Reelmaster 2300–D/2600–D

Page 5 – 31

Electrical System

Traction (Electric) Clutch (Fig. 27 through 31)

The clutch circuit is normally energized when the engine

is starting or running. When energized, an electromag-

net pulls the armature into contact with the rotor to drive

the pulley and the traction motor through a fan belt.

Failure to engage the clutch is likely caused by too large

of a clutch air gap, a circuit fault in the clutch electromag-

net, or another electrical problem (see Wiring Schemat-

ics).

Note: The air gap is not adjustable. The clutch must

be serviced as a whole and individual parts can not be

replaced.

Removal

1. Make sure the engine is off and the fuel solenoid is

disconnected.

2. Lift the hood and disconnect the clutch electrical

connection. Make sure the connection is free of the

cable harness and the R–bracket holding it to the engine

block.

3. Remove the right and left front panels to access the

clutch and U–bracket support.

4. Remove the flanged nut securing the dampener to

the traction arm. Remove nut, lock washer and flat

washer securing the dampener to the U–bracket sup-

port. Remove the dampener (Fig 27).

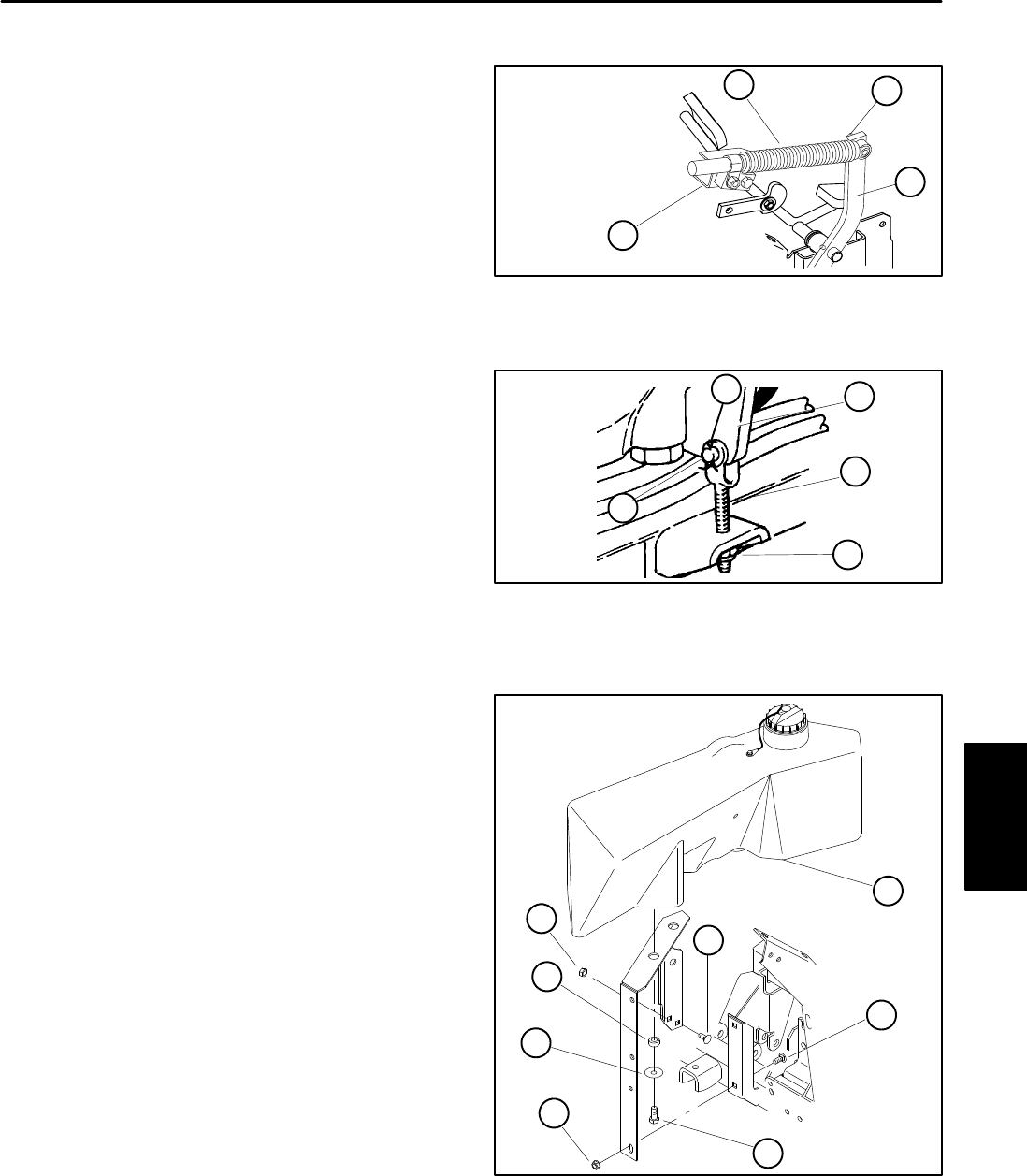

5. Remove the two bolts, flat washers, and grommets

holding the tank to the U–bracket support. Remove the

nuts, carriage bolts, and U–bracket support from the

frame (Fig. 29).

6. Loosen nut on adjusting yoke. Remove the cotter

and clevis pins from the adjusting yoke. Tilt pump mount

and remove the pump belt (Fig 28).

7. Remove long capscrew with the jam nut from en-

gine block. Retain the position of the jam nut on the

capscrew (Fig. 30).

8. Remove the spindle with the clutch attached by al-

ternately loosening all spindle capscrews and then pull-

ing on the clutch (Fig. 30). When the spindle is free of the

fly wheel, slide it up along the flywheel and rotate it out

to clear the traction pedal and foot rest.

9. Remove the capscrews, lock washers, and pulley

from the clutch (Fig. 30).

10. Remove the capscrew, lockwasher, and flat washer

from the spindle. Slide the clutch and key from the clutch

spindle (Fig. 30).

1. Flanged nut

2. Dampener

3. Traction arm

4. U–bracket support

Figure 27

4

1

2

3

1. Nut

2. Cotter pin

3. Clevis pin

4. Adjusting yoke

5. Pump mount

Figure 28

2

2

1

4

5

Figure 29

1. Capscrew

2. Flat washer

3. Grommet

4. Hydraulic tank

5. Nut

6. Carriage bolt

4

5

1

2

3

6

6

5

Electrical

System