Reelmaster 3550−D

Cutting Units

Page 7 − 26

7. Remove cap screw and flat washer that secure rear

grass shield to LH side plate.

8. Remove flange head screw and flange nut that se-

cures frame spacer and carrier frame to LH side plate.

NOTE: The reel bearings and grease seals are press fit

on the cutting reel shaft and should remain on the reel

when removing the LH side plate.

9. Remove two (2) shoulder bolts and flange nuts that

secure the LH side plate to the cutting unit frame. Re-

move the LH side plate from the reel shaft and cutting

unit frame.

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when removing the cutting reel.

10.Carefully slide the cutting reel assembly from the RH

side plate.

11.Inspect and service cutting reel assembly as re-

quired (see Reel Assembly Service in this chapter).

Installation (Fig. 32 & 33)

1. Thoroughly clean side plates and other cutting unit

components. Inspect side plates for wear or damage

and replace if needed.

2. Make sure that grease seals and bearings are prop-

erly installed on cutting reel (see Reel Assembly Service

in this Chapter).

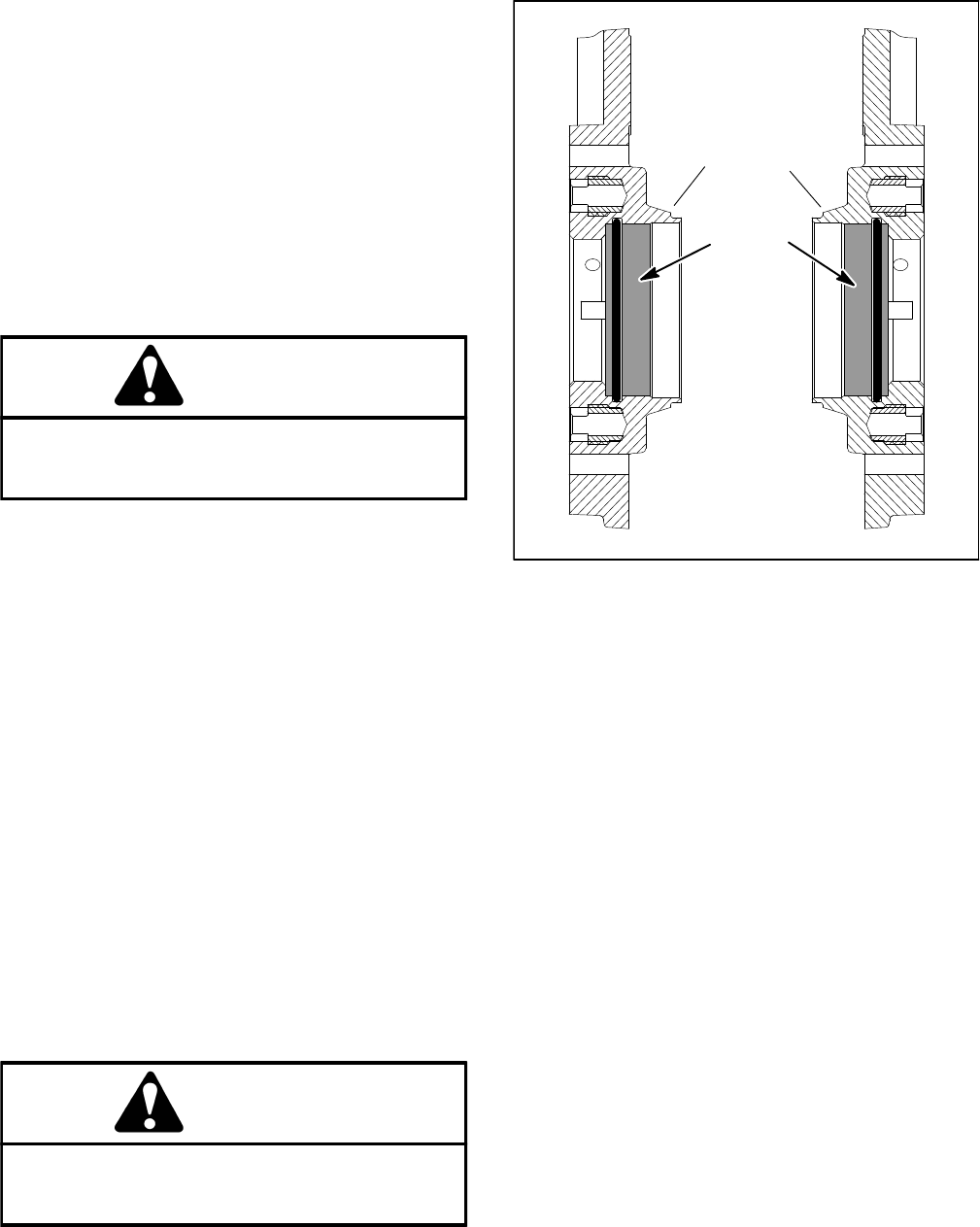

3. Cutting unit serial nos. 315000001 & Up have

O−rings in the reel bearing bore of each side plate. Make

sure the O−rings are in good condition and properly in-

stalled in the side plates.

4. Apply a thin coat of antiseize lubricant to the reel

bearing bore of each side plate (Fig. 34).

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when installing the cutting reel.

5. Carefully slide the RH end of the cutting reel as-

sembly (no groove in reel shaft or on face of threaded

insert) into the RH side plate. Make sure that bearing is

fully seated into side plate.

1. Side plate − RH 2. Side plate − LH

Figure 34

12

Antiseize

Lubricant

6. Slide the LH side plate onto the cutting reel as-

sembly.

7. Install shoulder bolts and flange nuts that secure the

LH side plate to the cutting unit frame. Torque the shoul-

der bolts from 27 to 33 ft-lbs (37 to 44 N−m).

8. Apply Loctite #242 (or equivalent) to threads of

flange head screw that secures frame spacer and carri-

er frame to LH side plate. Install screw and torque from

27 to 33 ft-lbs (37 to 44 N−m). After tightening screw,

check the clearance between the carrier frame and side

plate. If clearance is more than 0.065” (1.6 mm), re-

move flange head screw and position shim(s) between

carrier frame and side plate so that clearance is less

than 0.065” (1.6 mm). Make sure that the carrier frame

pivots freely after assembly.

9. Install cap screw and flat washer that secure rear

grass shield to LH side plate. Torque screw from 15 to

19 ft-lbs (20 to 25 N−m).

10.Install the bedbar assembly (see Bedbar Installation

in this section).

11.Install front and rear rollers (see Front Roller Installa-

tion and Rear Roller Installation in this section).

12.Adjust cutting unit (see Cutting Unit Operator’s

Manual).