster 3550−D Hydraulic SystemPage 4 − 35

Traction Circuit Testing − Charge Pressure Test:

The charge pressure test is the first in a series of tests

recommended to determine traction circuit perform-

ance. A charge pressure drop of more than 20% indic-

ates an internal leak in the piston pump/hydrostat.

Continued unit operation can generate excessive heat,

cause damage to seals and other components in the hy-

draulic system, and affect overall machine perform-

ance.

Special Equipment Required:

S Pressure Gauge

S Flow Meter with Pressure Gauge that has at least

an 18 GPM (68 LPM) capacity.

S Phototach (non−contact tachometer).

1. Park machine on a level surface with the cutting units

lowered and the reel engage/disengage switch is in the

disengage position. Make sure engine is off and the

parking brake is engaged.

2. Read Precautions for Hydraulic Testing in this

chapter.

3. Make sure that traction pedal is adjusted to the neu-

tral position.

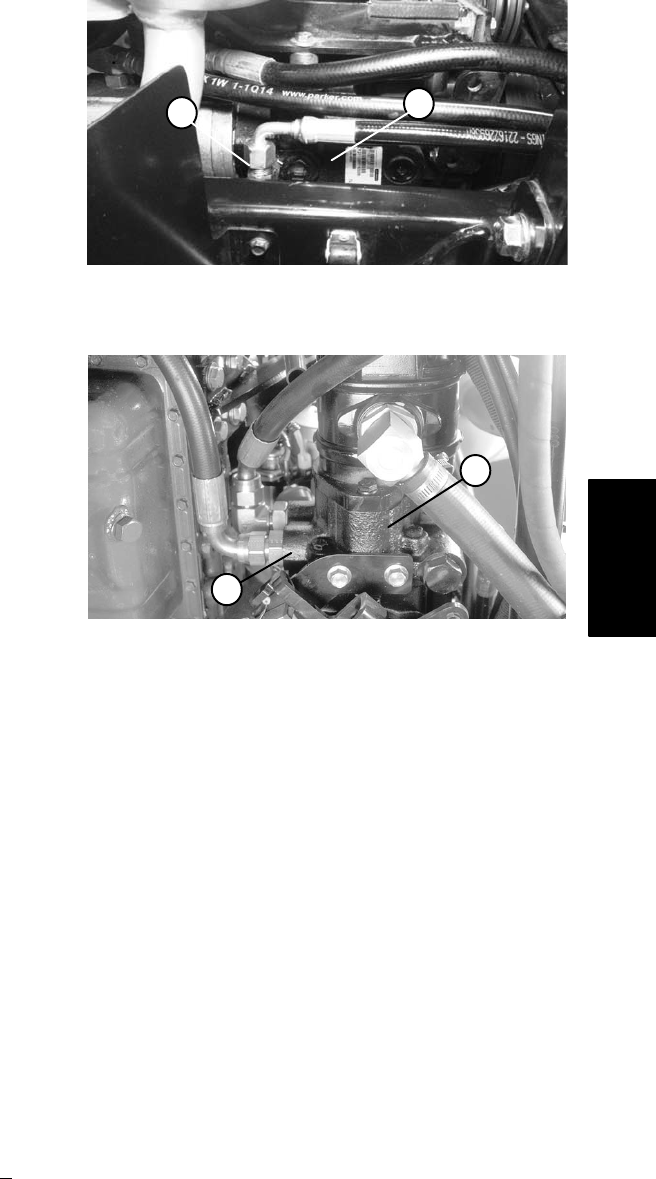

4. Disconnect the upper hose at the tee fitting on the

piston pump/hydrostat. This hose comes from the steer-

ing control valve (T) port (Fig. 25).

5. Install a T−connector and pressure gauge between

the fitting and disconnected hose.

6. Disconnect hose from the lower hydraulic fitting on

the engine side of the hydrostat (Fig. 26).

7. Install tester in series with the pump and the discon-

nected hose. Make sure the tester flow control valve is

fully open.

8. Attach a heavy chain to the rear of the machine frame

and an immovable object to prevent the machine from

moving during testing.

9. Chock the wheels to prevent wheel rotation during

testing.

10.Start engine. Move throttle to full speed (3220 +

50

RPM).

11.Make sure hydraulic fluid is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

12.Verify with a phototach that the pump speed is ap-

proximately 3090 RPM.

1. Hydraulic tee fitting 2. Piston pump

Figure 25

1

2

1. Lower hydraulic fitting 2. Piston pump

Figure 26

1

2

13.Record reading on pressure gauge from the lift con-

trol manifold (T) port. Charge pressure (without load)

should read from 150 to 200 PSI (10.3 to13.8 Bar). If

charge relief pressure specification is not met, consider

the following:

A. Gear pump (P2) is faulty (steering/lift circuit per-

formance will also be affected). Test gear pump (P2)

flow (see Gear Pump (P2) Flow Test in this chapter).

B. The piston pump charge relief valve is faulty. Re-

pair or replace the piston pump charge relief valve

(see Piston Pump Service in this chapter).

14.Sit in the operator’s seat, release the parking brake,

and slowly depress the forward traction pedal until 1000

to 1500 PSI (68.9 to 103.4 Bar) is reached on the flow

meter pressure gauge.

15.Record reading on pressure gauge from lift control

manifold (T) port (under load). Charge pressure (under

load) should not drop more than 20% when compared

to charge pressure (without load) recorded in step 13.

If specifications are not met, perform Piston Pump/Hy-

drostat Flow and Traction Relief Pressure Test as out-

lined in this chapter.

16.Release traction pedal, move throttle to low speed

and turn the engine off.

Hydraulic

System