Groundsmaster 5900/5910 Hydraulic SystemPage 4 -- 105

The control manifolds for the three cutting deck sections

are very s imilar. Note: When servicing the PTO control

manifolds, DO NOT interchange parts from one control

manifold to another.

NOTE: The ports on the PTO control manifolds are

marked for easy identification ofcomponents. Example:

Sisthesolenoid valve and M2 is the return from thedeck

motor (see Hydraulic Schematic in Chapter 10 -- Foldout

Drawings to identify the function of the hydraulic lines

and cartridge valves at each port).

Removal (Fig. 77)

1. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

2. To preventcontamination ofhydraulic system during

manifold removal, thoroughly clean exterior of manifold

and fittings.

3. Disconnect wire harness connector from the man-

ifold solenoid valve.

4. Disconnect hydraulic lines from manifold and put

caps or plugs on open hydraulic lines and fittings. Label

disconnected hydraulic lines for proper assembly.

5. Support PTO control manifold to prevent it from fal-

ling.

6. Remove two (2) cap screws and flange nuts that se-

cure manifold to frame. Remove PTO control manifold

from the frame.

7. If hydraulic fittings are to be removed from manifold,

mark fitting orientation to allow correct assembly. Re-

move fittings from manifold and discard O--rings.

Installation (Fig. 77)

1. If fittings were removed from manifold:

A. Lubricate new O--rings with clean hydraulic oil.

Install lubricated O--rings on fittings.

B. Install fittings into manifoldopenings using marks

made during the removal process to properly orien-

tate fittings.

C. Refer to Figures 78, 79 and 80 for straight fitting

installation torque. Forinformation on tightening pro-

cedures for adjustable fittings, see Hydraulic Fitting

Installation in the General Information section of this

chapter.

2. Position PTO control manifold to the frame and se-

cure with two (2) cap screws and flange nuts.

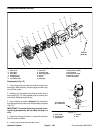

1. Front PTO manifold

2. O--ring

3. Quick fitting

4. Dust cap

5. O--ring

6. Hydraulic 45

o

fitting

7. O--ring

8. Hydraulic 45

o

fitting

9. O--ring

10. O--ring

11. O--ring

12. Hydraulic tee fitting

13. O--ring

14. Hydraulic 90

o

fitting

Figure 78

6

14

10

8

2

3

1

11

9

7

12

13

4

5

5

7

7

20 ft--lb

(27 N--m)

UP

FRONT PTO MANIFOLD

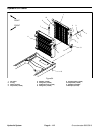

1. RH PTO manifold

2. O--ring

3. Quick fitting

4. Dust cap

5. O--ring

6. Hydraulic 90

o

fitting

7. O--ring

8. O--ring

9. Hydraulic tee fitting

10. O--ring

11. Hydraulic 90

o

fitting

12. O--ring

13. O--ring

14. Straight fitting

Figure 79

6

10

8

2

3

1

11

9

7

12

13

4

5

5

7

8

14

20 ft--lb

(27 N--m)

75 ft--lb

(101 N--m)

UP

RH PTO MANIFOLD

Hydraulic

System