Reelmaster 3550−D

Cutting Units

Page 7 − 15

Service and Repairs

Cutting Unit Reel Motor

1. Park the machine on a level surface, engage parking

brake, lower cutting units and stop engine. Remove key

from the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components in this chapter.

3. Label all hydraulic connections for assembly purpos-

es. Thoroughly clean hydraulic connections prior to

loosening hydraulic lines from reel motor to prevent hy-

draulic system contamination.

CAUTION

Before opening hydraulic system, operate all hy-

draulic controls to relieve system pressure and

avoid injury from pressurized hydraulic oil. See

Relieving Hydraulic System Pressure in the Gen-

eral Information section of this chapter.

4. Disconnect hydraulic hoses from fittings in reel mo-

tor. Allow lines to drain into a suitable container. Remove

and discard O−rings.

5. Put caps or plugs on disconnected hoses and fittings

to prevent contamination.

6. Loosen two (2) flange nuts or flange head screws

that secure the hydraulic reel motor to the cutting unit

side plate (Fig. 20). Rotate motor clockwise and remove

motor from cutting unit.

7. Inspect the O−ring on the reel motor flange and re-

place O−ring if damaged.

8. If hydraulic fittings are to be removed from motor,

mark fitting orientation to allow correct assembly. Re-

move fittings from motor and discard O−rings.

NOTE: See Cutting Unit Reel Motor Service in Chapter

4 − Hydraulic System in this manual for additional reel

motor service information.

Installation

1. If hydraulic fittings were removed from motor, lubri-

cate new O−rings, position O−rings to fittings and install

fittings into motor ports (see Hydraulic Fitting Installation

in this chapter). Make sure that fittings are orientated

correctly.

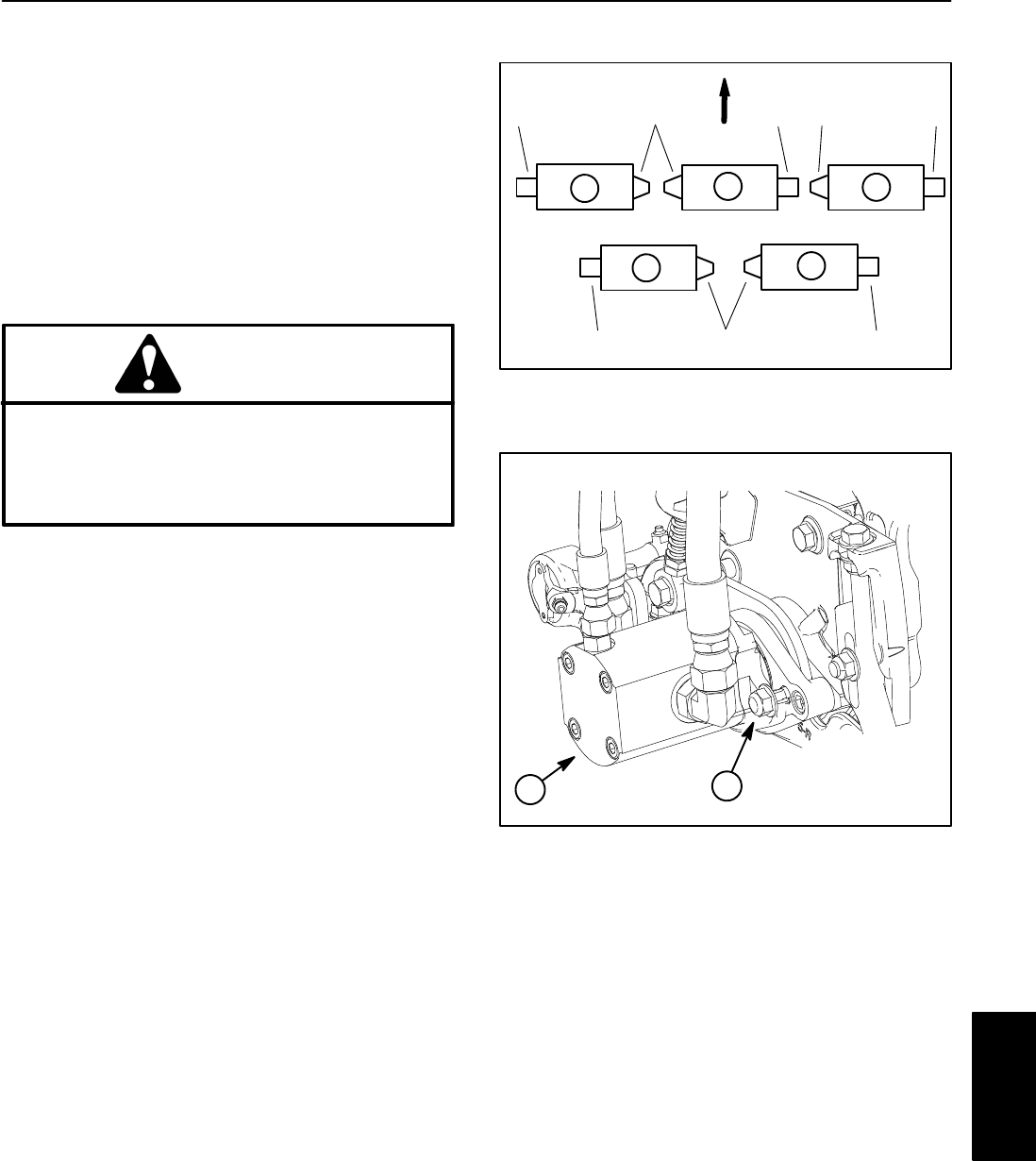

1. Reel motor location 2. Weight location

Figure 19

FRONT

3

4

5

1

2

1

2

2

1

1

2 11

1. Hydraulic reel motor 2. Flange nut or flange

head screw (2)

Figure 20

2

1

2. Coat spline shaft of the reel motor with No. 2 multi-

purpose lithium base grease. Lubricate the O−ring on

the motor flange with clean oil.

3. Rotate the motor clockwise so the motor flanges

clear the flange nuts in the cutting unit side plates. Align

reel motor shaft splines with cutting reel insert splines.

Slide motor shaft into reel insert.

4. Rotate the motor counter−clockwise until the motor

flanges are encircling the cap screws in the side plates.

While holding motor, tighten two (2) flange nuts or flange

head screws to secure reel motor to cutting unit

(Fig. 20).

DPA Cutting

Units