Reelmaster 3550−D Page 5 − 37 Electrical System

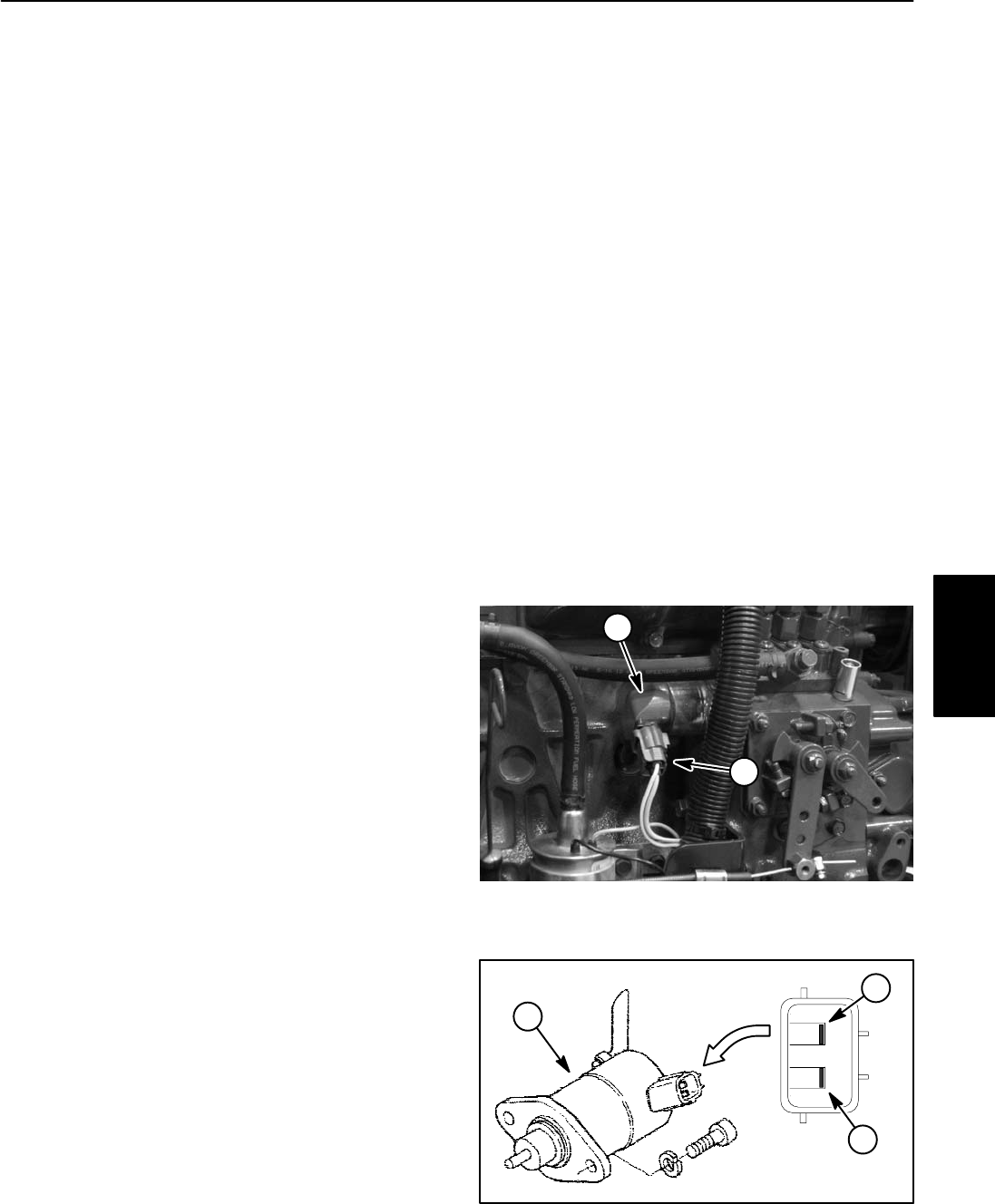

Fuel Stop Solenoid

The fuel stop solenoid must be energized for the diesel

engine to run. The solenoid is mounted to the injection

pump on the engine (Fig. 39).

The fuel stop solenoid includes two coils for operation:

the pull coil and the hold coil. The TEC controller ener-

gizes and monitors the operation of the fuel stop solen-

oid when specific input conditions are met. When the

ignition switch is set to RUN or START, the fuel stop sole-

noid is energized and the pull coil retracts the solenoid

plunger. Once the plunger is retracted, the hold coil will

keep it retracted for continued engine operation. When

the solenoid is de−energized, the plunger extends to

shut off fuel supply to the engine causing the engine to

stop running. The fuel stop solenoid is grounded

through the solenoid housing.

NOTE: The TEC output circuit that controls the fuel

stop solenoid also controls the electric fuel pump. This

circuit is known as the Energize To Run (ETR) circuit.

Refer to the Electrical Schematics and Wire Harness

Drawings in Chapter 8 − Foldout Drawings in this manu-

al for additional information.

Testing

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Unlatch and raise hood.

2. Test the ETR circuit as a TEC electrical output using

the Diagnostic Display (see Diagnostic Display in this

chapter). If output testing verifies that the TEC is ener-

gizing the ETR circuit under the appropriate conditions,

leave the diagnostic display connected and test the cir-

cuit wiring.

3. Test the circuit wiring:

A. Disconnect wire harness connector from the fuel

stop solenoid.

B. Position the necessary input(s) to illuminate the

ETR output LED indicating that the TEC controller is

energizing that function (see Table 3: Input Condi-

tions Required to Illuminate Diagnostic Display Out-

puts in this chapter).

C. Connect multimeter (DC voltage setting) across

the terminals of the wire harness connector. 12VDC

should be present at the connector when the ETR

LED is illuminated.

D. Repair damaged wiring as necessary.

4. If the circuit wiring is functioning correctly, use the fol-

lowing procedure to test the fuel stop solenoid.

NOTE: Prior to taking small resistance readings

with a digital multimeter, short the test leads togeth-

er. The meter will display a small resistance value

(usually 0.5 ohms or less). This resistance is due to

the internal resistance of the meter and test leads.

Subtract this value from the measured value of the

component you are testing.

A. Using a digital multimeter, touch one test lead to

the pull coil terminal and the other test lead to the fuel

stop solenoid frame (ground) (Fig. 40). The resis-

tance of the pull coil should be less than 1 ohm (but

not zero).

B. Using a digital multimeter, touch one test lead to

the hold coil terminal and the other test lead to the

fuel stop solenoid frame (ground) (Fig. 40). The re-

sistance of the hold coil should be approximately 15

ohms.

5. Replace solenoid if necessary and reconnect the

wiring harness.

1. Fuel stop solenoid 2. Harness connector

Figure 39

2

1

1. Fuel stop solenoid

2. Pull coil terminal

3. Hold coil terminal

Figure 40

2

3

1

Electrical

System