Reelmaster 2300–D/2600–DHydraulic System Page 4 – 50

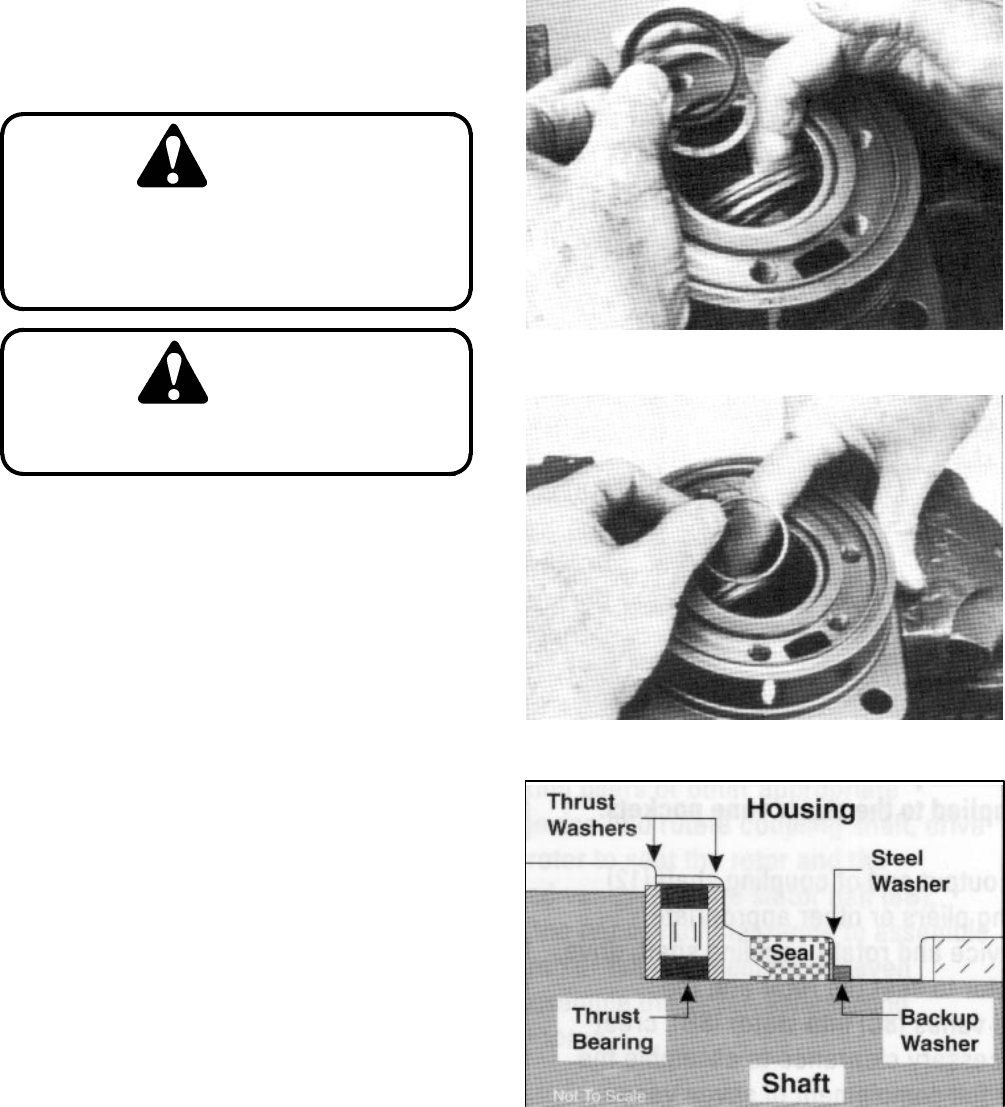

Reassembly (Fig. 32)

1. Lubricate all seals and seal rings with clean hydrau-

lic oil before assembly.

Since they are flammable, be extremely

careful when using any solvent. Even a

small explosion or fire could cause injury

or death.

WARNING

CAUTION

Use eye protection such as goggles when

using compressed air

2. Wash all parts in a clean petroleum–based solvent

before assembly. Blow parts dry with compressed air.

3. Press a new dirt and water seal (1) into the housing

(3) outer bearing counterbore. Press seal in with the lip

facing out and until the seal is 0.020 inch (0.51 mm) be-

low the end of housing.

4. Place housing (3) into a soft jawed vise with the cou-

pling shaft bore down; clamp against the mounting

flange.

IMPORTANT: Early model wheel motors that do not

have backup washer (6) when inspected must be as-

sembled with a new backup washer (4), new backup

washer (6), and new seal (7).

5. A housing (3) that does not require replacement will

require that the two thrust washers (8) and thrust bear-

ing (9) be unseated and vertical to the counterbore and

the new backup washer (4), new backup washer (6),

and new seal (7) be worked around the thrust bearing

package and placed into their respective counterbores

(Fig. 44 and 43). The seal lip must face out of the seal

counterbore and toward the inside of wheel motor (Fig.

45). Be sure the thrust bearing package is reseated cor-

rectly after assembly of the new seal and backup wash-

ers.

6. Apply masking tape around splines or keyway on

coupling shaft (11) to prevent damage to seal.

IMPORTANT: The outer bearing (2) is not lubricated

by the system’s hydraulic fluid. Make sure it is thor-

oughly packed with the recommended grease.

Figure 43

Figure 44

Figure 45

Note: Coupling shaft (11) should be approximately

0.10 inch (2.54 mm) below the housing wear plate sur-

face to allow the assembly of thrust bearing (12). The

coupling shaft must rotate smoothly on the thrust bear-

ing (9) and thrust washer (8) (Fig. 46).

7. Make sure that a generous amount of clean corro-

sion resistant grease has been applied to the outer bear-

ing (2). Install the coupling shaft (11) into housing (3),

and seat shaft against the second thrust washer (8).