Reelmaster 2300–D/2600–DHydraulic System Page 4 – 34

Adjustments

Transmission for Neutral

If the machine “creeps” when the traction control pedal

is in the neutral position, the neutral return mechanism

must be adjusted.

1. Block up under the frame so one of the front wheels

is off the floor. Place selector control in two wheel drive

position.

2. Start engine, move throttle to SLOW and check front

wheel that is off shop floor; it must not be rotating. Loos-

en pump plate nuts and rotate pump plate until creep

does not occur in either direction. When wheel stops ro-

tating, tighten nuts locking adjustment. Verify the adjust-

ment with throttle in SLOW and FAST position.

3. Should the wheel continue to rotate, check for the

following:

A. Ball bearing is loose or worn out.

B. Loose or missing fasteners.

C. Worn fasteners.

D. Pump lever loose on control shaft.

E. Weak or damaged Ieaf springs. Replace.

F. Internal pump component malfunction.

4. After adjusting the pump plate, check neutral switch

operation and if necessary, adjust as follows:

A. Loosen locknut securing switch adjusting screw.

Thread away from switch until capscrew head

clears switch.

B. Rotate adjusting screw toward switch until circuit

through switch is made. Then, turn adjusting screw

an additional 2–1/2 turns.

C. Tighten locknut

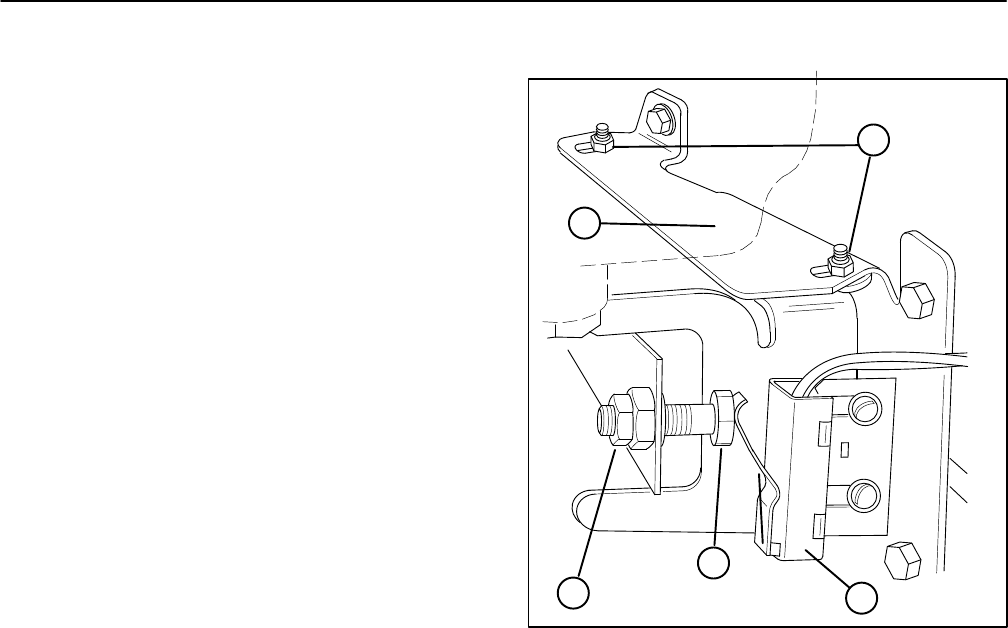

1. Pump plate nut

2. Pump

3. Neutral switch

4. Adjusting screw

5. Lock nut

Figure 19

3

4

5

1

2