Groundsmaster 5900/5910 Hydraulic SystemPage 4 -- 29

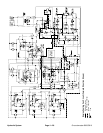

Engine Cooling Fan Circuit

A three section gear pump is coupled to the piston (trac-

tion) pump. The gear pump section (P3) farthest from

the piston pump supplies hydraulic flow to the steering/

cooling fan control manifold, the lift control manifold and

the traction charge circuit. Hydraulic flow from pump

section (P3) is split between the steering/cooling fan/

charge circuit and the lift/lower circuit by a proportional

flow divider located in the lift control manifold. This flow

divider splits pump flow approximately 75% for the

steering/cooling fan/charge circuit (10.5 GPM/39.7

LPM) and 25% for the lift/lower circuit (3.5 GPM/13.2

LPM).

The steering/cooling fan control manifold controls the

operation of the steering control valve and the gear mo-

tor that drives the engine cooling fan. Priority valve (PV)

in the manifold controls the oil flow to the steeringcontrol

valve which is a closed center, load sensing valve. The

steering control valve senses the oil flow that is needed

for steering and the priority valve (PV) will supply the

correct amount. Oil not used by steering is provided to

the fan motor. The steering/cooling fan control manifold

controls the speed and direction of the fan motor based

on electrical output from the TEC--5002 controller.

With the steering wheel in the neutral, at rest position

and the engine running, hydraulic oil from the lift control

manifold flow divider enters the steering/cooling fan

control manifold port P, flows through the priority valve

(PV) and to the steering control valve where it dead

heads at the spool. Oil is also sent to both ends of the

(PV) spool. On one end of the spool, oil is directed to the

steering relief valve (RV) and also is directed through

the OR orifice and out the LS manifold port to the steer-

ing control valve. This flow provides steering load sense

pressure and is directed through a small passage in the

steering control valve spool and sleeve before returning

to the charge circuit. While this load sense pressure is

returning to the charge circuit, the priority valve (PV)

spool shifts to direct pump flow to the cooling fan motor

circuit. Without steering input, no oil is flowing through

the steering control valve so all circuit oil is available for

thecoolingfanmotor.

Oil flow from the priority valve (PV) to the cooling fan is

controlled by the proportional relief valve (PRV). The

(PRV) adjusts fan circuit pressure and flow based on a

PWM (Pulse Width Modulation) signal from the

TEC--5002 controller. The controller uses engine cool-

ant and hydraulic oil temperatures to determine the

proper PWM signal for the (PRV) valve. The fan circuit

flow determines the speed of the cooling fan.

If the fan motor is stalled for any reason, the priority

valve (PRV) has a secondary function as a circuit relief

to limit fan motor pressure to 3300 PSI (228 bar).

When the engine is shut off, the over--running inertia

load of the fan blades keeps driving the fan motor and

turns it into a pump. The check valve (CV) in the steer-

ing/cooling fan control manifold will open to keep the

motor circuit full of oil so the fan motor will not cavitate.

Forward Direction Fan Operation

Oil flow from the priority valve (PV) is sent through the

de--energized solenoid valve (S), out manifold port M1

and then to rotate the cooling fan motor. Return flow

from the motor enters the manifold at port M2, through

the de--energized solenoid valve (S), out manifold port

CH and is then used for traction circuit charge oil.

Reverse Direction Fan Operation

The TEC--5002 controller can reverse the cooling fan to

clean debris from the radiator, oil cooler and rear intake

screen. If hydraulic oil and/or engine coolant tempera-

tures increase to an unsuitable level, the PWM signal to

the (PRV) valve is sent to slow the cooling fan. The con-

troller then energizes solenoid valve (S) in the steering/

cooling fan control manifoldto reversecooling fan motor

oil flow so that it runs in the reverse direction. The con-

troller determines the length of time that the fan should

be run in reverse before fan rotation is returned to the

forward direction.

Hydraulic

System