Reelmaster 2300–D/2600–D Hydraulic SystemPage 4 – 41

13. Remove retaining ring (37) from the bore on the

flange end of the housing assembly (15). Press the shaft

(31), shaft seal (36), and washer (35) from the housing

assembly.

14. Remove retaining ring (32), washer (35), thrust

bearing (34), second washer (35), and second retaining

ring (32) from the shaft (31).

15. Remove screws (7), trunnion cover (8), O–ring cov-

er (9), O–ring (10), washer (11), inner race (12), and

bearing (13). Remove screws (7), seal cover (16), shaft

seal (17), washer (11), and bearing (13).

16. Position camplate (20) to one side and remove from

the housing assembly (15).

Inspection

CAUTION

Use eye protection such as goggles when

using compressed air

1. Wash all parts in solvent. Dry parts with compressed

air.

2. Inspect charge pump adapter assembly (see Fig.

25).

A. Check relief valve seat inside suction port. Make

sure that seat is smooth and free of burrs or other

defects. Relief valve spring must not be damaged.

B. Bearing needles must remain in bearing cage

and move freely. Verify that bearing depth on the

flange side meets the dimension in Figure 27.

C. Make sure gerotor pocket inside the pump is not

excessively scored.

3. Inspect backplate assembly (25) (see Fig. 24).

A. Bearing needles must remain in bearing cage

and move freely. Verify that bearing height on the

numbered end meets the dimension in Figure 28.

B. Check that the roll pin is tight and meets the

height in Figure 28.

C. Replace entire assembly as a unit.

4. Inspect camplate assembly (20) (see Fig. 24).

There should be no signs of scoring on the piston shoe

surfaces.

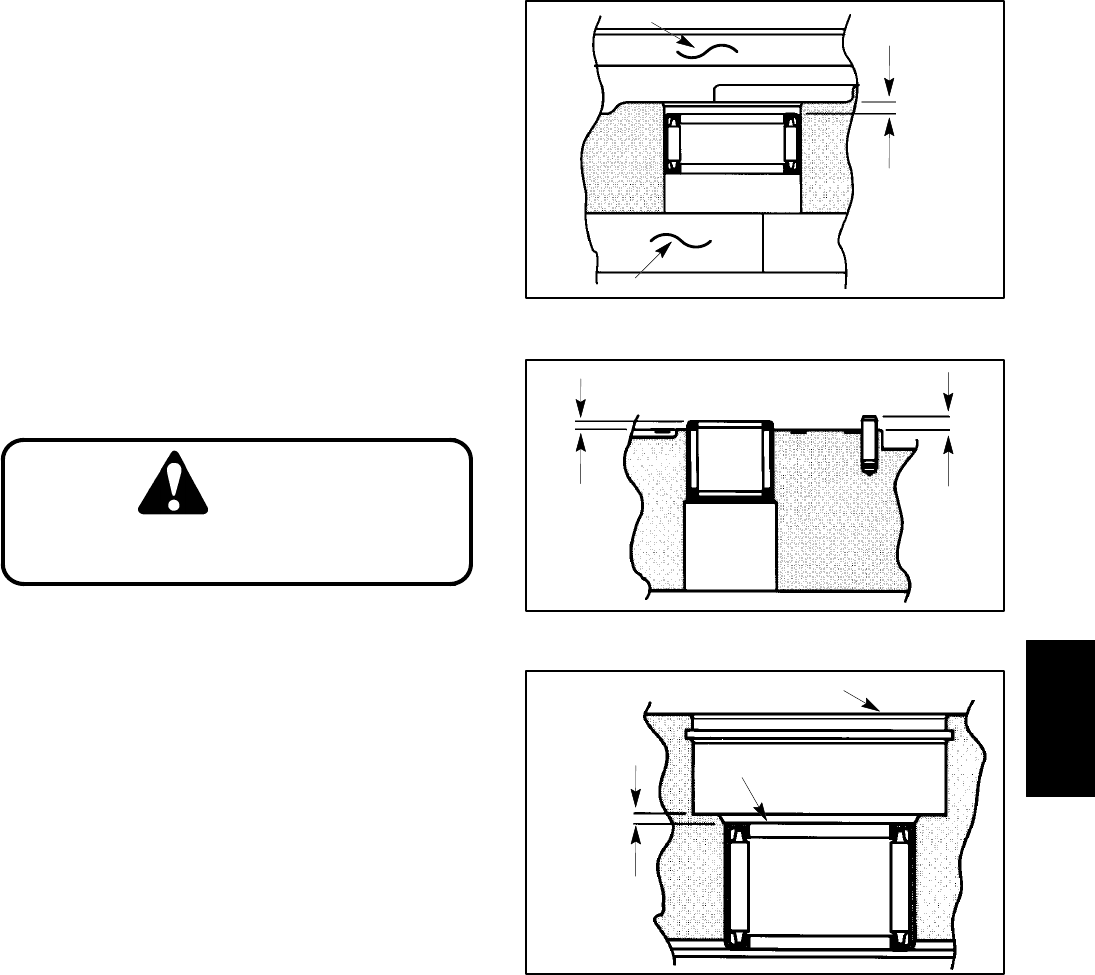

Figure 27

GEROTOR POCKET

FLANGE

BEARING

DEPTH

0.090 to 0.100 in.

(2.54 to 2.89 mm)

Figure 28

BEARING

HEIGHT

ROLL PIN

HEIGHT

0.070 to 0.080 in.

(1.78 to 2.03 mm)

0.105 to 0.115 in.

(2.67 to 2.92 mm)

Figure 29

BEARING

DEPTH

NUMBERED END

FLANGE END OF HOUSING

0.062 to 0.078 in.

(1.57 to 1.98 mm)

5. Inspect housing assembly (15) (see Fig. 24).

A. Verify that bearing depth on the numbered end

meets the dimension in Figure 29.

B. Bearing needles must move freely and remain in

their cage.

Hydraulic

System

Hydraulic

System