Reelmaster 3550−D Hydraulic SystemPage 4 − 103

NOTE: The ports on the mow control manifold are

marked for easy identification of components. Example:

PRV is the proportional relief valve and T is the return

port (see Hydraulic Schematic to identify the function of

the hydraulic lines and cartridge valves at each port

location).

NOTE: The hydraulic manifold shown uses several

zero leak plugs. These plugs have a tapered sealing

surface on the plug head that is designed to resist vibra-

tion induced plug loosening. The zero leak plugs also

have an O−ring to provide a secondary seal. If zero leak

plug removal is necessary, lightly rap the plug head us-

ing a punch and hammer before using an allen wrench

to remove the plug: the impact will allow plug removal wi-

th less chance of damage to the socket head of the plug.

When installing plugs into the manifold, torque plugs to

the values shown.

NOTE: The mow control manifold includes two (2) ori-

fice fittings. The 0.020” orifice threads into manifold port

OR2 under a hex plug. The 0.050” orifice threads into

manifold port OR1 under the diagnostic test fitting.

Cartridge Valve Service

The mow control manifold includes an adjustable relief

valve (RV). Mow control manifold relief valve (RV)

should be set to 1500 PSI (103 Bar). Adjust the relief

valve to the recommended setting as necessary (see

Adjustments in this chapter).

For cartridge valve service procedures, see Cartridge

Valve Service in this chapter. When installing cartridge

valves into the manifold, torque cartridge valves to the

values shown.

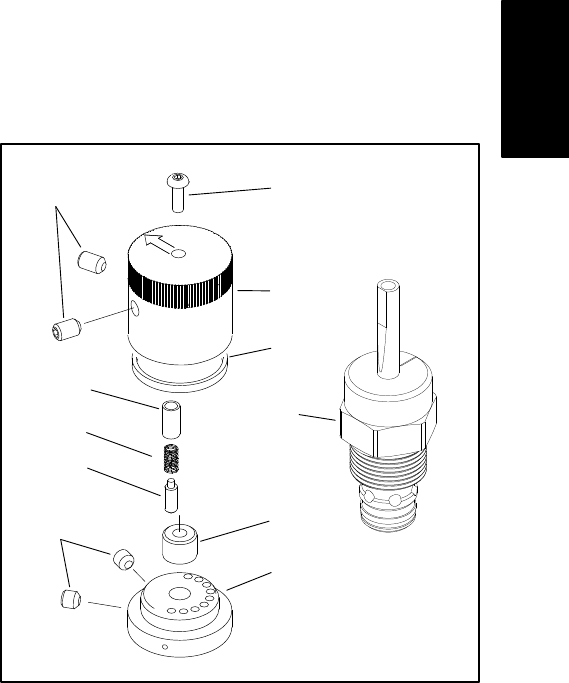

Rotary Handle Assembly (Fig. 67)

1. To remove rotary handle from valve:

A. Loosen two (2) set screws that secure handle

cap.

B. Remove screw and then lift handle cap from

valve.

C. Locate and retrieve detent pin, compression

spring, bushing and lip seal. The sleeve bearing

should stay in the cap.

D. Loosen two (2) set screws that secure handle

base to flow control valve and remove base.

2. To install rotary handle:

IMPORTANT: Make sure that flow control cartridge

valve is properly secured in manifold before instal-

ling rotary handle to valve.

A. Place handle base on flow control valve and posi-

tion alignment mark on base with number 1 on man-

ifold. Secure base with two (2) set screws. Apply a

light coating of grease to chamfer on top of base to

ease seal installation.

B. Make sure that sleeve bearing is in handle cap. If

necessary, press sleeve bearing into cap. Install lip

seal on cap with seal lip facing down.

C. While pressing on the cap to keep the lip seal in

place, rotate cap in a clockwise direction until the ar-

row on the cap aligns with number 1 on the manifold.

By rotating the cap clockwise, the valve will remain

closed. Install screw to retain cap.

D. Make sure that alignment marks on cap and base

are in line and that arrow on cap is pointing to number

1 on manifold. Tighten two (2) set screws to secure

handle cap.

1. Handle base

2. Handle cap

3. Detent pin

4. Compression spring

5. Bushing

6. Set screw (2)

7. Set screw (2)

8. Screw

9. Lip seal

10. Sleeve bearing

11. Flow control valve

Figure 67

6

5

4

7

9

10

3

2

8

1

11

Hydraulic

System