Reelmaster 3550−DPage 5 − 32Electrical System

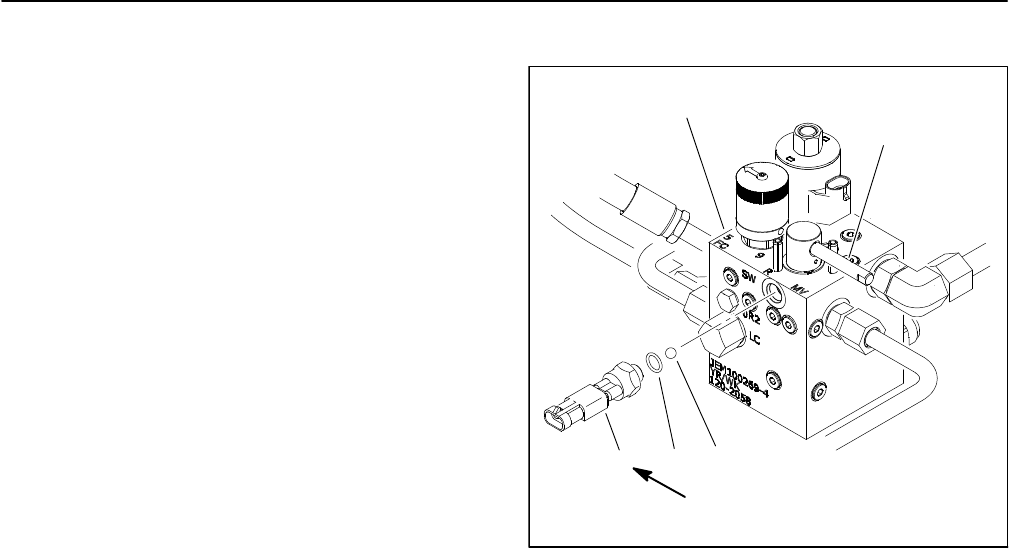

Backlap Switch

The backlap switch is a normally open ball switch that is

in the normal, open state when the backlap lever is in the

mow position. When the backlap lever is in the backlap

position, the switch closes. The backlap switch is at-

tached to the hydraulic mow control manifold located on

the left side of the machine under the hinged access

panel in front of the operator’s seat (Fig. 34).

The TEC controller monitors the position of the backlap

switch (open or closed). Using inputs from the backlap

switch and other switches in the interlock system, the

TEC controller controls the energizing of solenoid valve

(MV) used to reverse the direction of the cutting unit reel

motors (see Table 3: Input Conditions Required to Illu-

minate Diagnostic Display Outputs in this chapter).

Testing

1. Park vehicle on a level surface, stop engine, apply

parking brake and remove key from ignition switch.

2. Before disconnecting the seat switch for testing, the

switch and its circuit wiring should be tested as a TEC

electrical input using the Diagnostic Display (see Diag-

nostic Display in this chapter). If input testing verifies

that the seat switch and circuit wiring are functioning cor-

rectly, no further switch testing is necessary. If, however,

input testing determines that the seat switch and circuit

wiring are not functioning correctly, proceed with the fol-

lowing switch testing procedure.

3. Raise the hinged access panel and locate the back-

lap switch on the front of the mow control manifold (left

side). Disconnect the harness electrical connector from

the backlap switch.

4. Check the continuity of the switch by connecting a

multimeter (ohms setting) across the switch connector

terminals.

5. With the ignition switch in the OFF position, turn the

backlap lever to the backlap position while watching the

multimeter. Continuity should be made as the switch

closes.

1. Mow control manifold

2. Backlap switch

3. O−ring

4. Ball

5. Backlap lever

Figure 34

1

5

2

3

4

20 ft−lb (27 N−m)

6. Turn the backlap lever to the mow position while

watching the multimeter. Continuity should be broken as

the switch opens.

7. If backlap switch is faulty, replace switch. Make sure

that dowel and ball are placed in the manifold port before

installing new switch in manifold. Torque switch to 20 ft-

lb (27 N- m).

8. If the backlap switch tests correctly and a circuit

problem still exists, check wire harness (see Electrical

Schematic and Wire Harness Drawings in Chapter 9 -

Foldout Drawings in this manual).

9. After testing is completed, connect harness electric-

al connector to the backlap switch and close access

panel.