Reelmaster 3550−D Hydraulic SystemPage 4 − 77

7. Label all hydraulic hoses and fittings for assembly

purposes.

8. Disconnect all hydraulic hoses connected to the hy-

draulic fittings on the piston pump/hydrostat and gear

pump. Allow hoses to drain into a suitable container.

Plug hose and fitting openings to prevent contamina-

tion.

CAUTION

Support pump assembly during removal to pre-

vent them from falling and causing personal in-

jury or component damage.

9. Support hydraulic pump assembly to prevent it from

shifting.

10.Remove both flange head screws and flange nuts

that secure pump support to engine mount.

11.Remove fasteners and spacers securing the pump

mount plate to the engine (Fig. 47). Note location of cap

screws, washers and spacers for assembly purposes.

12.Carefully remove pump mount plate with pumps,

pulley, pump support and idler assembly from the ma-

chine.

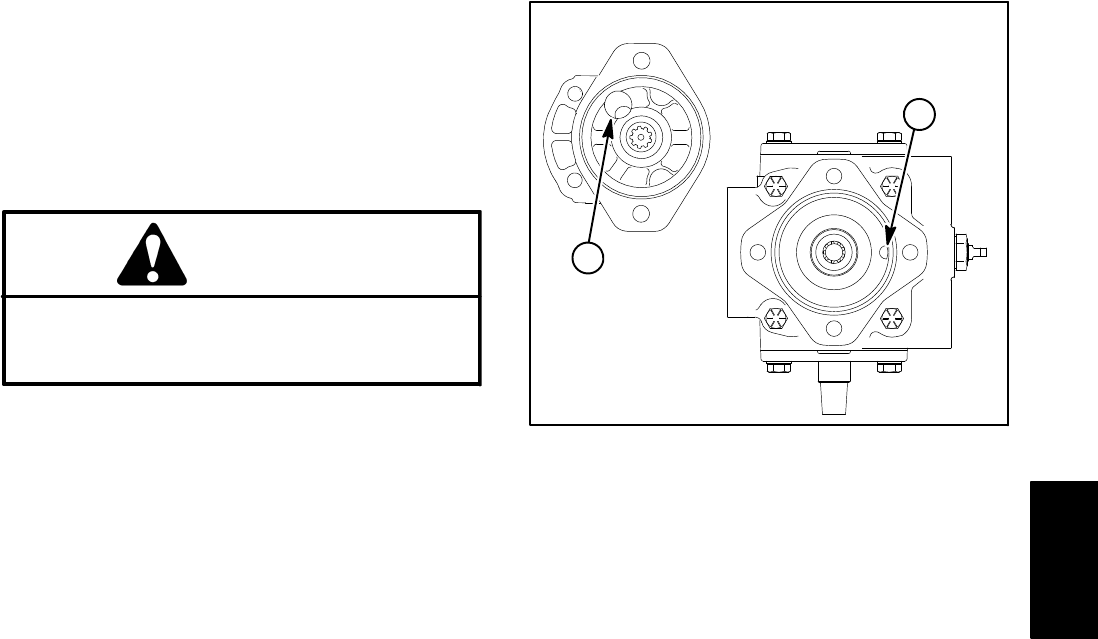

NOTE: A case drain exists in the piston pump/hydrostat

and a suction port is near the input shaft of the gear

pump (Fig. 48). When the gear pump is removed from

the piston pump/hydrostat, plug both case drain holes to

prevent draining the pumps.

13.Remove both cap screws and flat washers securing

gear pump to the piston pump. Separate gear pump

from the piston pump. Locate and retrieve O−ring. Plug

openings of gear pump to prevent contamination.

14.Remove pump pulley from the taper lock bushing on

the piston pump shaft:

A. Remove three (3) cap screws and lock washers

securing pulley to the taper lock bushing.

IMPORTANT: Excessive or unequal pressure on

the cap screws can break the bushing flange.

B. Insert cap screws into threaded removal holes of

the pulley. Tighten screws progressively and evenly

until the pulley is loose on the bushing. Remove

pulley from the bushing.

15.Loosen set screw that secures taper lock bushing to

piston pump shaft. Remove bushing from the pump

shaft. Locate and retrieve key from pump shaft.

1. Piston pump/hydrostat

case drain

2. Gear pump suction por

t

Figure 48

Remove plugs before installing

gear pump to piston pump

2

1

16.Remove both cap screws and washers that secure

piston pump to pump support. Locate and retrieve

spacers.

17.Remove lock nuts, flat washers and cap screws that

secure the piston pump to the pump mount plate. Re-

move pump from plate.

18.If hydraulic fittings are to be removed from piston

pump, mark fitting orientation to allow correct assembly.

Remove hydraulic fittings and O−rings from the piston

pump as needed. Discard removed O−rings.

Piston Pump Installation (Fig. 44 and 47)

1. Position and secure piston pump to the pump mount

plate with cap screws, flat washers and lock nuts.

2. Lubricate and place new O−rings onto all removed

pump fittings. Install fittings into pump openings using

marks made during the removal process to properly

orientate fittings. Tighten fittings (see Hydraulic Fitting

Installation in this chapter).

IMPORTANT: A case drain exists in the piston

pump/hydrostat and a suction port is near the input

shaft of the gear pump (Fig. 48). Before the gear

pump is installed to the piston pump, make sure that

plugs placed in either of these ports are removed.

Failure to remove plugs will cause excessive pres-

sure in the piston pump and damage seals. Also, be-

fore installing gear pump to piston pump, fill piston

pump housing with clean hydraulic oil through case

drain hole.

3. Install and secure gear pump to the piston pump (see

Gear Pump in this chapter).

Hydraulic

System