Reelmaster 3550−DPage 5 − 6Electrical System

Troubleshooting

CAUTION

Remove all jewelry, especially rings and

watches, before doing any electrical trouble-

shooting or testing. Disconnect the battery

cables unless the test requires battery voltage.

For effective troubleshooting and repairs, there must be

a good understanding of the electrical circuits and com-

ponents used on this machine (see Chapter 8 − Foldout

Drawings in this manual).

If the machine has any interlock switches by−passed,

reconnect the switches for proper safety and trouble-

shooting.

NOTE: Use the Diagnostic Display (see Special Tools

in this chapter) to test Electronic Control Module inputs

and outputs when troubleshooting an electrical problem

on your Reelmaster.

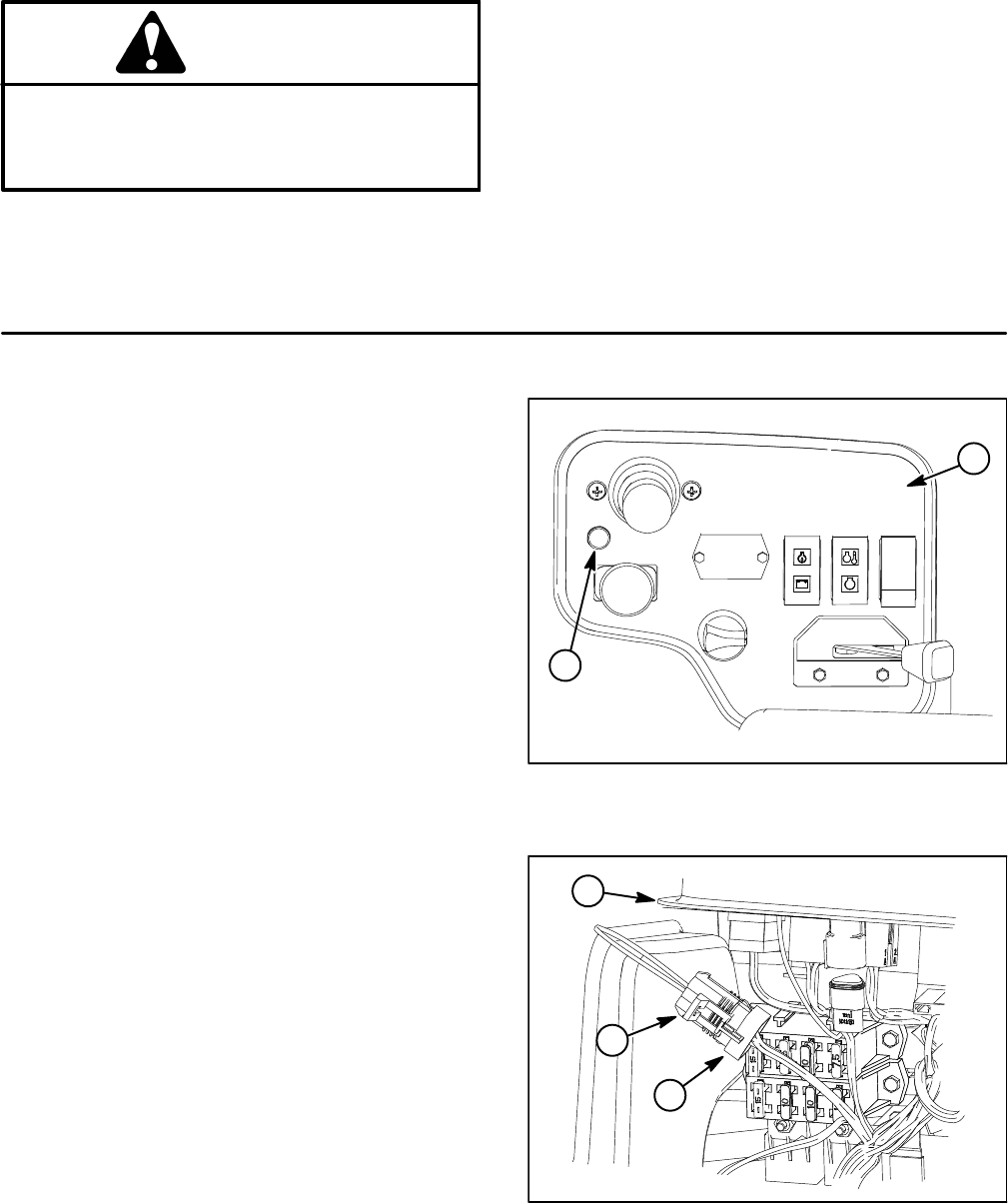

Diagnostic Light

Reelmaster 3550−D machines are equipped with a

diagnostic light that indicates if the machine electrical

system is functioning correctly. The diagnostic light is lo-

cated on the control panel (Fig. 7).

When the ignition switch is moved to the RUN position

and the machine electrical system is functioning pro-

perly, the diagnostic light will be illuminated for approxi-

mately three (3) seconds and then will turn off. The light

should remain off during normal machine operation.

If the machine TEC controller detects an electrical sys-

tem malfunction (fault) during machine operation, the

diagnostic light will flash rapidly. The light will stop flash-

ing and will automatically reset when the ignition switch

is turned to the OFF position. The fault, however, will be

retained in controller memory and can be retrieved at a

future time (see Retrieving Fault Codes below).

If the diagnostic light does not illuminate when the igni-

tion switch is turned to the RUN position, possible

causes are:

D The loopback connector located below the con-

trol panel is not connected to the wire harness

(Fig. 8).

D The diagnostic light (or circuit wiring) is faulty.

D TEC controller fuses are faulty (see Fuses in this

chapter).

D The TEC controller is faulty.

Test electrical connections, controller fuses and the

diagnostic light to determine malfunction. Make sure

that the loopback connector is secured to the wire har-

ness connector.

1. Control panel 2. Diagnostic light

Figure 7

2

1

Figure 8

1. Control panel

2. Loopback connector

3. Harness connector

1

2

3