Groundsmaster 5900/5910 Page 3 -- 7 Diesel Engine

Adjustments

Valve Clearance

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parking brake and remove

key from the ignition switch.

2. Raise and support hood.

3. Remove valve c over from engine (see Valve Cover

Removalinthe ServiceandRepairs section ofthischap-

ter).

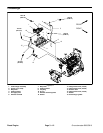

4. Position engine crankshaft so cylinder #1 is at top

dead center (TDC) at the end of the c ompression stroke:

A. While watching the movement of the cylinder #4

intake valve, rotate enginecrankshaftin normal rota-

tion direction (clockwise). When the cylinder #4 in-

take valve starts to open, cylinder #1 is approaching

TDC at the end of the compression stroke.

B. Continue rotating the crankshaft in the normal

rotation direction ( clockwise) until the cutout in the

tone wheel attached to the back of the crankshaft

pulleyalignswith“1.4TOP” cast inenginefrontcover

(Fig. 1).

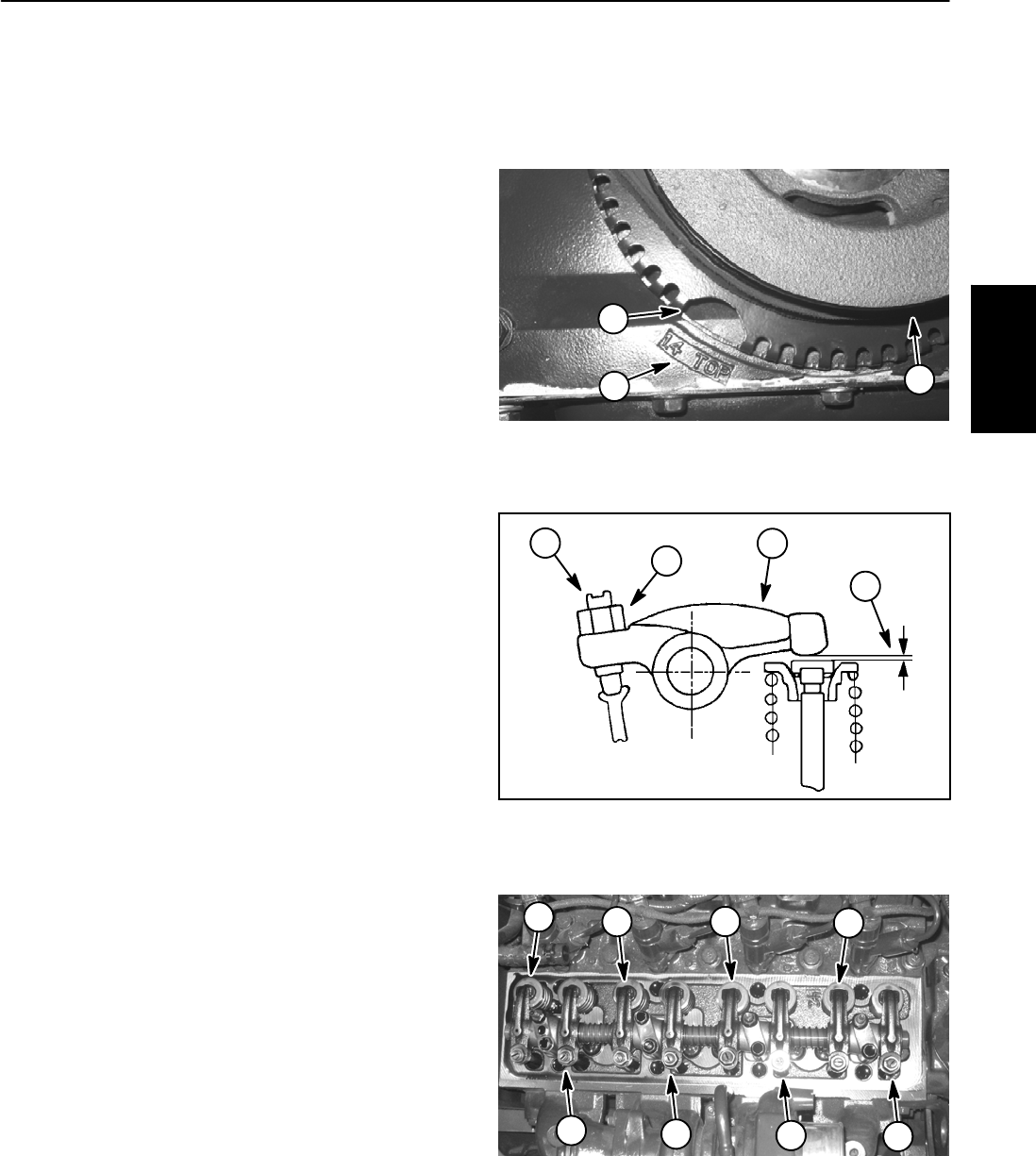

5. In this crankshaft position, adjust valve clearance for

intake valves for cylinders #1 and #3 and exhaust valves

for cylinders #1 and #2 (Fig. 2 and 3).

A. Loosen the lock nuton the rocker armadjustment

screw.

B. Insert correct feeler gauge between the valve

stem and the rocker arm. Intake v alve clearance

specification is 0.014” (0.35 mm). Exhaust valve

clearance specification is 0.020” (0.50 mm).

C. Adjust screw until a slight drag is felt on the feeler

gauge.

D. Hold adjustment screw in position and tighten

lock nut to secure valve clearance adjustment.

Torque lock nut from 29 to 36 ft--lb (39 to 49 N--m).

E. After tightening lock nut, r e--check valve clear-

ance.

6. Rotate crankshaft in the normal rotation direction

(clockwise) one complete revolution. The tone wheel

cutout should again be aligned with “1.4 TOP”.

7. In this crankshaft position, adjust valve clearance for

intake valves for cylinders #2 and #4 and exhaust valves

for cylinders #3 and #4. Follow procedure under step 5

above.

8. Install valve cover to engine (see Valve Cover Instal-

lation in the Service and Repairs section ofthis c hapter).

9. Lower and secure hood.

Figure 1

1. Crankshaft pulley

2. Tone wheel cutout

3. TDC indicator

1

2

3

Figure 2

1. Lock nut

2. Adjustment screw

3. Rocker arm

4. Valve clearance

1

2

3

4

Figure 3

1. #1 intake

2. #1 exhaust

3. #2 intake

4. #2 exhaust

5. #3 intake

6. #3 exhaust

7. #4 intake

8. #4 exhaust

6

1

2

3

4

7

5

8

Diesel

Engine