Reelmaster 3550−DHydraulic System Page 4 − 30

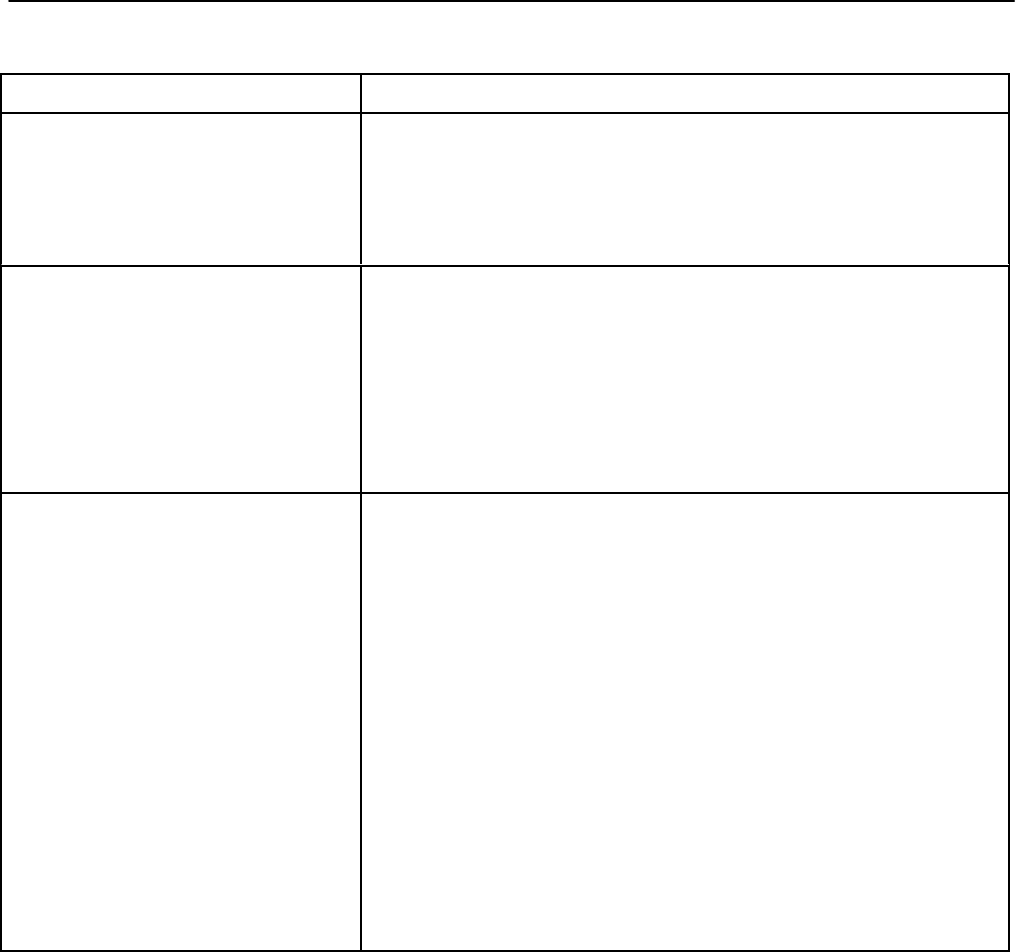

Mow Circuit Problems

Problem Possible Cause

Gear pump is noisy (cavitation). Hydraulic tank oil level is low

(NOTE: Other hydraulic systems are affected as well).

Suction line is restricted.

Suction line has an air leak.

None of the cutting reels will turn.

NOTE: To engage the mow circuit,

the seat must be occupied, the cut-

ting units must be fully lowered, the

mow/transport switch must be in the

MOW position and the reel enable/

disable switch must be in the EN-

ABLE position.

Solenoid valve (PRV) is stuck open.

An electrical problem exists that prevents the PRV solenoid valve in

mow control manifold from being energized (See Chapter 5 − Elec-

trical System in this manual).

Gear pump is worn or damaged.

Poor after−cut appearance (cutting

blades(s) turn too slowly).

NOTE: If possible, have another

person observe the machine while

mowing in dense turf prior to hy-

draulic testing. A bad reel motor

will run slower, produce fewer clip-

pings, and may cause marcelling

(a washboard appearance) on the

turf.

All Cutting Units:

Flow control (FC) in mow control manifold requires adjustment.

Solenoid valve (PRV) is faulty.

Gear pump (P1) is inefficient (see Testing in this chapter).

One or more Cutting Units:

Cutting unit motor has internal leakage (see Testing in this

chapter).

Rear Cutting Units:

Relief valve (RV) is out of adjustment or faulty.

Single Cutting Unit:

Cutting unit reel bearing(s) is (are) damaged.