Reelmaster 3550−D Hydraulic SystemPage 4 − 37

Traction Circuit Testing − Wheel Motor Efficiency

Test:

Wheel motor efficiency is the second in a series of tests

recommended to determine traction circuit perform-

ance. Hydraulic fluid flow of 1.5 GPM (5.7 LPM) or more

through a stationary wheel motor under load indicates

an internal leak in the wheel motor. A worn wheel motor

is less efficient. Eventually, enough fluid by−pass will

cause the wheel motor to stall under heavy load condi-

tions. Continued operation can generate excessive

heat, cause damage to seals and other components in

the hydraulic system, and affect overall machine per-

formance.

There are moments during wheel motor operation (ger-

oller position) when fluid flow through the motor is less

restricted. If a wheel motor is tested in this position, the

test results will be higher should not be used to determ-

ine wheel motor efficiency. Test wheel motors in three

(3) different wheel positions to obtain accurate test res-

ults. Record test readings for all three (3) wheel posi-

tions.

Hydraulic fluid flows through both front wheel motors (in

parallel) before passing through the rear wheel motor (in

series). In this configuration, the rear wheel motor can

mask front wheel motor performance issues, and the

front wheel motors can mask rear wheel motor perform-

ance issues. Start by testing both front wheel motors to-

gether, then individually if necessary. Finish by testing

the rear wheel motor.

Special Equipment Required:

S Pressure Gauge

S Flow Meter with Pressure Gauge that has at least

an 18 GPM (68 LPM) capacity

S Phototach (non−contact tachometer)

1. Park machine on a level surface with the cutting units

lowered and the reel engage/disengage switch is in the

disengage position. The engine should be off and the

parking brake engaged.

2. Read Precautions for Hydraulic Testing in this

chapter.

3. Make sure that traction pedal is adjusted to the neu-

tral position.

4. Attach a heavy chain to the rear of the machine frame

and an immovable object to prevent the machine from

moving during testing.

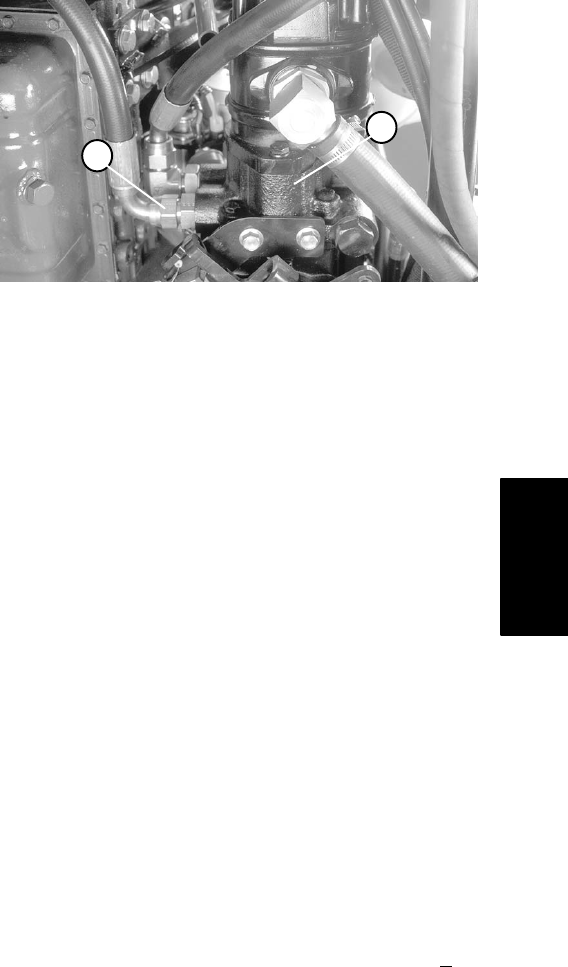

1. Lower hydraulic fitting 2. Piston pump

Figure 28

1

2

Front Wheel Motor Test:s

Hydraulic fluid flows through both front wheel motors (in

parallel) before passing through the rear wheel motor (in

series). To accurately test the front wheel motors, the

rear wheel motor must be removed from the traction cir-

cuit.

1. Disconnect hose from the lower hydraulic fitting on

the bottom of the hydrostat (Fig. 28).

NOTE: An alternate testing location would be at the hy-

draulic hose from the hydrostat and the hydraulic tube

supplying the front wheel motors under the left floor

plate.

2. Install flow tester between the hydrostat and the dis-

connected hose. Make sure the tester flow control valve

is fully open.

3. Disconnect both hydraulic lines from the rear wheel

motor, then reconnect the lines to each other. Plug ports

in wheel motor to prevent contamination.

4. Chock front wheels to prevent wheel rotation.

5. Start engine. Move throttle to full speed (3220 +

50

RPM).

6. Make sure hydraulic fluid is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

Hydraulic

System